Long-distance wet type concrete spraying method

A concrete spraying and long-distance technology, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve the problems of higher pipeline sealing performance, high labor intensity of construction personnel, and high wind pressure requirements, so as to reduce pipeline blockage Occurrence probability, small footprint, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

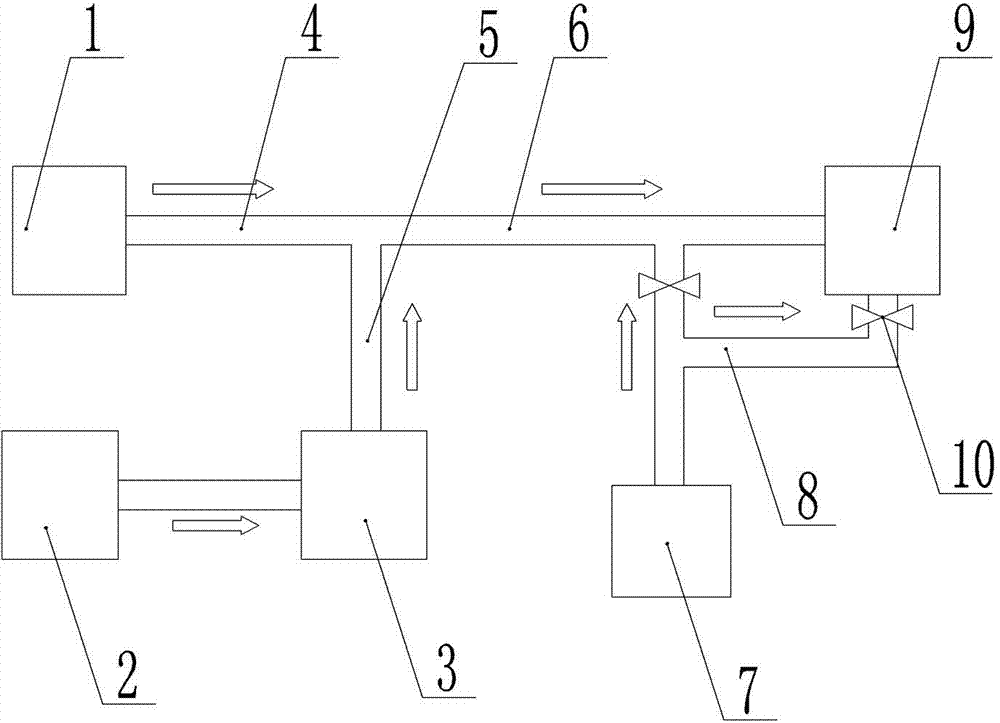

[0016] Embodiment one: see figure 1 , a long-distance wet concrete spraying method, including three conveying pipelines of sandstone conveying pipeline 4 containing powdery quick-setting agent, cement conveying pipeline 5 and high-pressure waterway 8. In the pipeline 4, the stirred sand and gravel mixture containing the powdered quick-setting agent is transported into the sand and gravel conveying pipeline 4 through the sand and gravel conveying device 1; The medium is conveyed into the cement conveying pipeline 5 by the cement conveying device 3, and the end of the cement conveying pipeline 5 is connected with the gravel conveying pipeline 4 and enters the mixing pipeline 6. There are two connecting nozzles and the mixing pipeline 6 at a distance of 0 to 15 meters from the nozzle. The high-pressure waterway 8 is respectively provided with a water volume regulating valve 10 on the high-pressure waterway 8 for adjusting the water-cement ratio.

[0017] When spraying, first tur...

