Pressure reducing and stabilizing valve

A pressure-stabilizing valve and spool technology, applied in the field of decompression and pressure-stabilizing valves, can solve the problem that the fire extinguishing agent is difficult to penetrate, and achieve the effects of increasing the range of protection, increasing the delivery distance, and increasing the storage pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

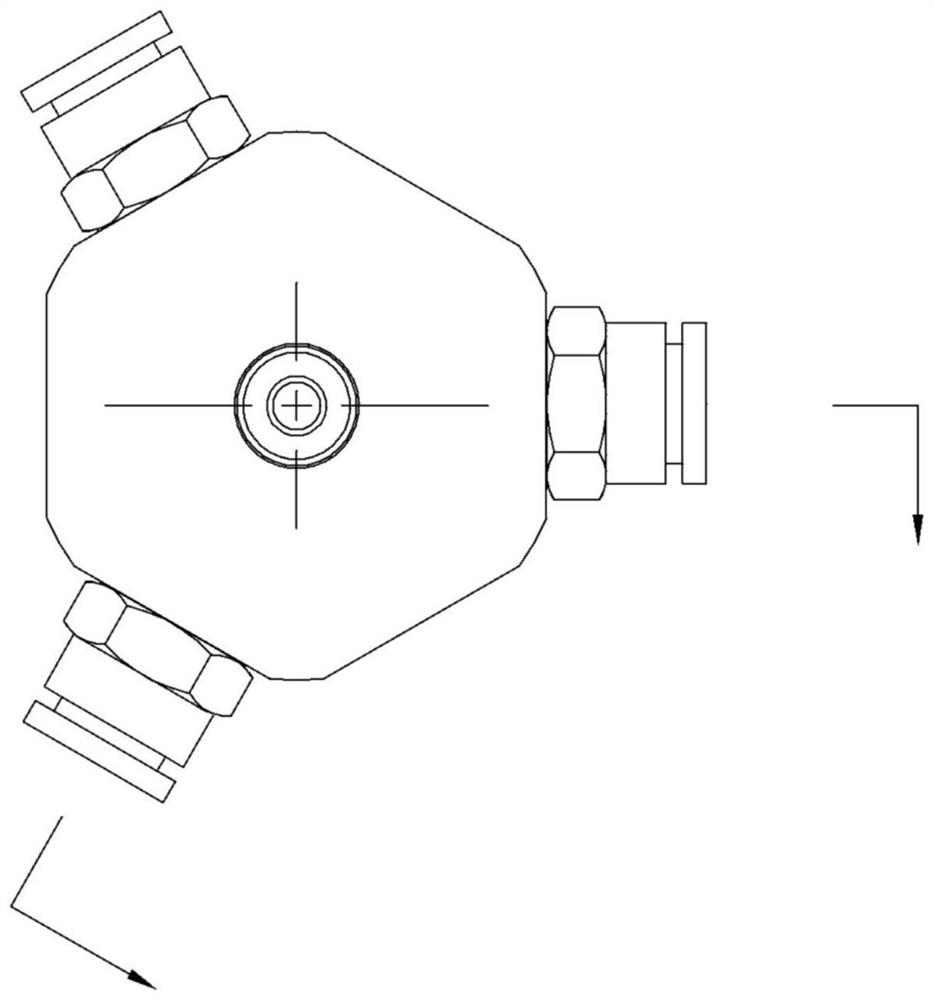

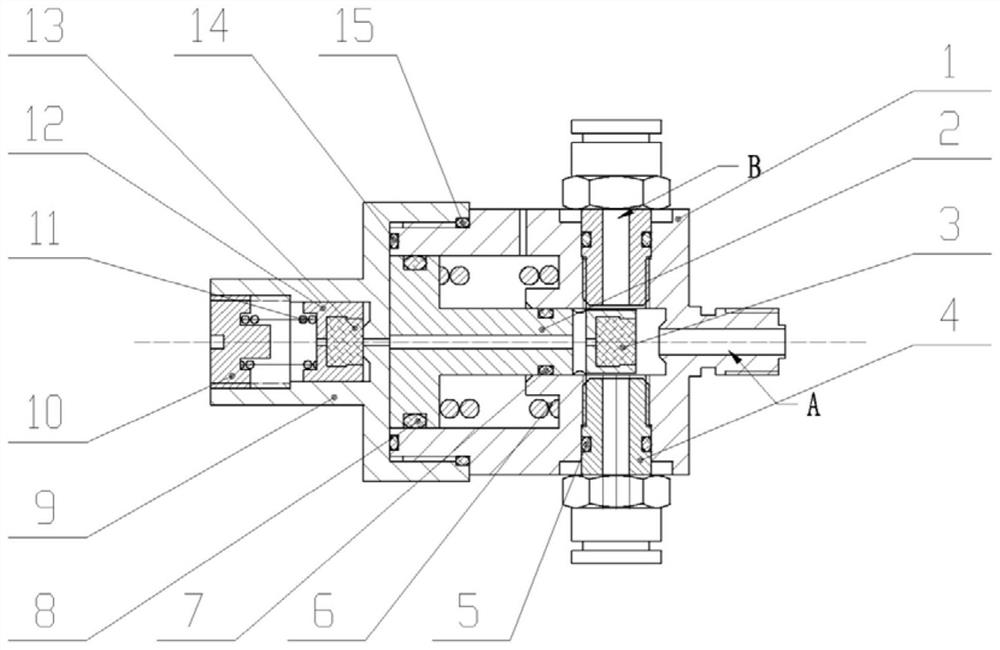

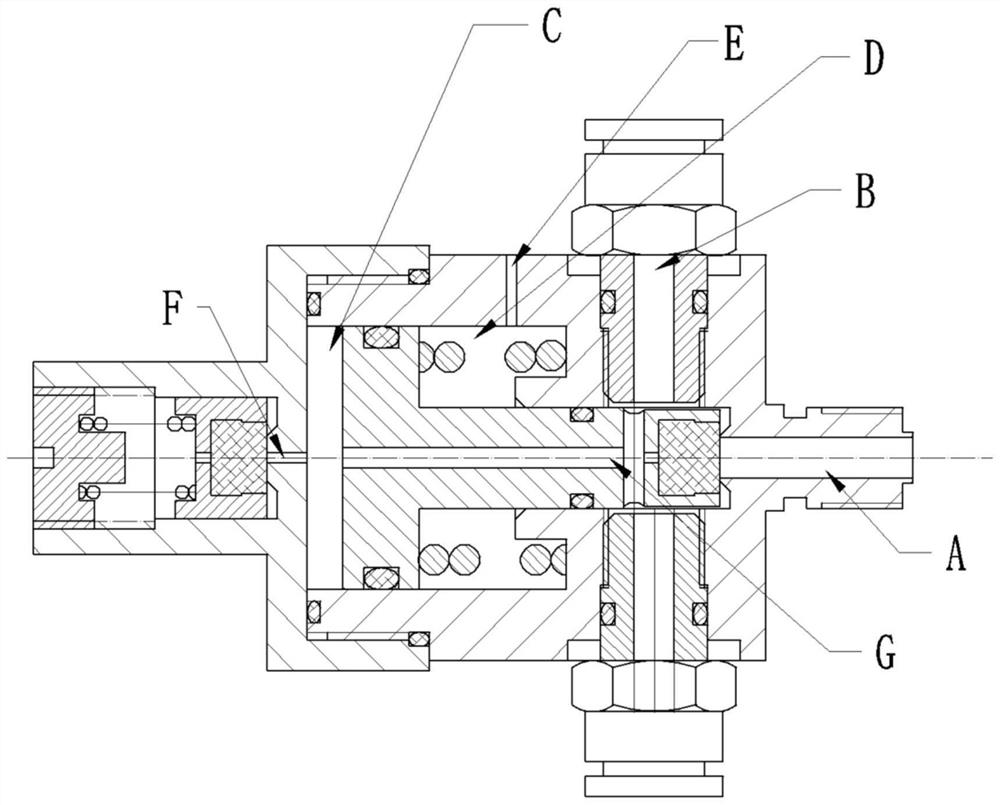

[0019] Such as figure 1 , 2 A pressure reducing and stabilizing valve shown in 3, a pressure reducing and stabilizing valve, comprising a valve body 1, a valve core 2 installed inside the valve body, a first end face gasket 3 is arranged in the valve body at the upper end of the valve core , the two sides of the first end face gasket 3 are provided with hose joints 4, the hose joints are provided with O-ring I5, the valve body is also provided with a first pressure regulating spring 6, and the front of the valve core is provided with O-ring II7, There is an O-ring III8 at the rear of the valve core, a valve cover 9 is connected to the rear of the valve body, a pressure regulating base 10 is embedded in the valve cover, and a second pressure regulating spring 11 is provided on the front side of the pressure regulating base. The front end of the spring leans against the second valve core 12, and the front end of the second valve core is provided with a second end face gasket 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com