Shot treatment device

A technology of shot peening treatment and tools, which is applied in the field of shot peening treatment devices, can solve the problems such as the decrease of projection efficiency, and achieve the effect of improving projection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

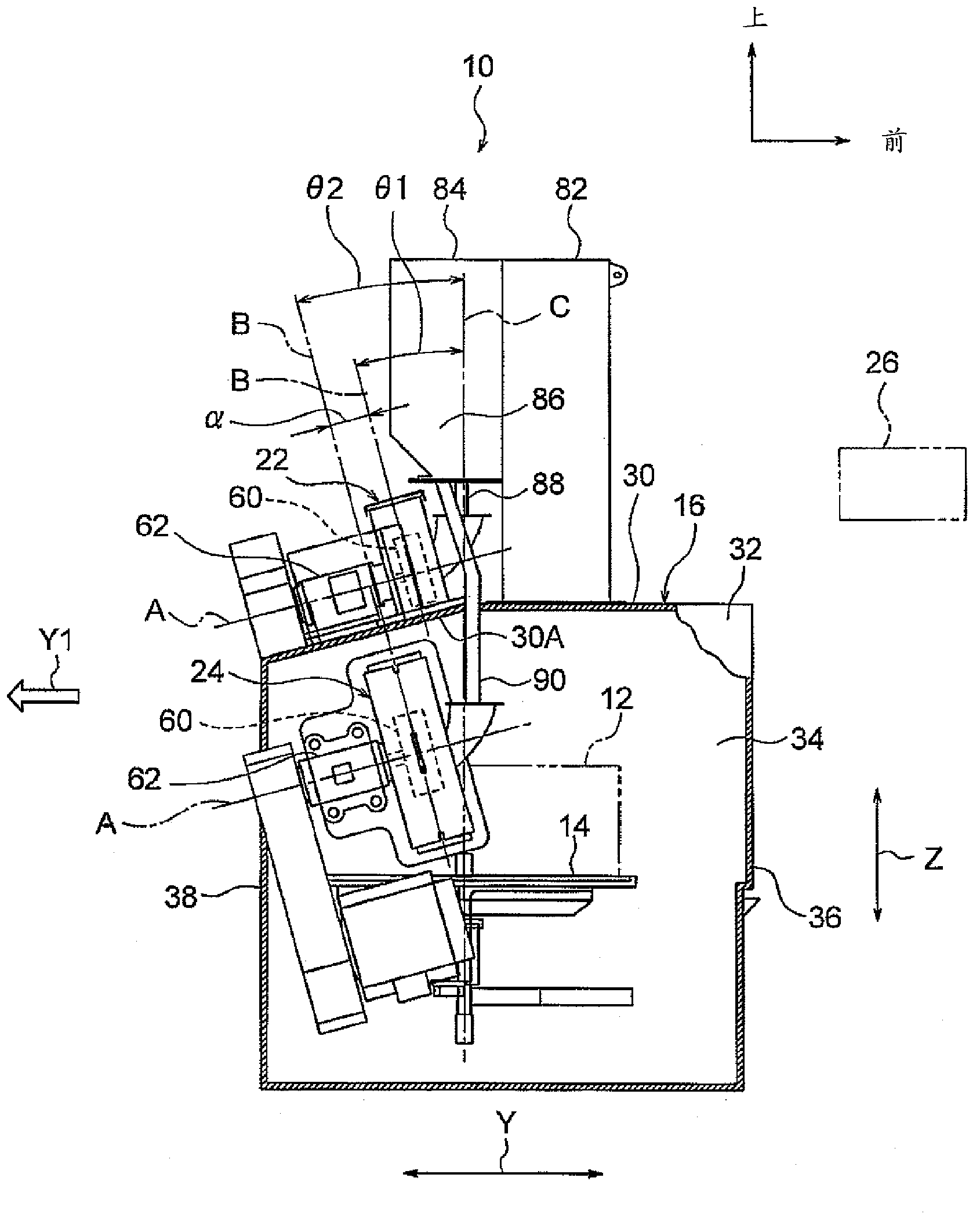

[0027] First, a first embodiment of the present invention will be described.

[0028] In addition, the arrow front, upper side, and left shown in each figure represent the front side, upper side, and left side of the shot processing apparatus 10 demonstrated below.

