Stator block coil shaping device

A technology for shaping devices and stators, which is applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of large surface damage of enameled wires, easy damage to plastics, and low efficiency, so as to ensure slot fullness and facilitate connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below according to the accompanying drawings and specific embodiments.

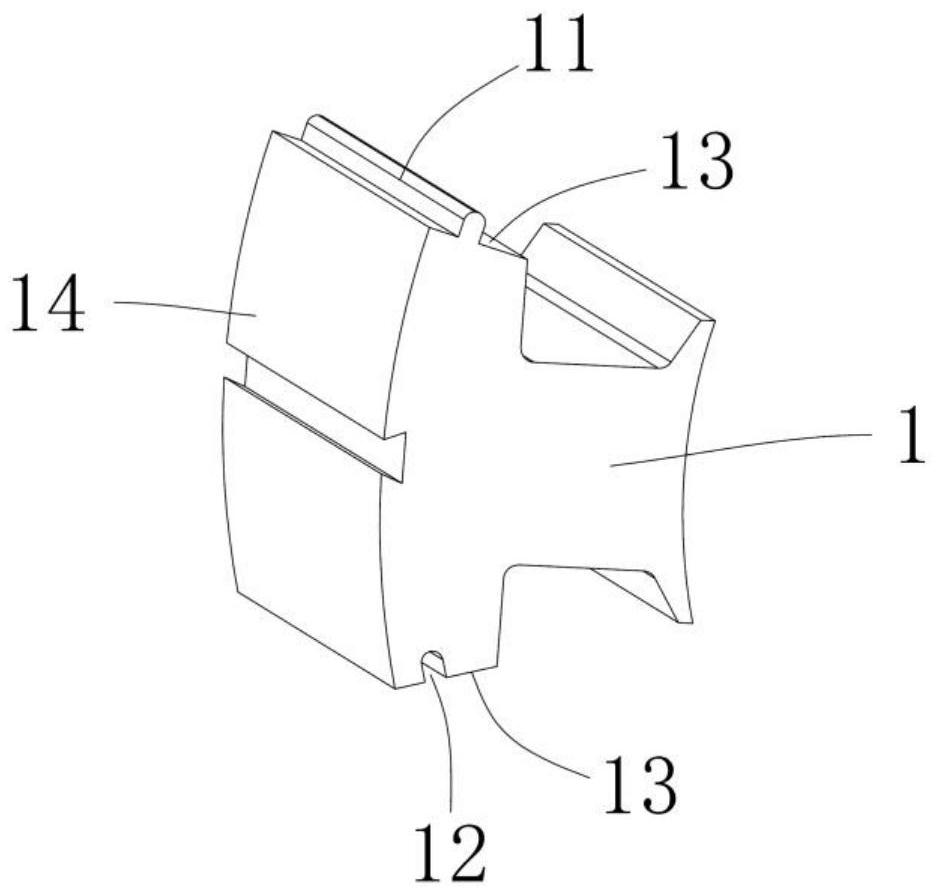

[0025] The device of the present invention is used for figure 1 As shown in the shaping of the stator block 1, the opposite sides of the stator block 1 are respectively provided with a connection structure for connecting and fixing two adjacent stator blocks. The connection structure includes a protrusion 11 and a matching groove 12. The opposite sides of the stator block 1 Each has a side surface 13 , and the radial outer end surface of the stator block is an arc surface 14 .

