Pneumatic box sealing machine

A kind of sealing machine, pneumatic technology, applied in the field of pneumatic sealing machine, can solve the problem of cost increase, achieve the effect of lower hardness requirement, high efficiency and short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The specific embodiments described are only used to explain the present invention and are not used to limit the specific embodiments of the present invention.

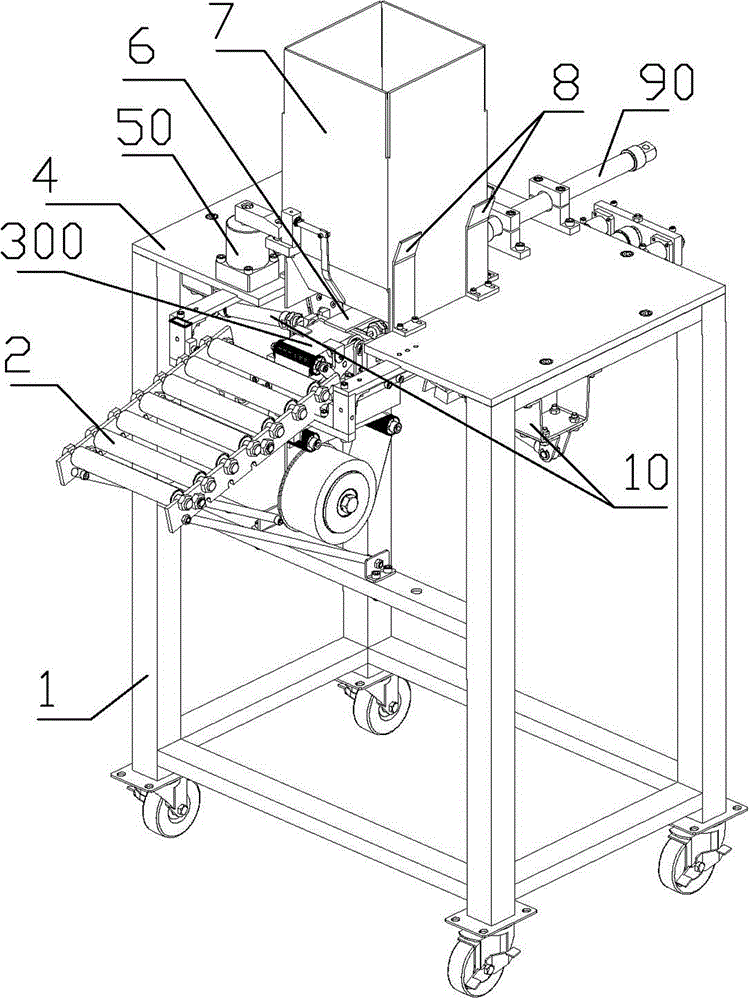

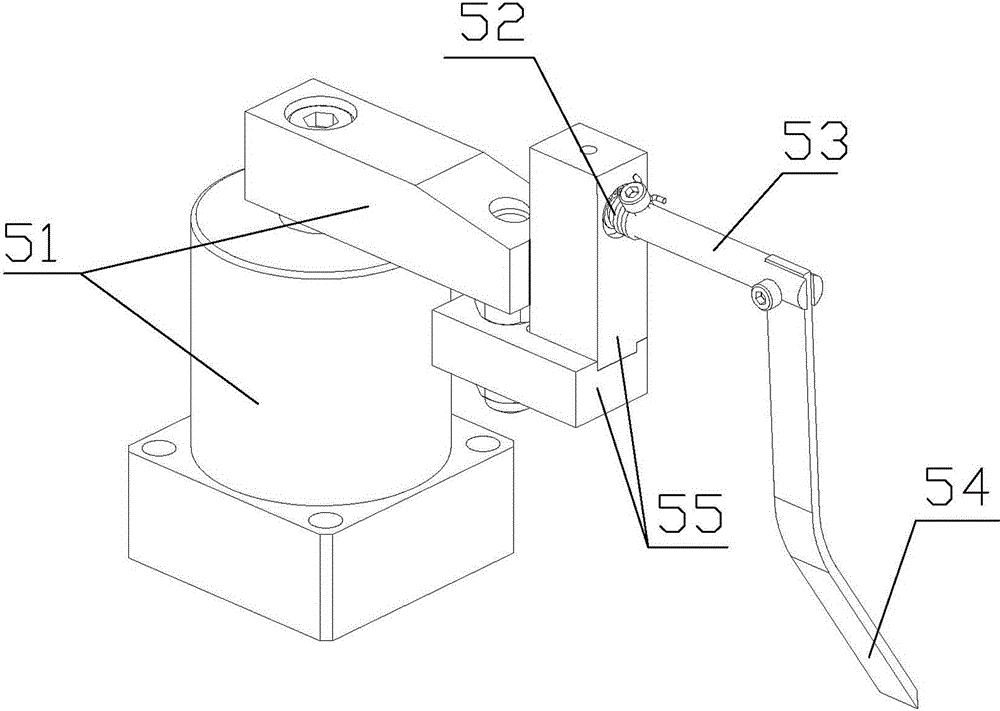

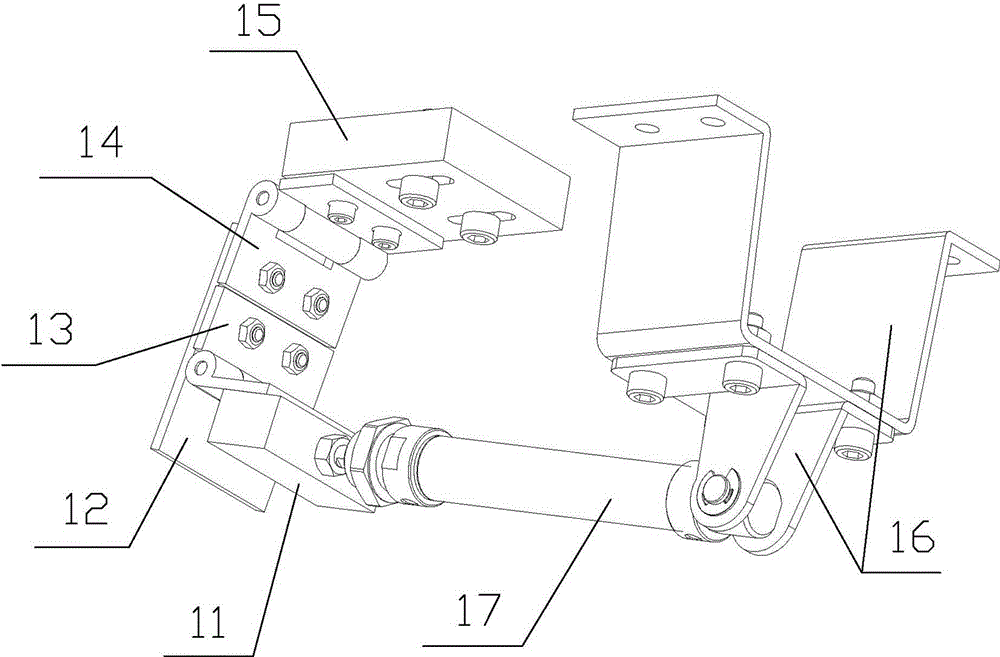

[0026] Pneumatic sealing machine, such as figure 1 As shown, including the workbench 4, the support frame 1, the out-carton roller bracket 2, and the carton inlet guide bar 8 arranged above the workbench, the rear lower cover folding guide mechanism (not shown), and the front lower cover The folding guide mechanism 50, the carton pushing mechanism 90, and the carton lower cover folding press block 6, the left lower cover folding device (not shown), the right lower cover folding device 10, and the pneumatic adhesive paper seal are arranged below the workbench. Box movement device 300.

[0027] The opening on one side of the workbench 4 is in the shape of a letter to form a box container and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com