Tobacco leaf extract and cocoa extract composite fermentation perfume preparation method and applications of tobacco leaf extract and cocoa extract composite fermentation perfume in recombinant tobacco leaf

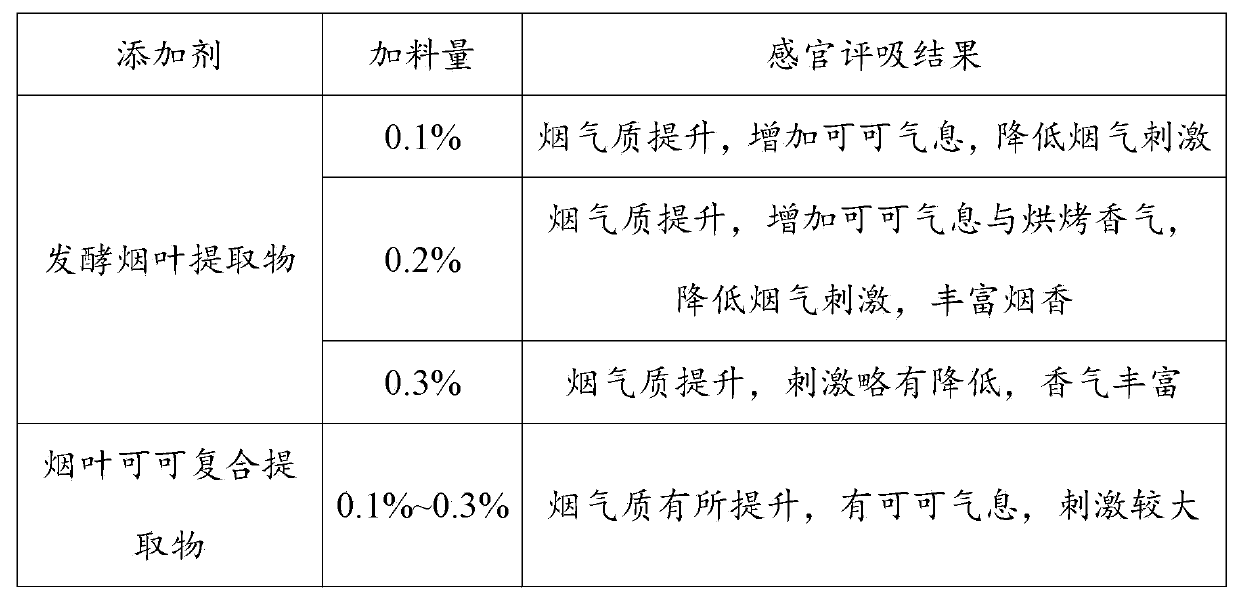

A compound fermentation and extraction technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, and tobacco preparation, can solve problems such as uncomfortable taste, strong irritation, and weak smoke, so as to reduce smoke irritation and improve The effect of stimulating and increasing the aroma of roasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

