Two-for-one twisting false twisting yarn channel by two-side rounding type coaxial double-overfeeding one-step method

A false-twisted yarn and coaxial technology, which is applied in the field of double-sided winding coaxial double-overfeed single-step double-twisted false-twisted yarns, can solve problems such as being unfavorable for mechanically aided design and actual operation, and complex yarn routing. , to achieve the effect of simple structure, low cost and simplified transmission mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

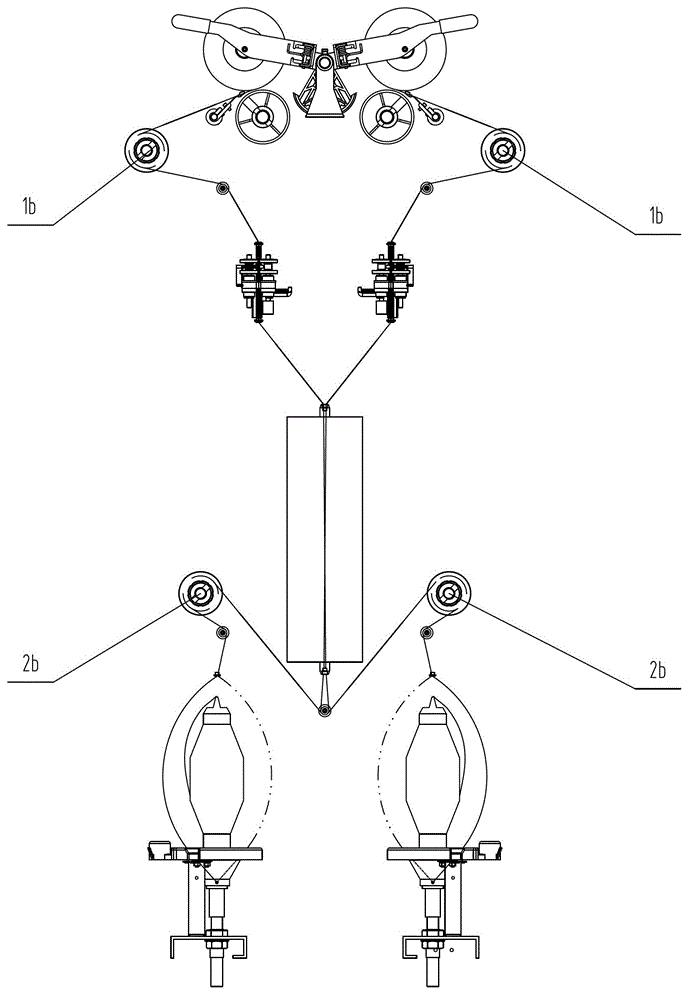

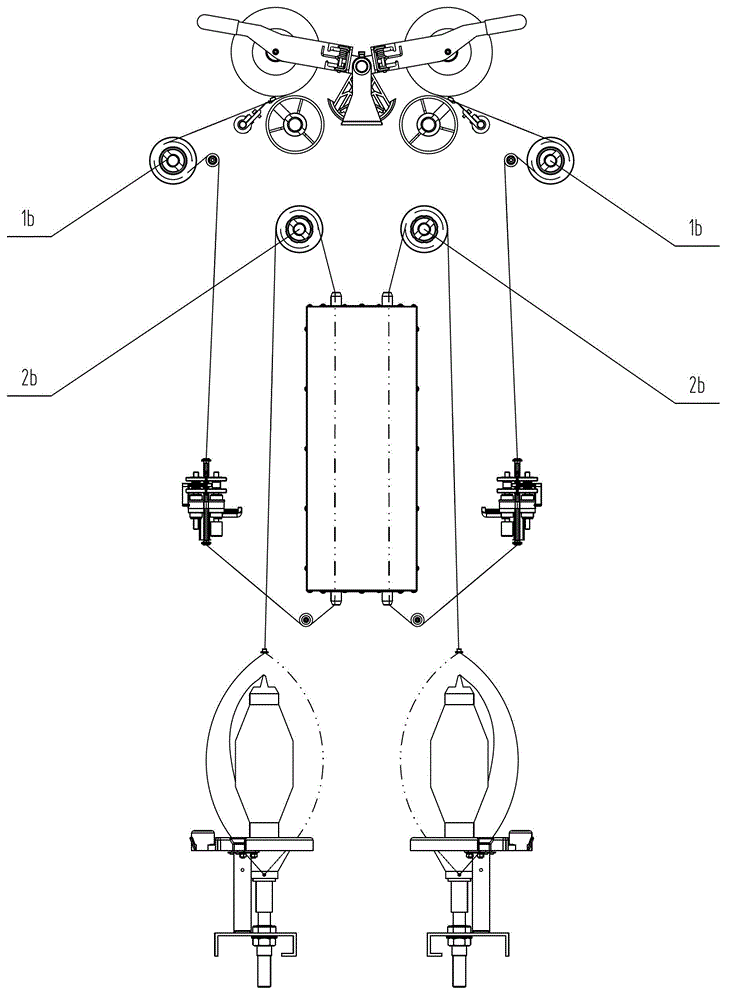

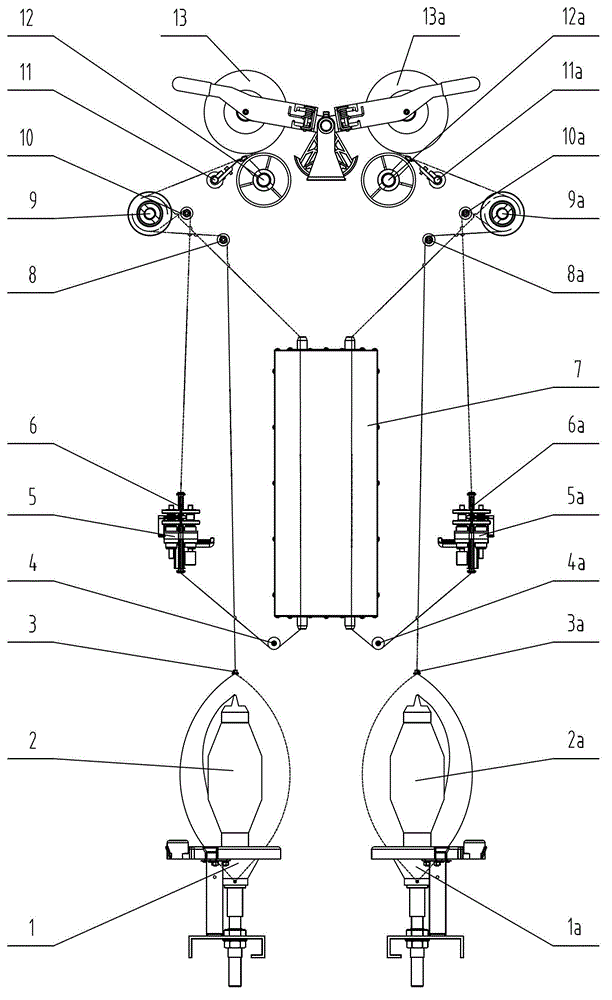

[0019] The present invention will be further described below in conjunction with specific drawings.

[0020] Such as Figure 3~Figure 5 As shown: the double-sided winding coaxial double overfeed one-step two-for-one twisting and false-twisting thread path includes left two-for-one twisting spindle 1, right two-for-one twisting spindle 1a, left spindle 2, right spindle 2a, and left picker rod porcelain eye 3. Porcelain eye 3a of the right screw rod, the first left thread passing roller 4, the first right thread passing roller 4a, the left false twister 5, the right false twister 5a, the left rotor 6, the right rotor 6a, the heating box 7. The second left wire passing roller 8, the second right wire passing roller 8a, the left double overfeed roller 9, the right double overfeed roller 9a, the third left wire passing roller 10, the third right wire passing roller 10a, move left Silk spinning head 11, right moving silk spinning head 11a, left transmission friction wheel 12, right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com