Embodiment 2

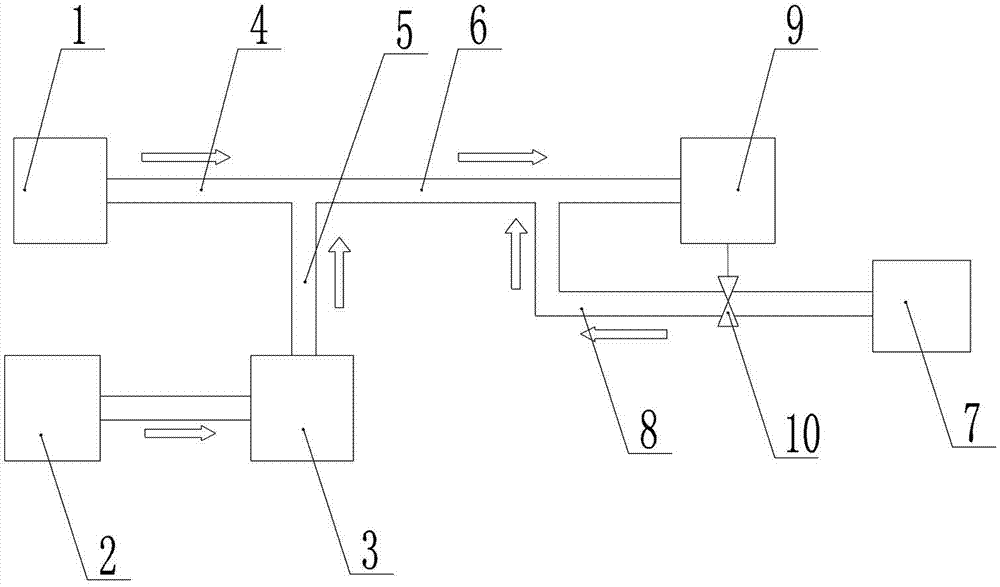

[0018] Embodiment two: see figure 2 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the high-pressure water circuit passes through the valve fixed at the nozzle and then connects with the valve at 0 to 15 meters away from the nozzle. The pipes are connected, so that under the premise of ensuring the full mixing of the three materials, it is convenient for the sprayer holding the nozzle to adjust the water volume nearby, reduce the rebound rate, and improve the spray quality.

Embodiment 3

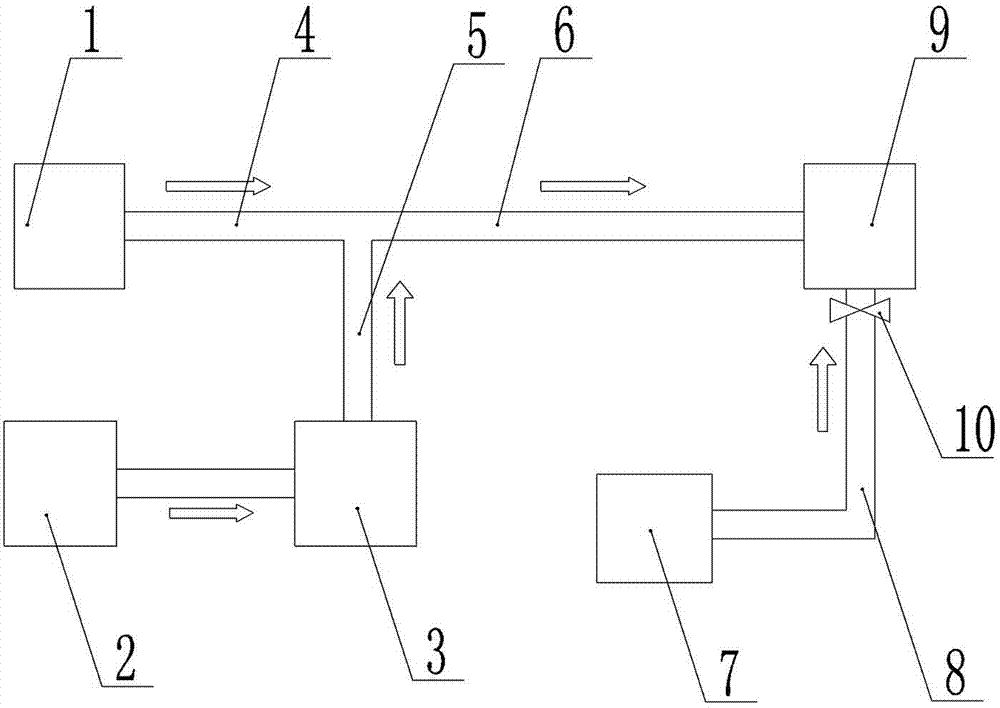

[0019] Embodiment three: see image 3 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the high-pressure water circuit is directly connected to the nozzle after passing through the valve, which can maximize the spraying distance and reduce the The residence time of the mixture of cement and water in the pipeline is convenient to keep the pipeline unimpeded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com