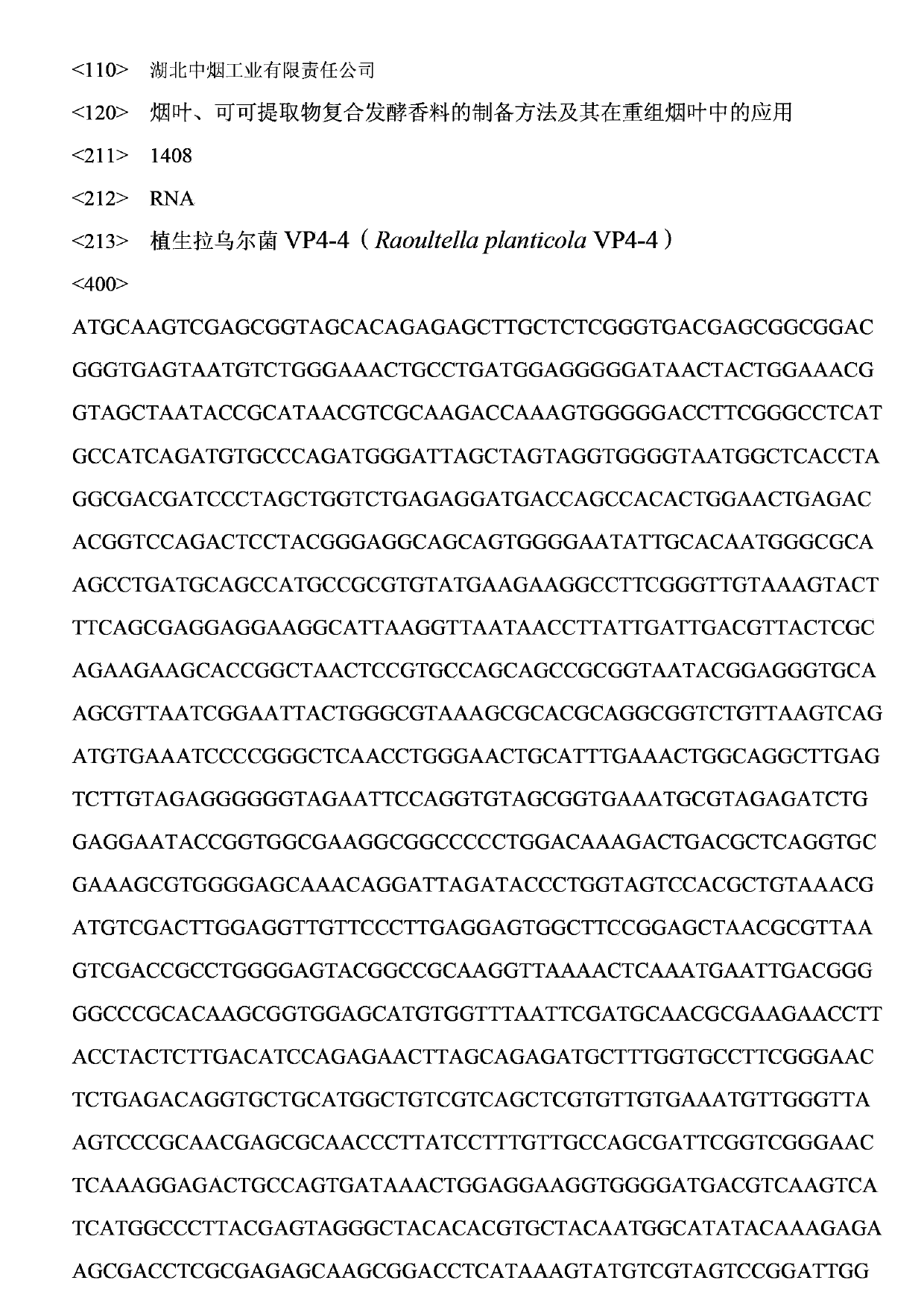

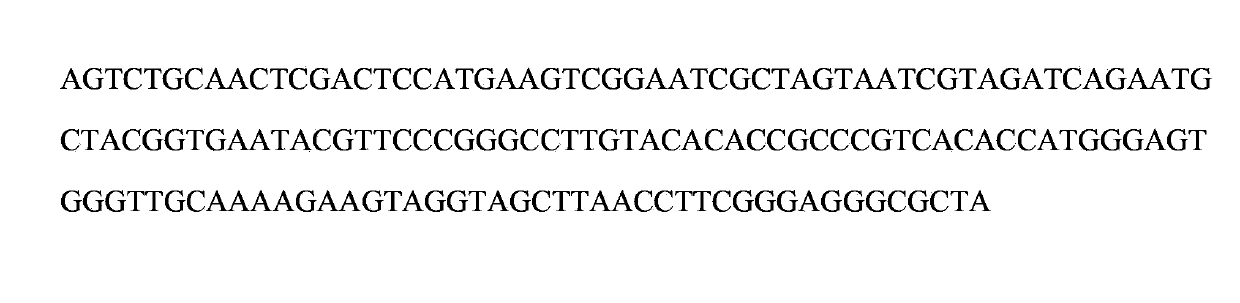

[0026] The preparation method of the microbial Raoultella planticolaVP4-4 CCTCC M 2012005 biotransformation of the present invention to produce tobacco leaves and cocoa extract compound fermentation spices is as follows:

[0027] 1) Crush the tobacco leaves to 80 mesh, then mix the tobacco powder and cocoa powder according to the mass ratio of 1:2, add water with a mass ratio of 1:30 to the mixture, reflux extraction for 3 hours and then filter, repeat the reflux extraction filtrate for 3 times, and combine the filtrates , to obtain the mixed extract of tobacco leaves and cocoa, and sterilize it;

[0028] 2) Activation of strains: Inoculate Raoultella planticola VP4-4 CCTCC M 2012005 on the slant medium, and culture at 25°C for 24 hours to obtain activated strains, and place them in a refrigerator at 4°C;

[0029] The slant culture medium is: maltose: 120mL, glucose: 20g / L, agar: 15g / L.

[0030] 3) Preparation of seed culture solution: Inoculate the slant culture obtained in ...

Embodiment 2

[0035] The preparation method of the microbial Raoultella planticolaVP4-4 CCTCC M 2012005 biotransformation of the present invention to produce tobacco leaves and cocoa extract compound fermentation spices is as follows:

[0036] 1) Crush the tobacco leaves to 100 mesh, then mix the tobacco powder and cocoa powder in a mass ratio of 1:0.5, add water with a mass ratio of 1:50 to the mixture, reflux for extraction for 1 hour and then filter, repeat the reflux for 3 times to extract the filtrate, and combine the filtrate , to obtain the mixed extract of tobacco leaves and cocoa, and sterilize it;

[0037] 2) Activation of strains: Inoculate Raoultella planticola VP4-4 CCTCC M 2012005 on the slant medium, and culture at 38°C for 72 hours to obtain activated strains, and place them in a refrigerator at 4°C;

[0038] The slant culture medium is: maltose: 120mL, glucose: 20g / L, agar: 15g / L.

[0039] 3) Preparation of seed culture solution: Inoculate the slant culture obtained in ste...

Embodiment 3

[0044] The preparation method of the microbial Raoultella planticolaVP4-4 CCTCC M 2012005 biotransformation of the present invention to produce tobacco leaves and cocoa extract compound fermentation spices is as follows:

[0045] 1) Crush the tobacco leaves to 90 mesh, then mix the tobacco powder and cocoa powder in a mass ratio of 1:1, add water with a mass ratio of 1:40 to the mixture, reflux for extraction for 2 hours and then filter, repeat the reflux for 3 times to extract the filtrate, and combine the filtrate , to obtain the mixed extract of tobacco leaves and cocoa, and sterilize it;

[0046] 2) Strain activation: Inoculate Raoultella planticola VP4-4 CCTCC M 2012005 on the slant medium, and culture at 28°C for 72 hours to obtain the activated strain, and place it in a refrigerator at 4°C;

[0047] The slant culture medium is: maltose: 120mL, glucose: 20g / L, agar: 15g / L.

[0048] 3) Preparation of seed culture solution: Inoculate the slant culture obtained in step 2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com