Long-distance pulverized coal conveying equipment

A long-distance, pulverized coal technology, used in conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as poor sealing performance of spiral gate valves, poor sealing effect of spiral gate valves, and inability to achieve design capabilities. Achieve the effect of small footprint, small investment and reduced motor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

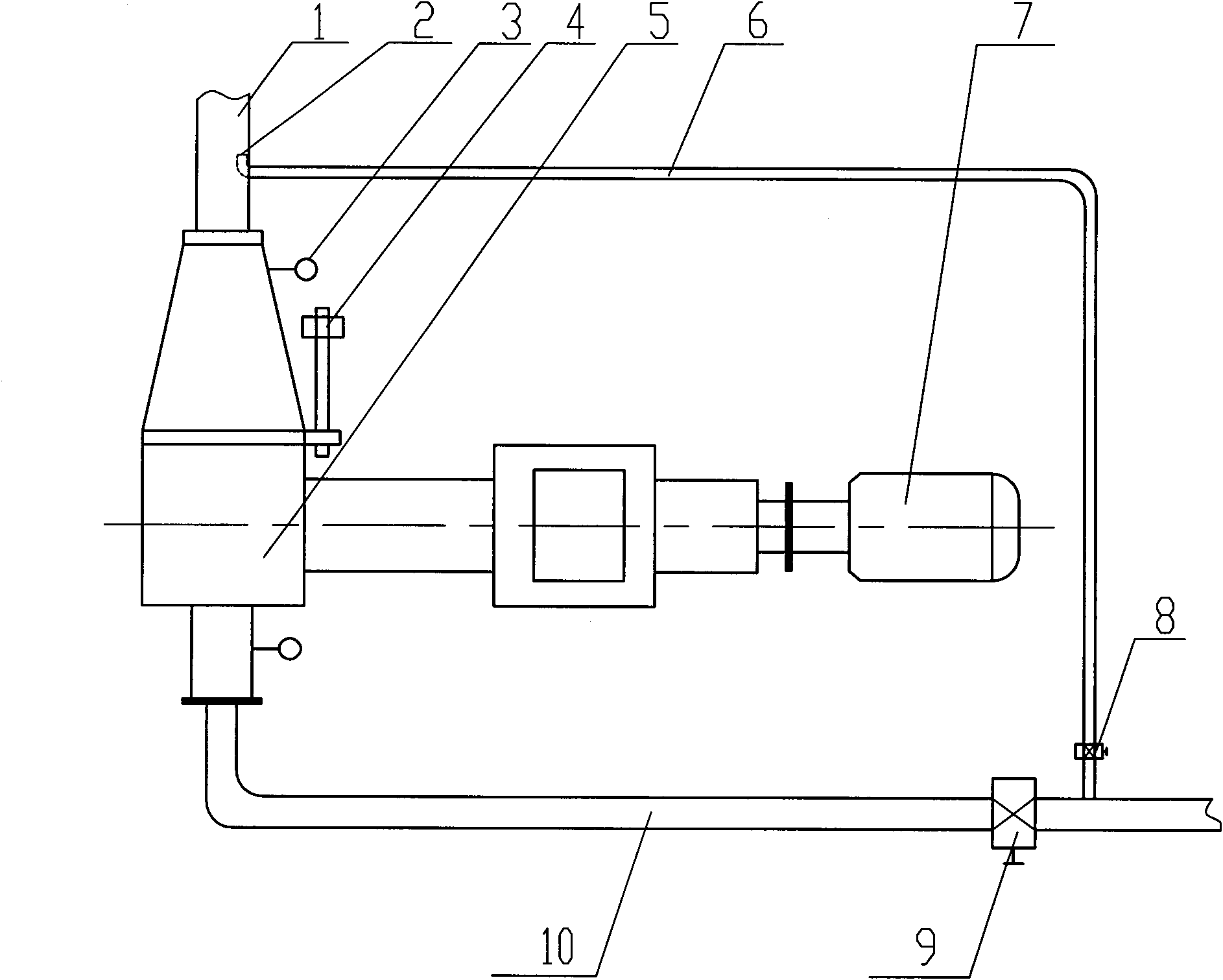

