Ceramic chip electrode printing machine

A chip electrode and printing machine technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of ceramic chips falling off, reducing the adsorption effect of the turnover mechanism, etc., and achieve the effects of avoiding falling off, lowering the temperature, and expanding the conveying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

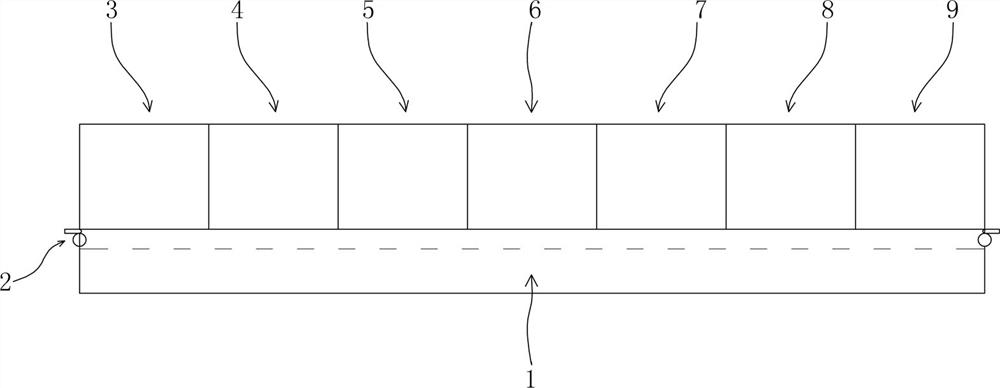

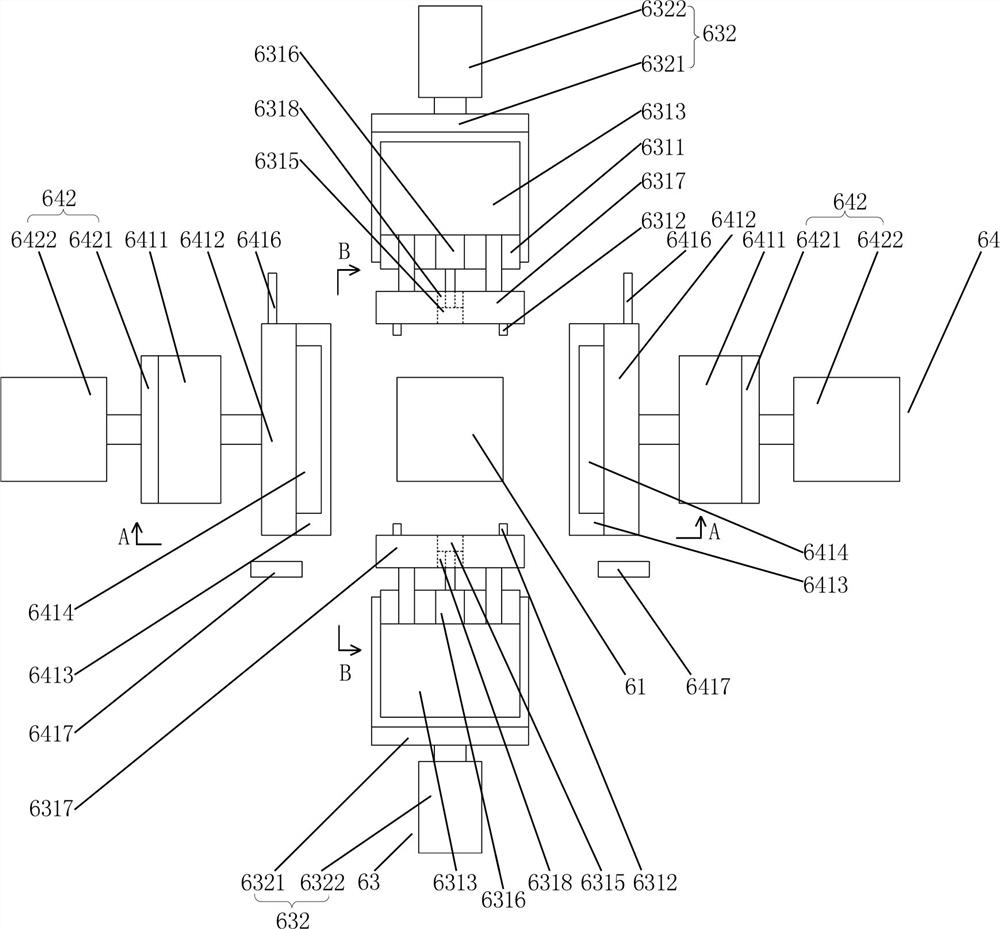

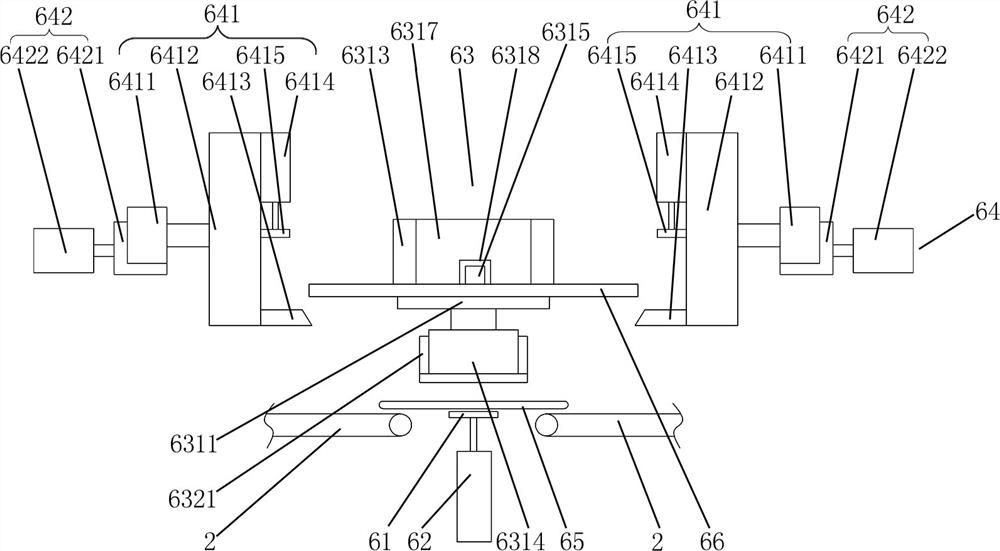

[0044] Such as figure 1 As shown, a ceramic chip electrode printing machine includes a frame 1, a conveying mechanism 2 arranged on the frame 1, and a primary painting device 3 and a primary drying device sequentially arranged on the frame 1 along the conveying mechanism 2. 4. Primary cooling device 5 , plate turning device 6 , secondary painting device 7 , secondary drying device 8 and secondary cooling device 9 . In order to save text descriptions and reduce the number of drawings, in this embodiment, the aforementioned conveying mechanism 2, primary brushing device 3, primary drying device 4, secondary brushing device 7 and secondary drying device 8 all adopt this application People's online patent "An Automatic Silver Printing Machine" (authorized announcement number: CN210136892U), the specific structure can refer to the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com