Safety baffle for road construction

A technology for safety baffles and road construction, applied to fences, building types, buildings, etc., can solve problems such as unsafe safety baffles, hidden dangers to the personal safety of road construction personnel, and no sound-absorbing effect, so as to achieve the effect of protecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

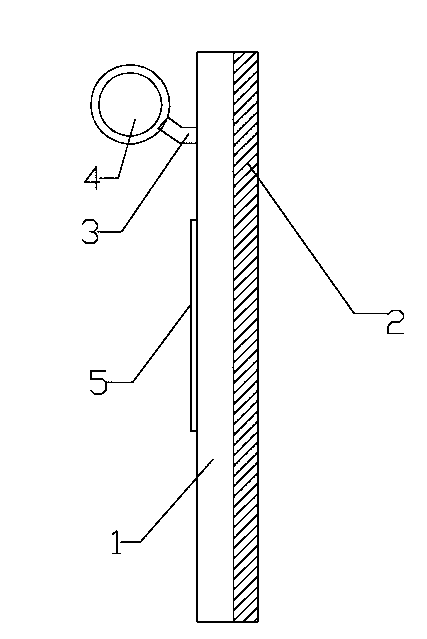

[0012] like figure 1 As shown, the road construction safety baffle includes a baffle body 1, a sound-absorbing layer 2, a reflective tape 5 and a sight glass. The sound-absorbing layer 2 is provided on one side of the baffle body 1, and the reflective tape 5 and a sight glass are provided on the other side. The sight glass includes a mirror surface 4 and a mirror frame 3 , and the mirror surface 4 is connected with the baffle body 1 through the mirror frame 3 . A sight glass is arranged on the baffle body 1, so that the construction personnel can clearly see the road conditions on the other side of the baffle before entering and exiting the baffle, which protects the personal safety of the construction personnel to the greatest extent.

[0013] The sound-absorbing layer 2 is provided on the baffle body 1, which has a certain sound-absorbing effect, so that during road cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com