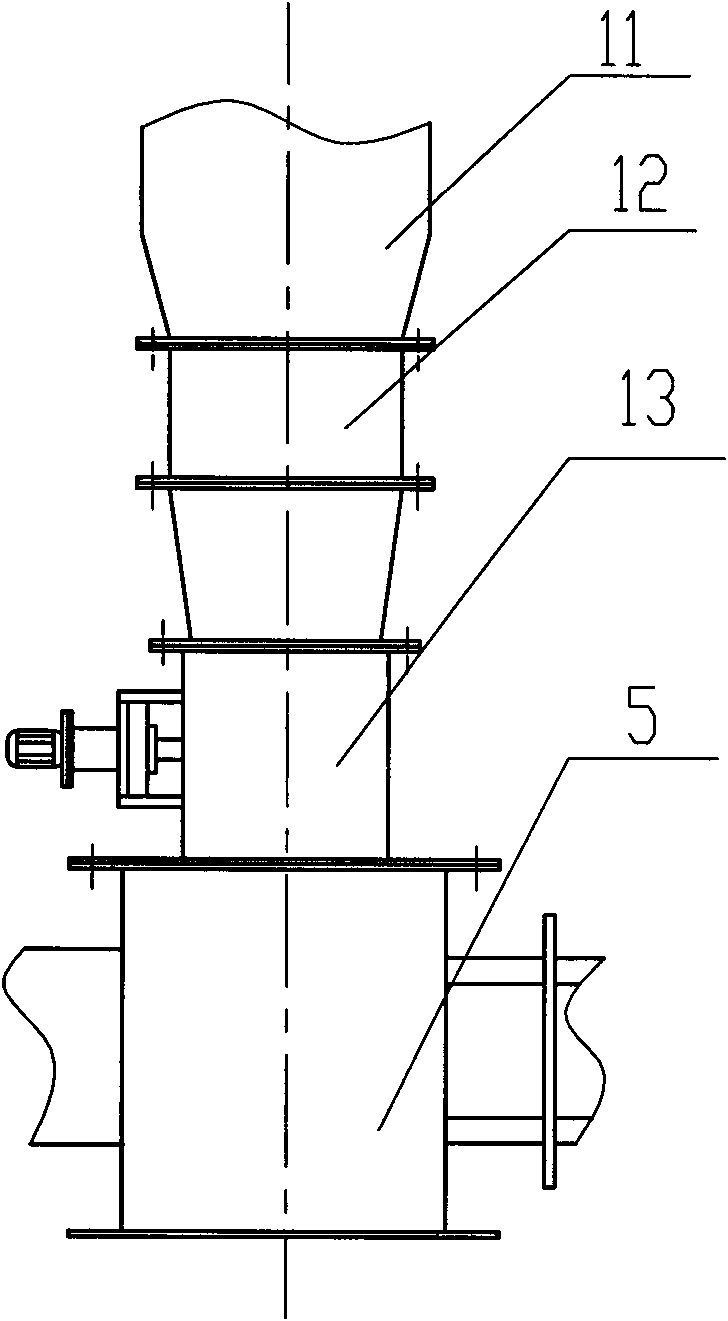

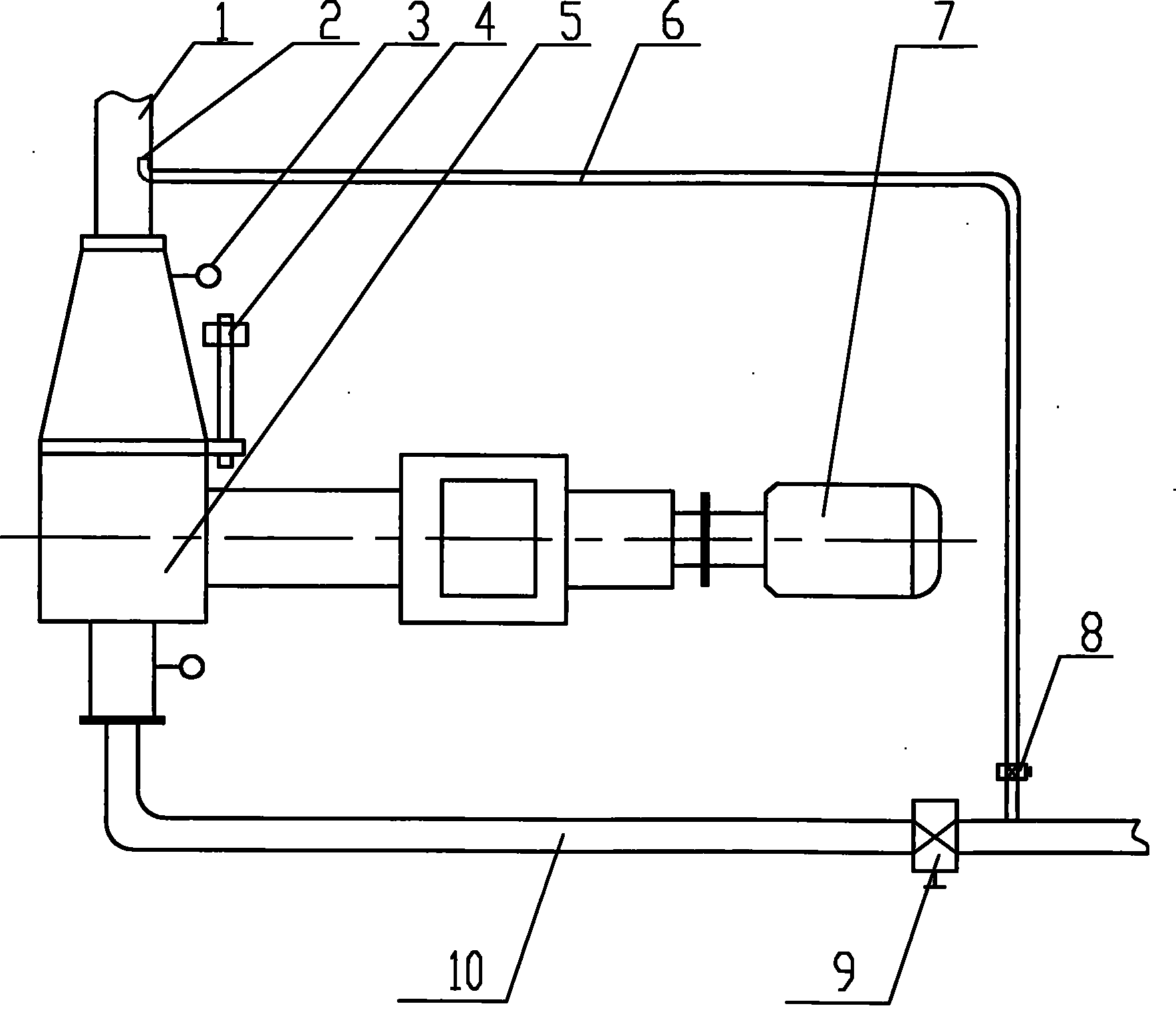

[0016] See attached figure 1 , the structure of the present invention includes a screw conveying pump 5 located at the bottom of the coal powder bin 11, the front end of the screw conveying pump 5 is connected with a pulverized coal conveying pipeline 1, and the rear end of the screw conveying pump 5 is connected with an air supply pipeline 10. An auxiliary air supply duct 6 is provided between the powder delivery duct 1 and the air supply duct 10 . The auxiliary air supply pipe 6 is connected to the pulverized coal conveying pipe 1 through the screw conveying pump. One end of the auxiliary air supply pipe 6 communicates with the air supply pipe 10 through a ball valve 8 or a stop valve, and the other end connects with the pulverized coal through the provided elbow 2. The delivery pipeline 1 communicates. Here, the elbow 2 is a 90-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com