Bearing constant-pressure pretightening device and selective assembly method thereof

A technology of constant pressure preload and bearing, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of light load slippage and wear, etc., and achieve the effect of convenient and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

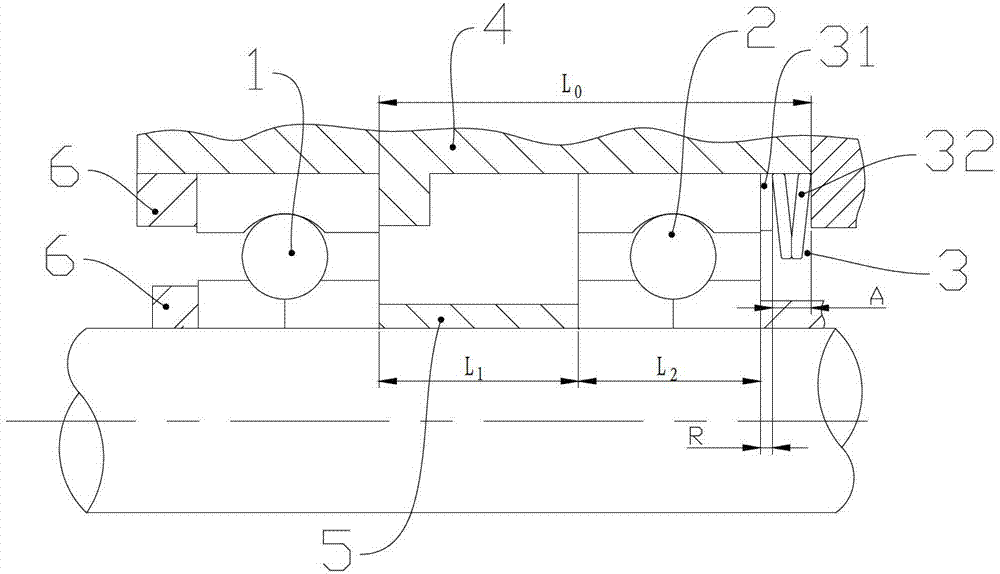

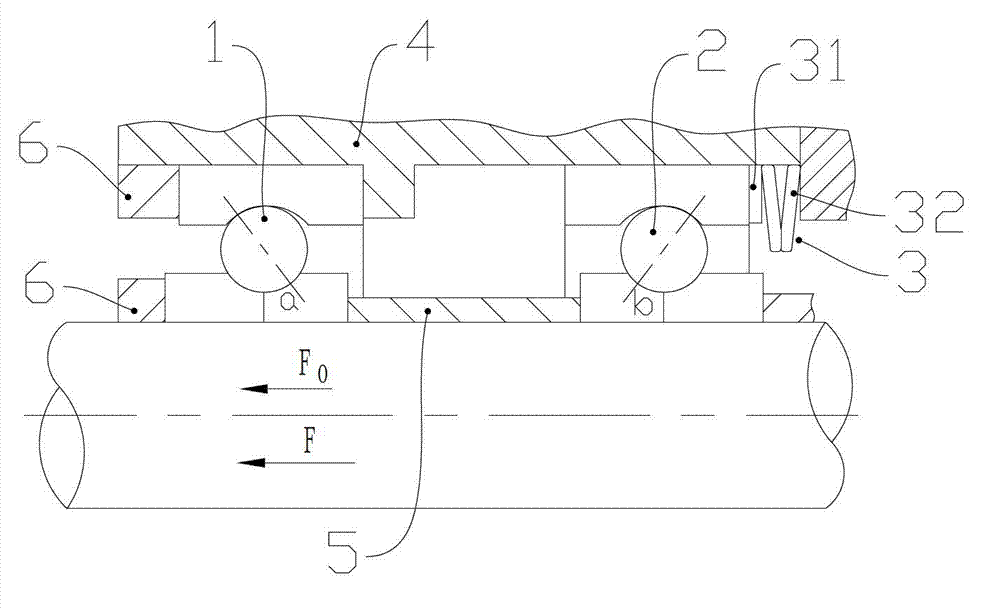

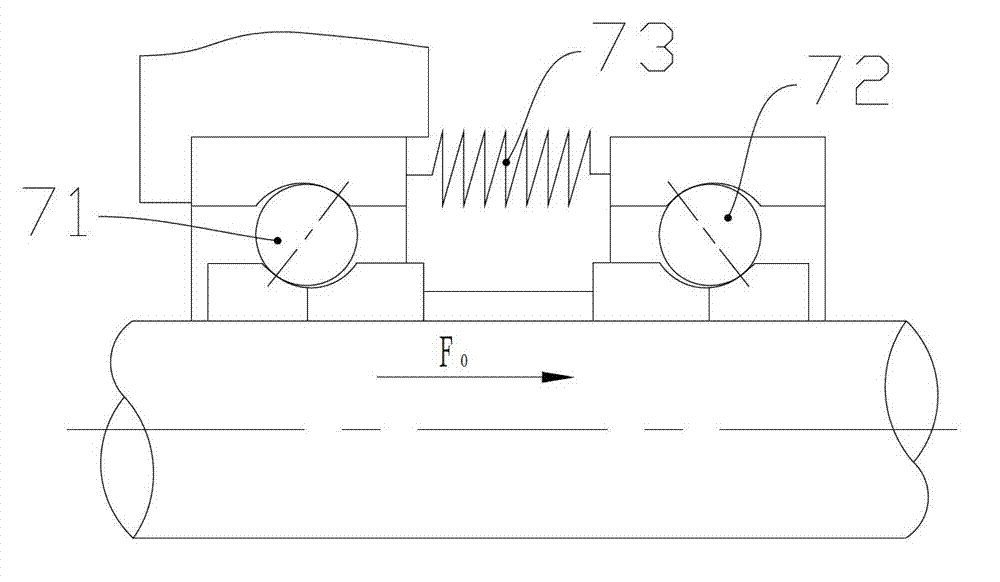

[0022] see figure 1 , the present invention provides a bearing constant pressure preloading device, which includes a fixed first bearing 1, a second bearing 2 that can be adjusted in the axial direction, and a first end that abuts against the outer ring of the second bearing 2. Preload component 3. Among them, the first bearing 1 is fixedly arranged between the rotating shaft and the stator 4 to bear the load; the second bearing 2 is arranged between the rotating shaft and the stator 4 and is adjustable in the axial direction; the preload assembly 3 is a compressible and stretchable elastic assembly , for bearing preload, and the preload F 0 It is transmitted to the second bearing 2 and the first bearing 1 in the form of deformation. Both the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com