Novel multifunctional sludge heat pump drying machine

A multi-functional, drying machine technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, energy and wastewater treatment, etc., can solve the problem of poor sludge drying effect and sludge drying effect. problems such as uneven heating of sludge, low maintenance costs in the later period, extended conveying distance and drying time, and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

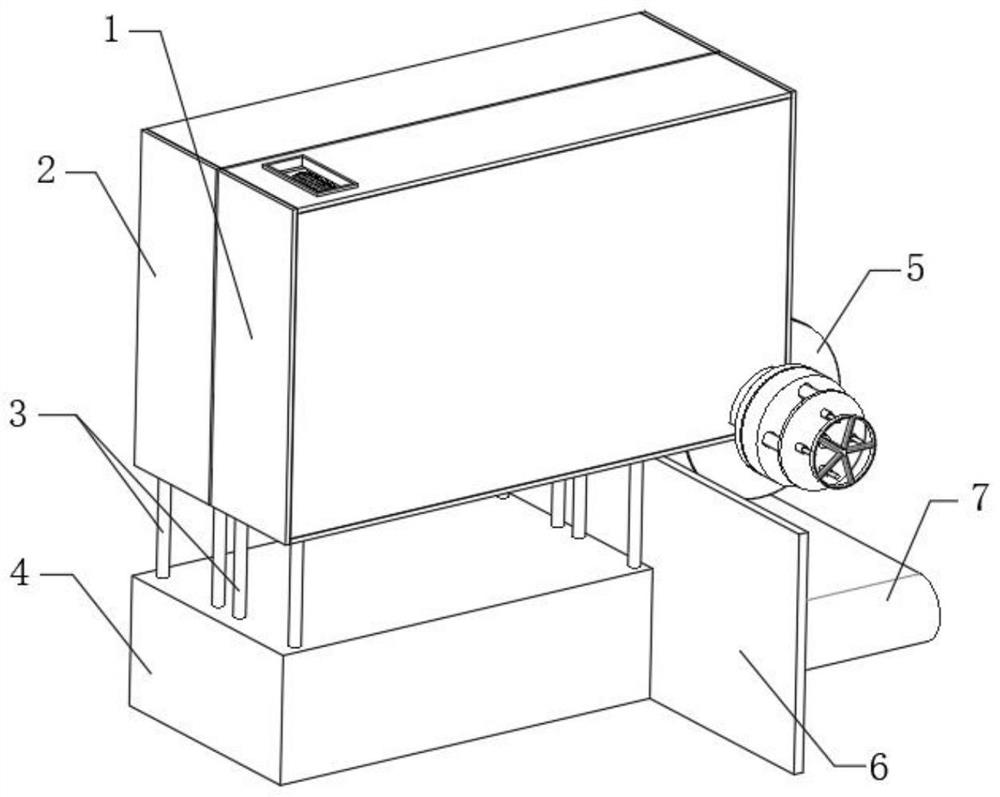

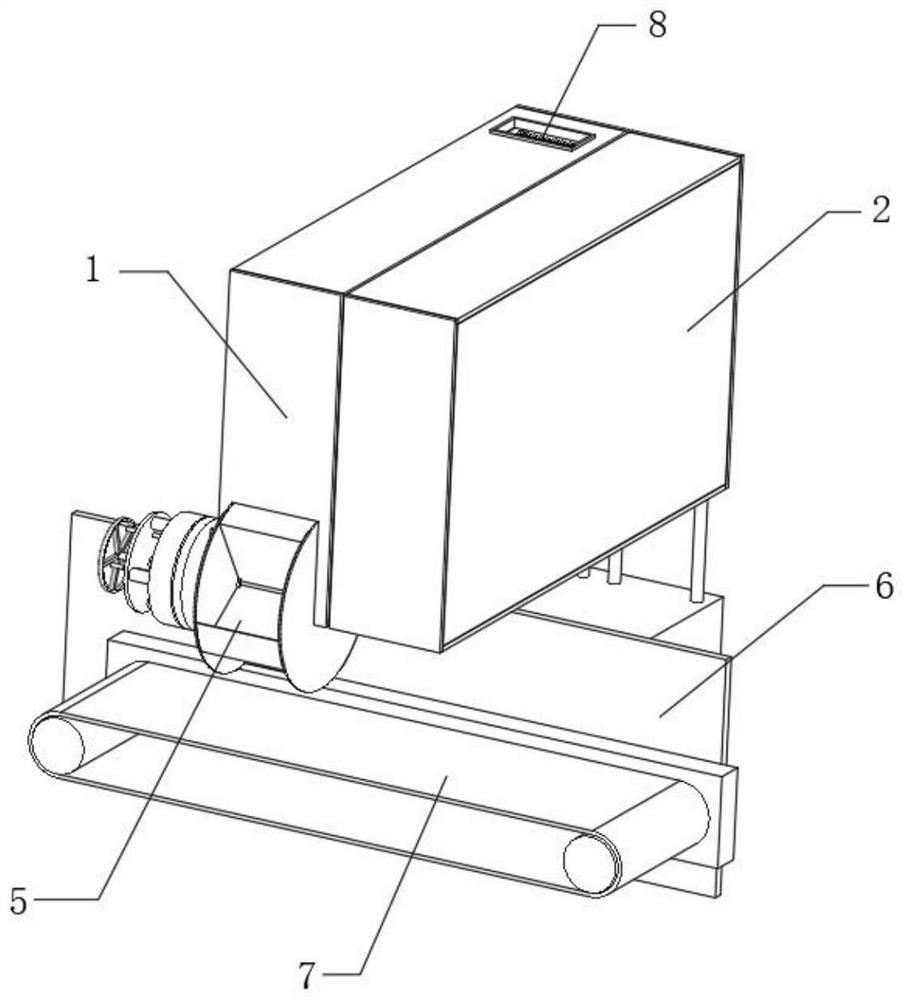

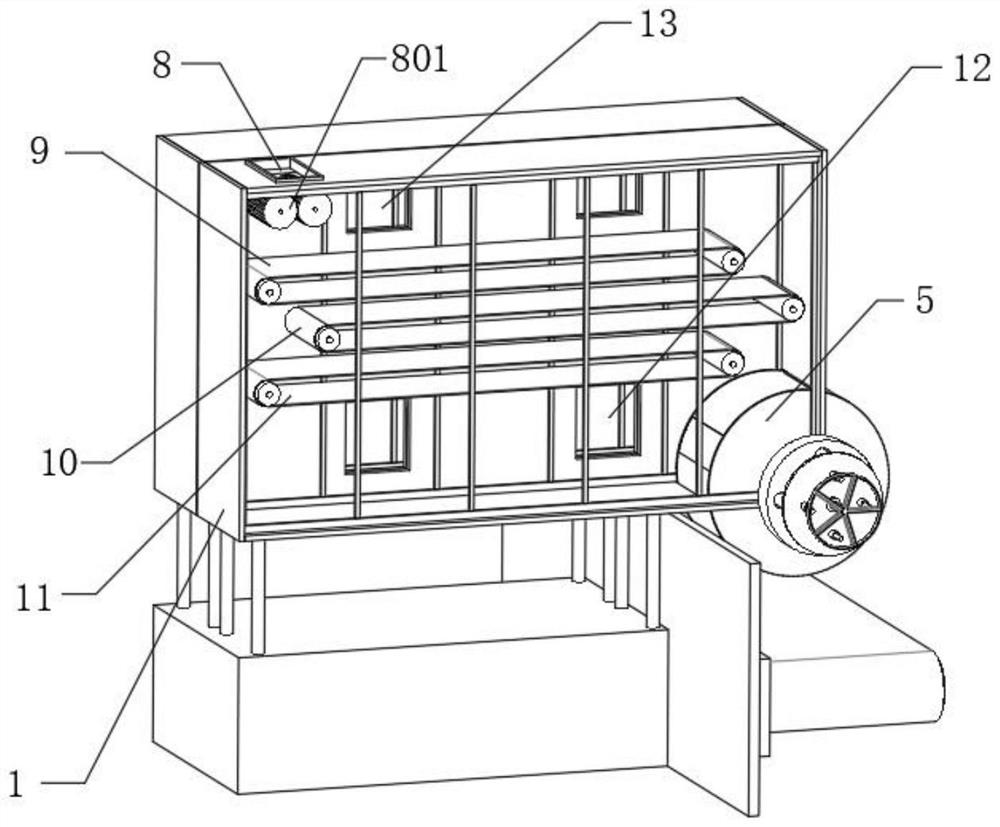

[0080] A new type of multi-functional sludge heat pump drying machine, such as Figure 1-11 As shown, including:

[0081] The drying box main body 1, the bottom of the drying case body 1 is provided with a support table 4, and the inside of the drying case body 1 is provided with a first drying box conveyor belt 9, a second drying tank conveyor belt 10, and a third drying tape 11;

[0082] The ventilation system carrier box 2, the ventilation system carrier box 2 is fixed to the bottom support frame 3, the bottom support frame 3 is fixedly connected to the support station 4, and the ventilation system carrier box 2 and the drying box main body 1 are fixedly connected to the support station 4. There is an oven bottom airway 12 and the top of the oven 13;

[0083] The feed port 8, the feed port 8 is disposed at the top of the drying box main body 1, and the feed port 8 is provided with a sludge cutting machine 801;

[0084] The discharge mechanism 5, the discharge mechanism 5 is disp...

Embodiment 2

[0095] A new type of multi-functional sludge heat pump drying machine, such as Figure 1-11 As shown, including:

[0096] The drying box main body 1, the bottom of the drying case body 1 is provided with a support table 4, and the inside of the drying case body 1 is provided with a first drying box conveyor belt 9, a second drying tank conveyor belt 10, and a third drying tape 11;

[0097] The ventilation system carrier box 2, the ventilation system carrier box 2 is fixed to the bottom support frame 3, the bottom support frame 3 is fixedly connected to the support station 4, and the ventilation system carrier box 2 and the drying box main body 1 are fixedly connected to the support station 4. There is an oven bottom airway 12 and the top of the oven 13;

[0098] The feed port 8, the feed port 8 is disposed at the top of the drying box main body 1, and the feed port 8 is provided with a sludge cutting machine 801;

[0099] The discharge mechanism 5, the discharge mechanism 5 is disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com