Manufacturing method of alignment film

A production method and alignment film technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as inability to achieve wide viewing angles, fine dust generated by alignment layers, difficulty in large-sized panels, etc., and achieve the best process yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

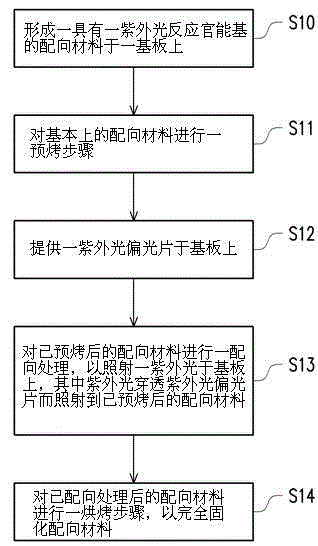

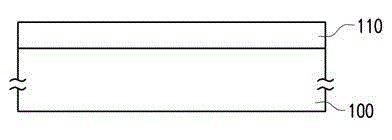

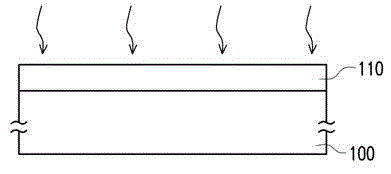

[0024] figure 1 Shown is a schematic flow chart of a method for fabricating an alignment film according to an embodiment of the present invention. Figure 2A to Figure 2E shown as figure 1 A schematic cross-sectional view of the fabrication method of the alignment film. Please also refer to figure 1 and Figure 2A , in this embodiment, an alignment material 110 having an ultraviolet light reactive functional group is formed on a substrate 100 . The material of the alignment material 110 in this embodiment is, for example, a polymer material with photoreactive functional groups, such as polyimide or polyamic acid, and the substrate 100 is, for example, a color filter substrate or an active device array substrate.

[0025] It should be noted that, before forming the alignment material 110 on the substrate 100, the substrate 100 may be cleaned first. In addition to increasing the bondability between the alignment material 110 and the substrate 100, it can also effectively im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com