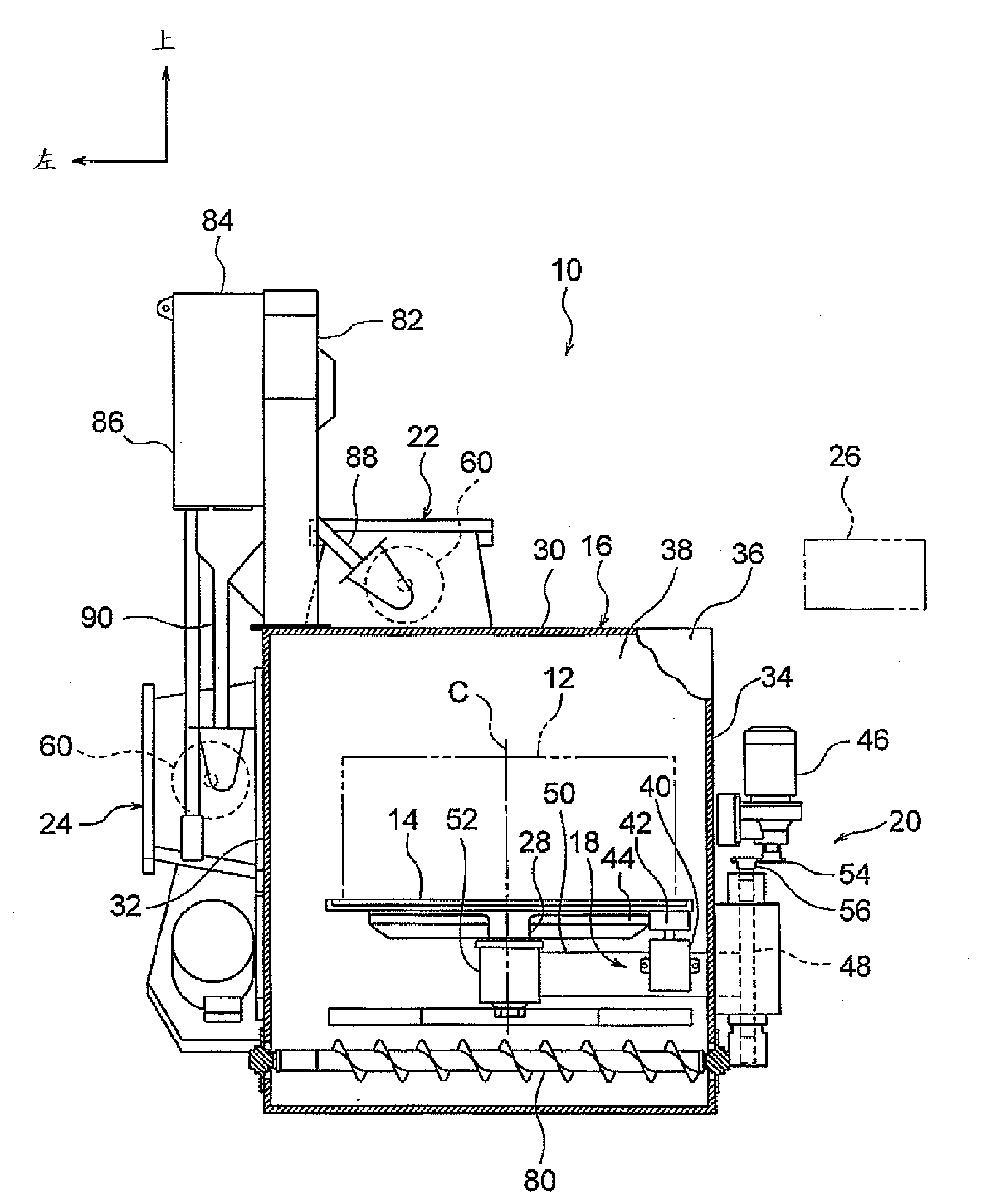

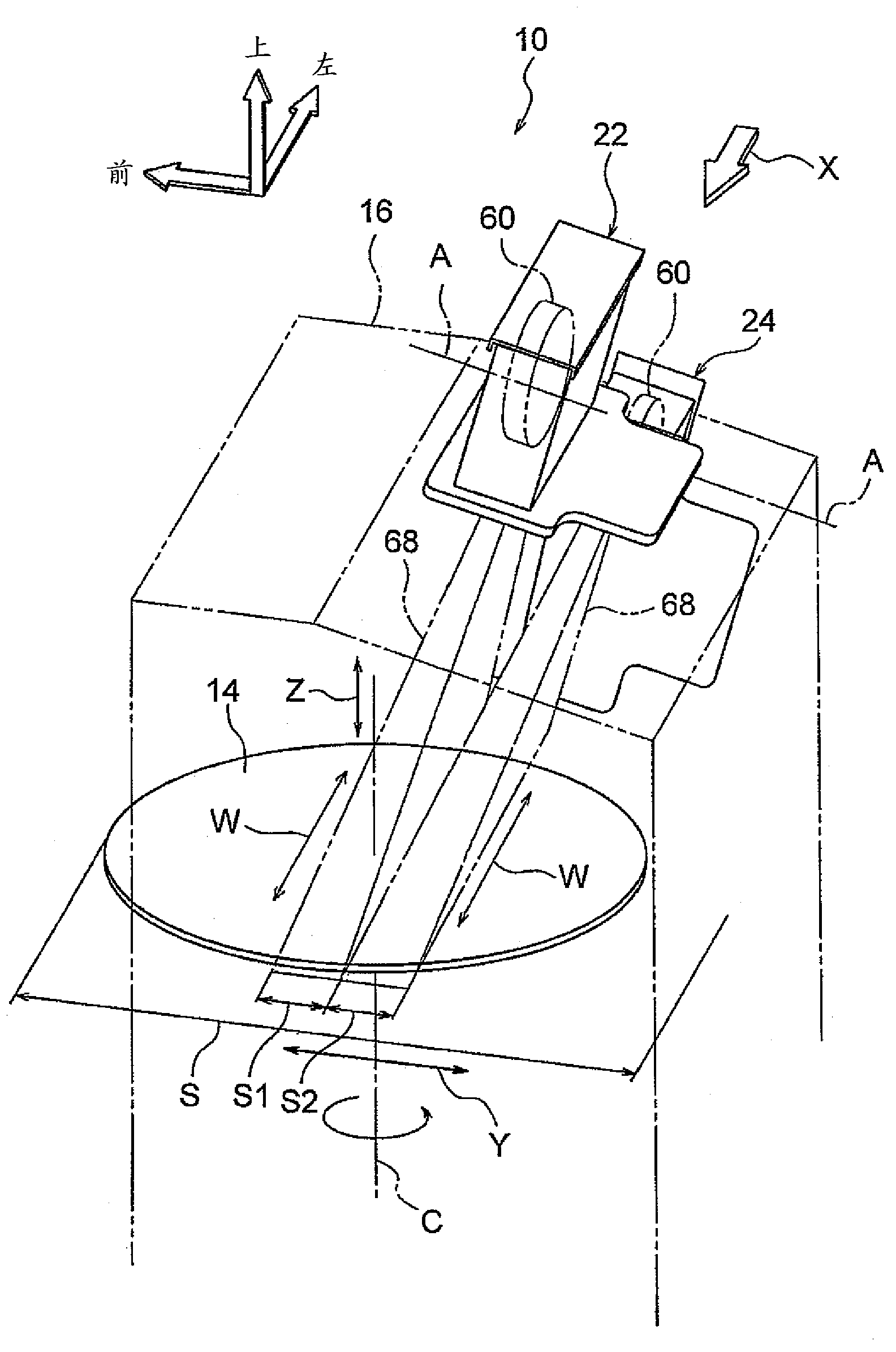

[0029] Such as figure 1 As shown, the shot peening apparatus 10 according to the first embodiment of the present invention is, for example, a shot peening apparatus used to remove scale attached to a metal workpiece 12, and the shot peening apparatus 10 includes a holding tool 14, The shot blasting chamber 16, the rotation drive part 18, the slide drive part 20, a pair of centrifugal projection machines 22 and 24, and the control part 26.

[0030] The holding tool 14 is formed in a disk shape and is arranged horizontally. A shaft portion 28 extending downward along the height direction of the shot blasting apparatus 10 is formed at a central portion on the back side of the holder 14 . Furthermore, the shaft par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com