Ultra-distance steam conveying pipeline

A steam pipeline and ultra-long-distance technology, applied in the field of ultra-long-distance transportation of steam pipelines and steam pipelines, can solve the problems of large load fluctuation, unrealizable technology, poor economy, etc., to reduce exhaust emissions, improve energy efficiency, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

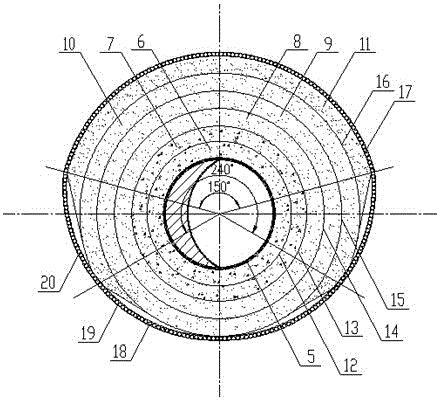

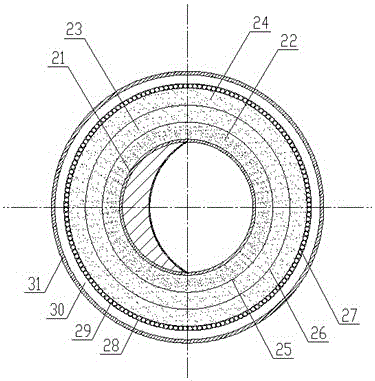

[0030] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0031] The invention provides an ultra-long-distance steam transport pipeline, which includes a superheated steam section and a superheated / saturated steam section. Both the superheated steam section and the superheated / saturated steam section include overhead steam pipes and buried steam pipes.

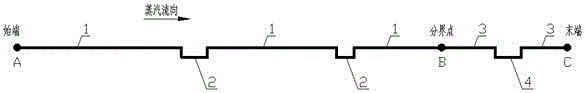

[0032] figure 1 It is a schematic diagram of the ultra-long-distance transport steam pipe of the present invention.

[0033] Such as figure 1Shown: Steam is transported from the beginning A to the end C, where B is the dividing point (that is, the dividing point between the superheated steam section and the superheated / saturated steam section), from point B to point C, when the maximum load or average load is delivered, it is superheated Steam, which is saturated steam when delivering the minimum load. The steam transportation distance is lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com