High polymer deep hole positioning self-enclosed slurry nozzle and slurry system and method thereof

A grouting system and self-sealing technology, used in earth-moving drilling, soil protection, marine engineering, etc., can solve the problems of high friction resistance, difficult realization, and inability to accurately locate and dispose of multi-layer geological defects, and achieve elongated transportation. distance, the effect of extending the distance of slurry transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

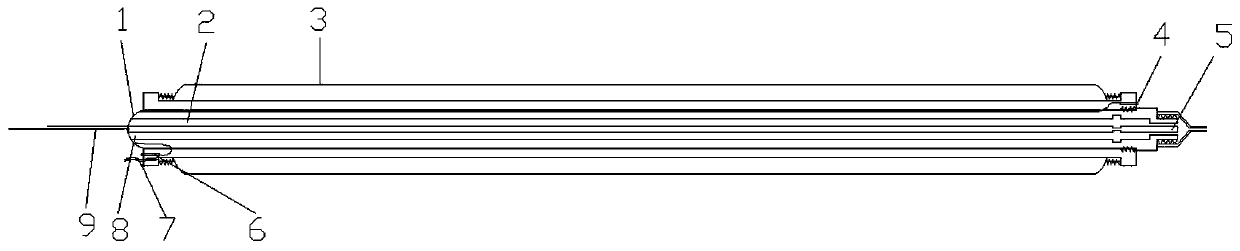

[0066] refer to figure 1 , this embodiment provides a polymer deep hole positioning self-sealing grouting nozzle, including: nozzle body,

[0067] The interior of the nozzle body is hollow, and a feeding pipe is provided in the hollow cavity, and the feeding pipe is used to transport the slurry; the discharge end of the nozzle body is provided with a nozzle, and the feeding pipe extends from the feeding end of the nozzle body into the interior of the nozzle body and It extends to the discharge end of the nozzle body and communicates with the nozzle;

[0068] As a preferred embodiment, two feeding pipes are arranged in the hollow cavity of the nozzle body of this embodiment: the first feeding pipe 2 and the second feeding pipe 8, and the nozzle is a mixing nozzle 5; the first feeding pipe 2 , the second feeding pipe 8 are respectively used to transport different slurries, the feeding ends of the two are respectively injected with different slurries through the grouting machine...

Embodiment 2

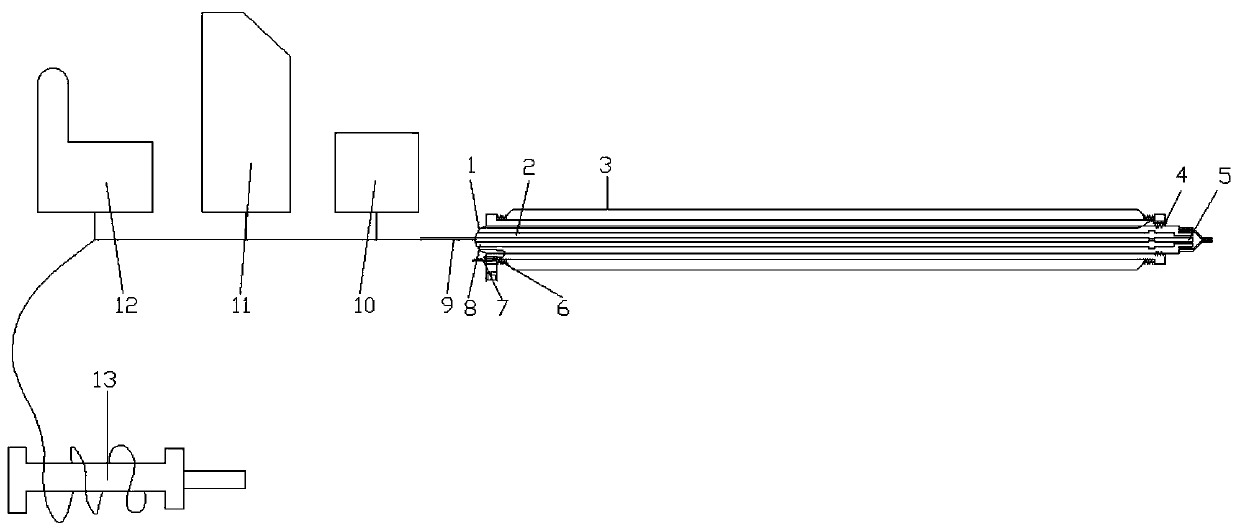

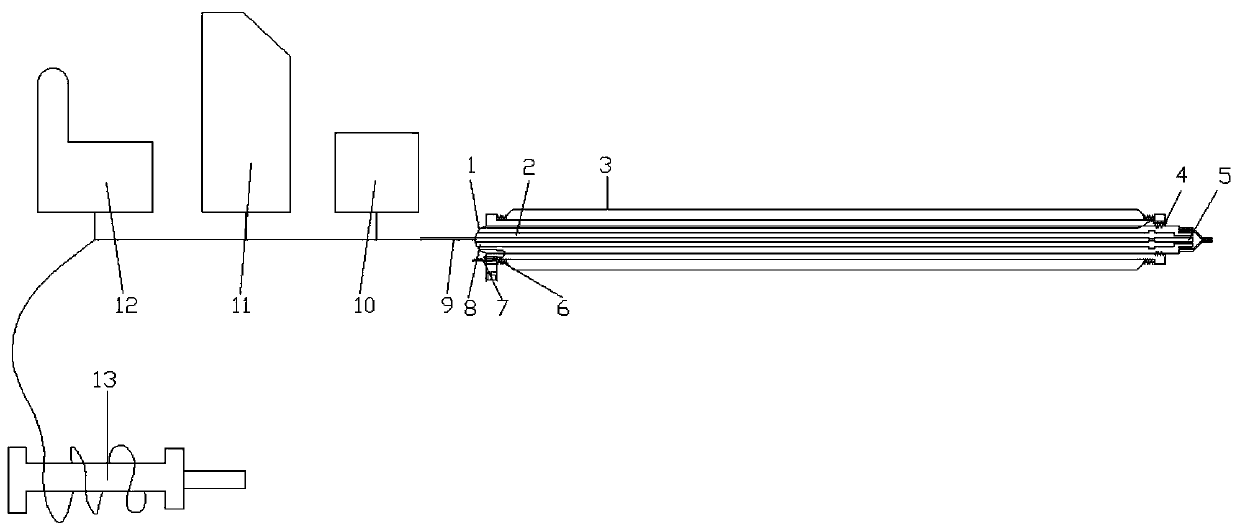

[0077] Such as figure 2 As shown, this embodiment provides a grouting system using the polymer deep hole positioning self-sealing grouting nozzle provided in Embodiment 1, including: the grouting nozzle provided in Embodiment 1, specifically including: the nozzle body,

[0078] The interior of the nozzle body is hollow, and a feeding pipe is provided in the hollow cavity, and the feeding pipe is used to transport the slurry; the discharge end of the nozzle body is provided with a nozzle, and the feeding pipe extends from the feeding end of the nozzle body into the interior of the nozzle body and It extends to the discharge end of the nozzle body and communicates with the nozzle;

[0079] As a preferred embodiment, two feeding pipes are arranged in the hollow cavity of the nozzle body of this embodiment: the first feeding pipe 2 and the second feeding pipe 8, and the nozzle is a mixing nozzle 5; the first feeding pipe 2 , the second feeding pipe 8 are respectively used to tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com