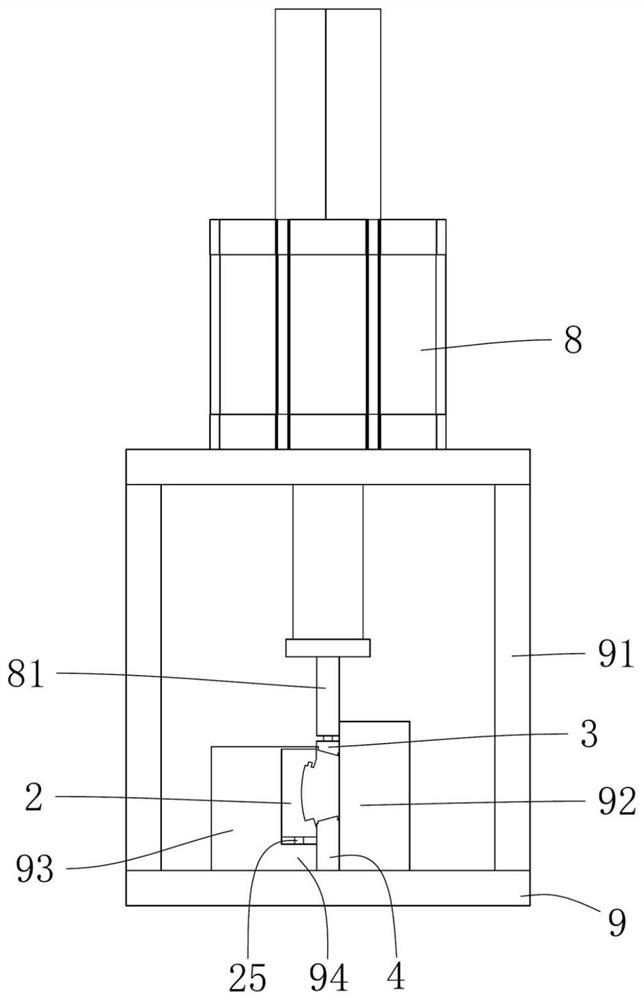

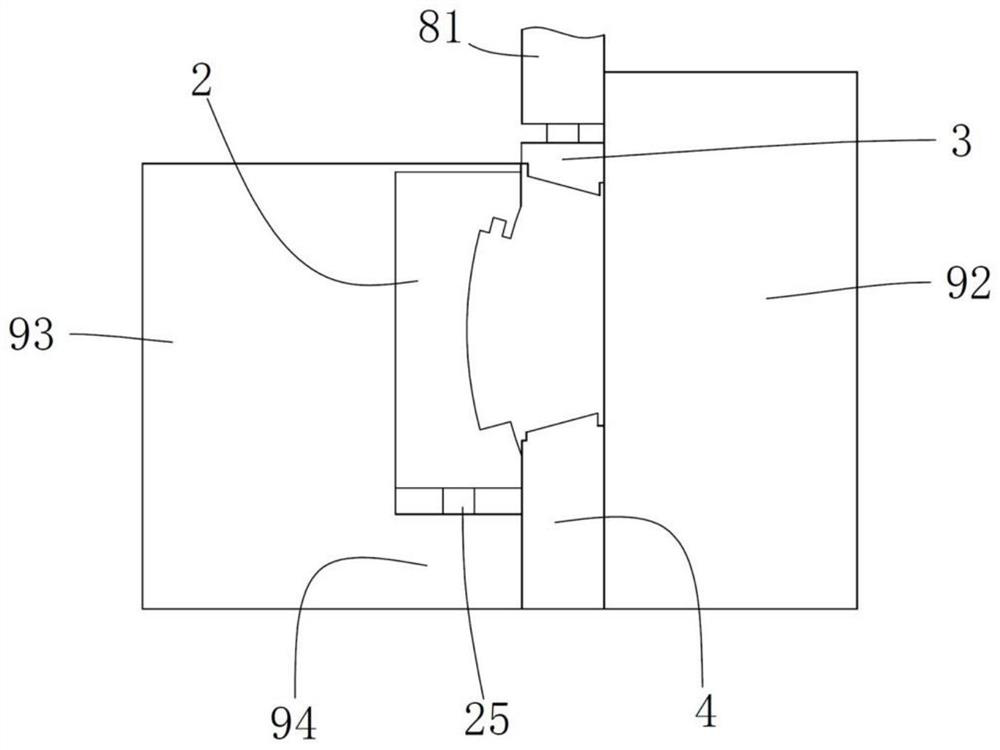

[0026] Depend on Figure 2 to Figure 5 As shown in the figure, the present embodiment discloses a coil shaping device for stator segments, including a positioning block 2, a movable shaping block 3 and a fixed shaping block 4. The fixed shaping block 4 is supported and fixed on the upper side of the base plate 9, and the base plate 9 is also provided with The bracket 91, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com