Brushless Hall externally built direct current motor

A technology of DC motors and motor shafts, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of inconvenient dismantling and repair of the motor Hall, and achieve the effects of reducing the probability of burning out, prolonging the service life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

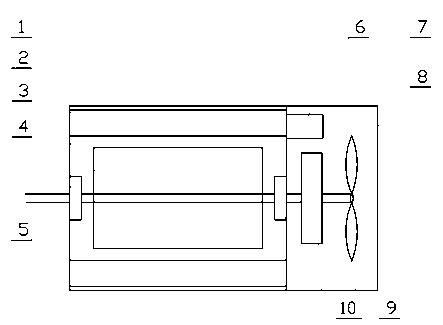

[0009] exist figure 1 Among them, the brushless Hall external DC motor includes a casing 1, a stator 2, an inner rotor 3, a bearing I 4, a motor shaft 5, a Hall element 6, a rear cover 7, an air impeller 8, an outer rotor 9, and a bearing II 10 , the motor shaft 5 fixes the inner rotor 3 in the space surrounded by the stator 2 through the bearing I 4 and the bearing II 10, an outer rotor 9 is arranged on the motor shaft 5 outside the stator 2, and a Hall element is correspondingly installed above the outer rotor 9 6. One end of the motor shaft 5 outside the casing 1 is connected to the wind impeller 8, and the outside of the Hall element 6, the outer rotor 9 and the wind impeller 8 is connected to a rear cover 7, and the rear cover 7 plays a role of protecting internal components. When in use, because the Hall element 6 is placed outside, the heat is reduced, reducing the frequency of the Hall element 6 being burned out, and when dismantling and repairing, only need to open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com