Motor stator with deformable iron core and manufacturing method thereof

A motor stator and iron core technology, which is applied in the field of motor stator preparation, can solve the problems of reduced motor efficiency, low full rate of wire slots, low production efficiency, etc., and achieves the effect of ensuring the full rate of slots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A specific embodiment of a motor stator provided with a deformable iron core of the present invention will now be described with reference to the accompanying drawings.

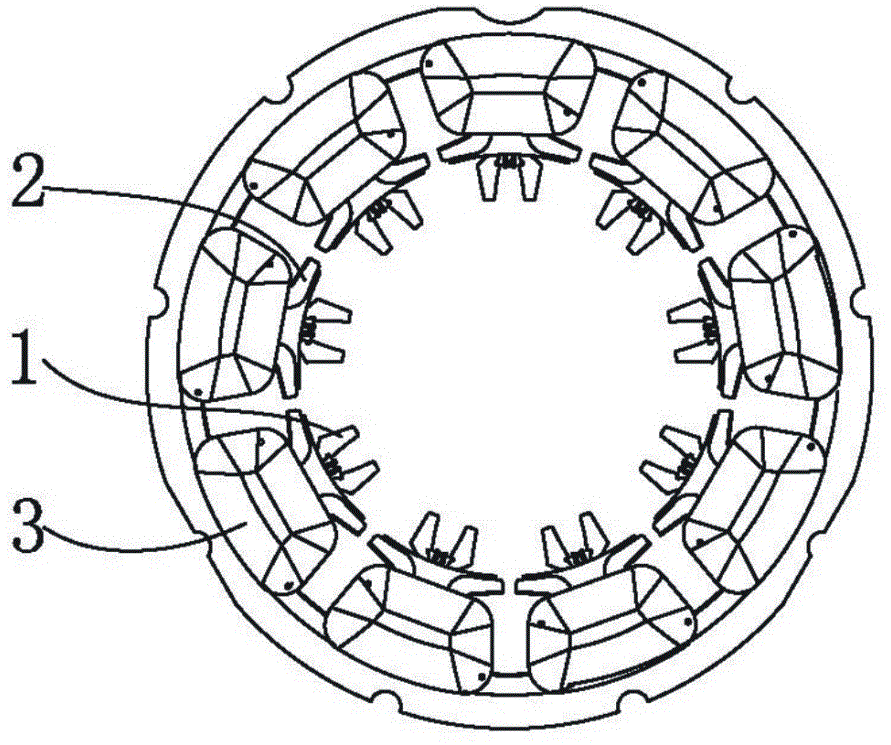

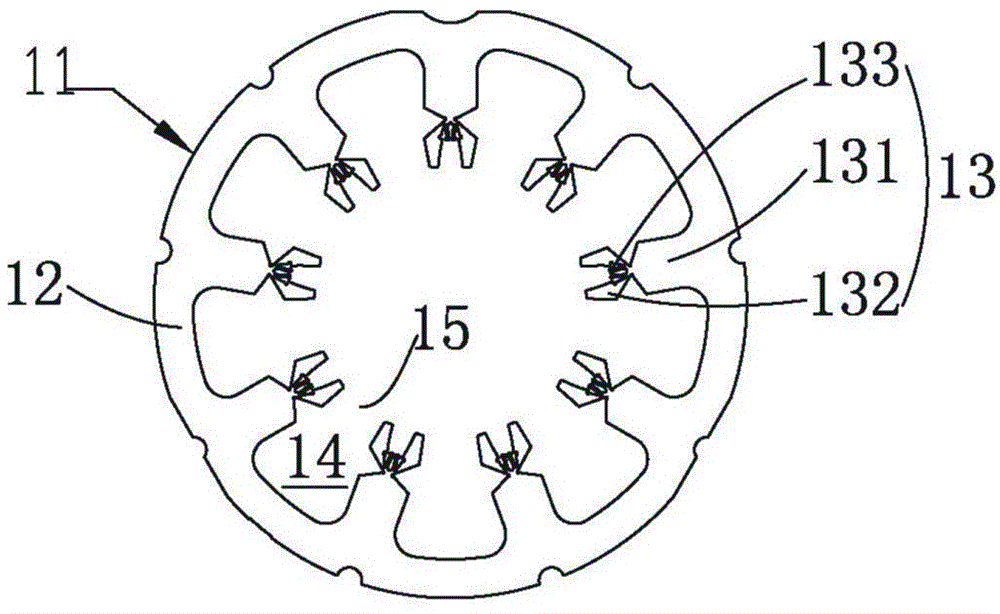

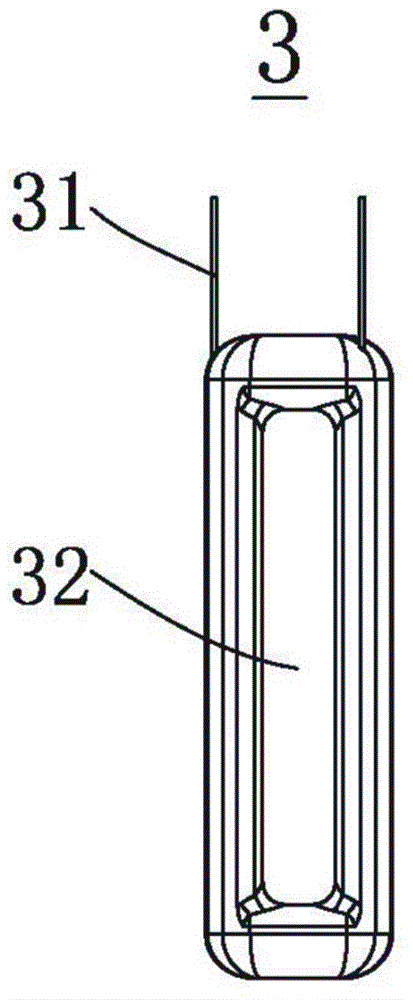

[0035] see Figure 1 to Figure 4 As shown, Embodiment 1 of the present invention, a motor stator provided with a deformable core of the present invention includes a stator core 1, a coil 3 and an insulating component 2, and the stator core 1 is formed by stacking a plurality of one-piece stator chips 11 The stator core 11 is made of magnetically conductive material, the stator core 11 includes a magnetically conductive ring 12, a Y-shaped magnetic pole 13 that protrudes inward along the inner side of the magnetically conductive ring 12 and is uniformly distributed in the axial direction, and two magnetic poles of the Y-shaped magnetic pole 13 The wings 132 can be expanded to both sides, and a wire groove 14 is formed between two adjacent magnetic poles 13 and the inner surface of the magnetic conductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com