Apparatus and method for measuring gas phase saturation degree of single tube core during foam flooding process

A working method, technology of foam generating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

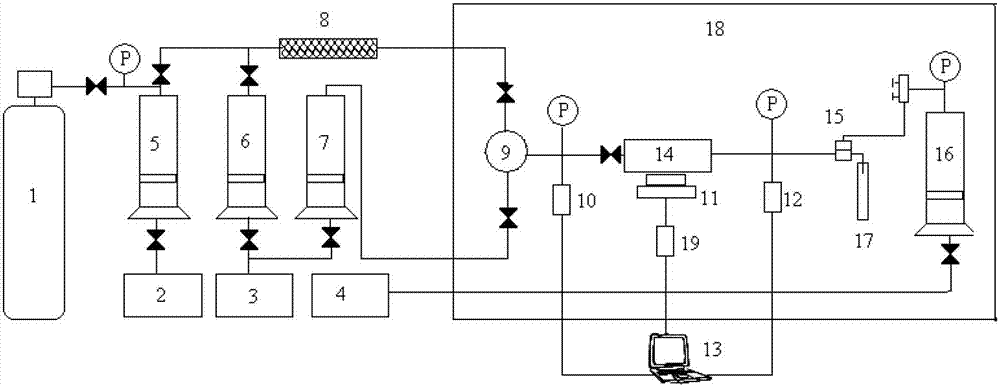

[0041] Such as figure 1 shown.

[0042] A device for measuring the gas phase saturation of single-pipe core foam flooding, including a foam generating device, an intermediate container 7 for holding formation water, a constant temperature box 18, a core tube 14 and a data acquisition system; the core tube 14 is installed in the In the constant temperature box 18; the foam generating device and the intermediate container 7 containing the formation water are respectively connected to the entrance of the core pipe 14 through the three-way valve 9; the data acquisition system includes pressure sensors connected to the computer 13 respectively 10. Pressure sensor 12 and load cell 19, the pressure sensor 10 is installed at the entrance of the core tube 14, the pressure sensor 12 is installed at the outlet of the core tube 14, and the load cell 19 is installed at the The bottom of the core tube 14; the pressure sensors 10 and 12 are used to monitor the differential pressure at both ...

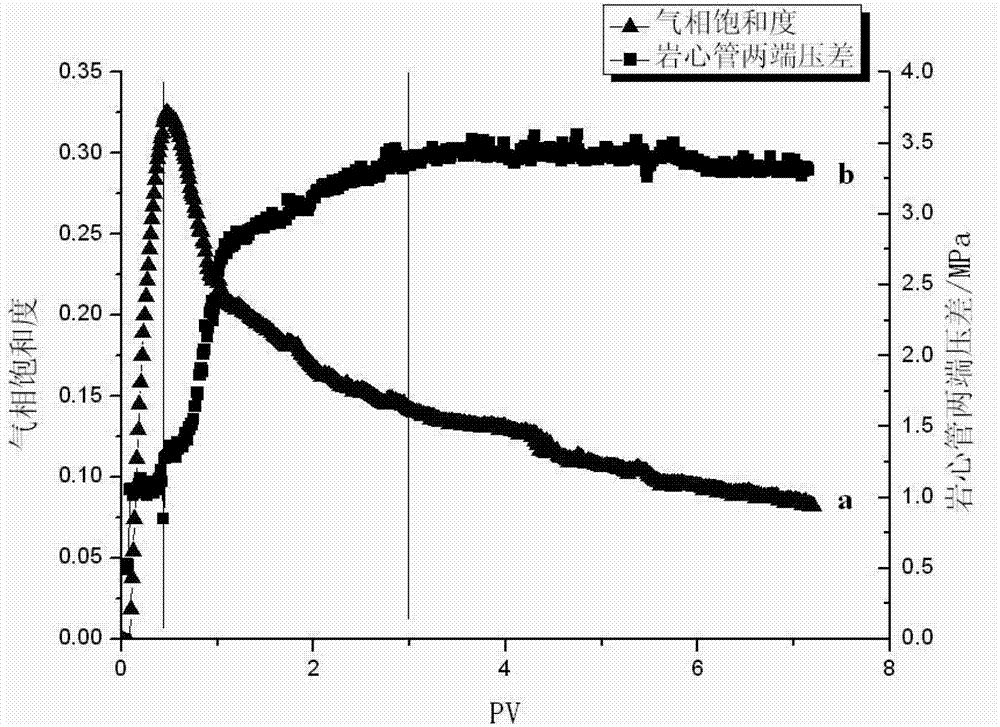

Embodiment 2

[0046] Required conditions for the method of measuring the gas phase saturation of single-tube core foam drive: i ignore the mass of gas in the core tube 14; ii the density of the foaming agent solution is equal to the density of formation water.

[0047] A method utilizing the device described in Example 1 to measure the saturation of the single-pipe core foam flooding gas phase, comprising the following steps:

[0048] (1) Simulate the formation conditions of the oilfield: fill the core tube 14 with quartz sand according to the experimental ratio;

[0049] (2) Measure the permeability of the core tube 14 with a gas permeability meter, and weigh the dry weight of the core tube 14 after sand filling in m 0 :

[0050] The proportion of quartz sand used in this embodiment is by mass: 100-120 mesh quartz sand: 10-20 parts; 160-180 mesh quartz sand: 80-90 parts. The permeability of the core pipe 14 at the filled place is 234×10 -3 μm 2 , the dry weight of the core tube 14 m 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com