A preparation method of cocoa black powder tobacco additive and its application in recombined tobacco leaf cigarettes

A technology for recombining tobacco leaves and cocoa black powder enzyme is applied in the preparation of additives for cocoa black powder tobacco, the preparation of additives for cocoa black powder tobacco, and the application field in reconstituted tobacco leaf cigarettes, which can solve the problem of affecting the pure smell of cigarette smoke and producing more The problems such as woody gas, pungent and spicy feeling, etc., achieve the effect of large-scale industrial application transformation prospects, rich aroma, and high content of aroma-enhancing components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

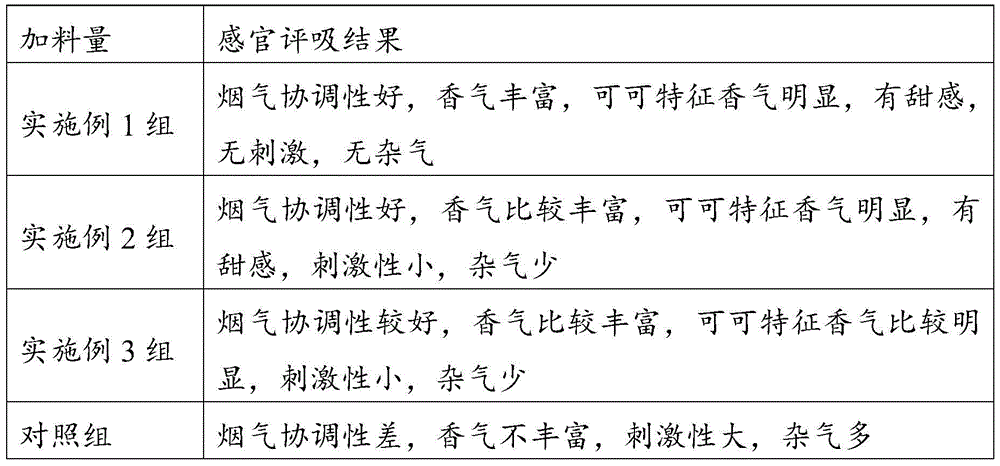

Examples

Embodiment 1

[0023] A preparation method of an additive for cocoa black powder tobacco, the steps are as follows:

[0024] 1) Add 3g of biological compound enzyme to 1Kg of natural cocoa black powder, stir and incubate in 15Kg of water with a pH of 10 and a temperature of 50°C for 8 hours, centrifuge at 9000rpm, and take the supernatant, which is the cocoa black powder enzyme fermentation liquid;

[0025] 2) Add 20 g of honey to the cocoa black powder enzyme fermentation liquid, mix well, stir, adjust the pH to 10, heat and reflux to carry out the Maillard reaction for 5 hours, after the reaction, concentrate the reaction liquid to a black dip with a relative density of 1.15 Paste to obtain cocoa black powder smoke additive.

[0026] Described biological complex enzyme is alkaline protease, alkaline cellulase, alkaline pectinase and alkaline amylase, the alkaline protease, alkaline cellulase, alkaline pectinase and alkaline amylase The weight ratio is =1:1:0.5:1.

Embodiment 2

[0028] A preparation method of an additive for cocoa black powder tobacco, the steps are as follows:

[0029] 1) Add 5g of biological compound enzyme to 1Kg of natural cocoa black powder, stir and incubate in 20Kg of water with a pH of 8 and a temperature of 60°C for 4 hours, centrifuge at 10000rpm, and take the supernatant, which is the cocoa black powder enzyme fermentation liquid;

[0030] 2) Add 50 g of honey to the cocoa black powder enzyme fermentation liquid, mix well, stir, adjust the pH to 11, heat and reflux to carry out Maillard reaction for 8 hours, after the reaction is over, concentrate the reaction liquid to a black dip with a relative density of 1.1 Paste to obtain cocoa black powder smoke additive.

[0031] Described biological complex enzyme is alkaline protease, alkaline cellulase, alkaline pectinase and alkaline amylase, the alkaline protease, alkaline cellulase, alkaline pectinase and alkaline amylase The weight ratio is = 1:2:2:2.

Embodiment 3

[0033] A preparation method of an additive for cocoa black powder tobacco, the steps are as follows:

[0034] 1) Add 1g of biological compound enzyme to 1Kg of natural cocoa black powder, stir and incubate in 8Kg of water with a pH of 11 and a temperature of 40°C for 24 hours, centrifuge at 8000rpm, and take the supernatant, which is the cocoa black powder enzyme fermentation liquid;

[0035] 2) Add 50 g of honey to the cocoa black powder enzyme fermentation liquid, mix well, stir, adjust the pH to 9, heat and reflux for Maillard reaction for 3 hours, after the reaction is over, concentrate the reaction liquid to a black leaching liquid with a relative density of 1.2 Paste to obtain cocoa black powder smoke additive.

[0036] Described biological complex enzyme is alkaline protease, alkaline cellulase, alkaline pectinase and alkaline amylase, the alkaline protease, alkaline cellulase, alkaline pectinase and alkaline amylase The weight ratio is =1:0.5:0.5:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com