Punching die of vacuum booster upper push rod assembly

A technology of vacuum booster and push rod, which is applied in the direction of piercing tools, manufacturing tools, and pushing equipment, etc., which can solve the troublesome problems of waste disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

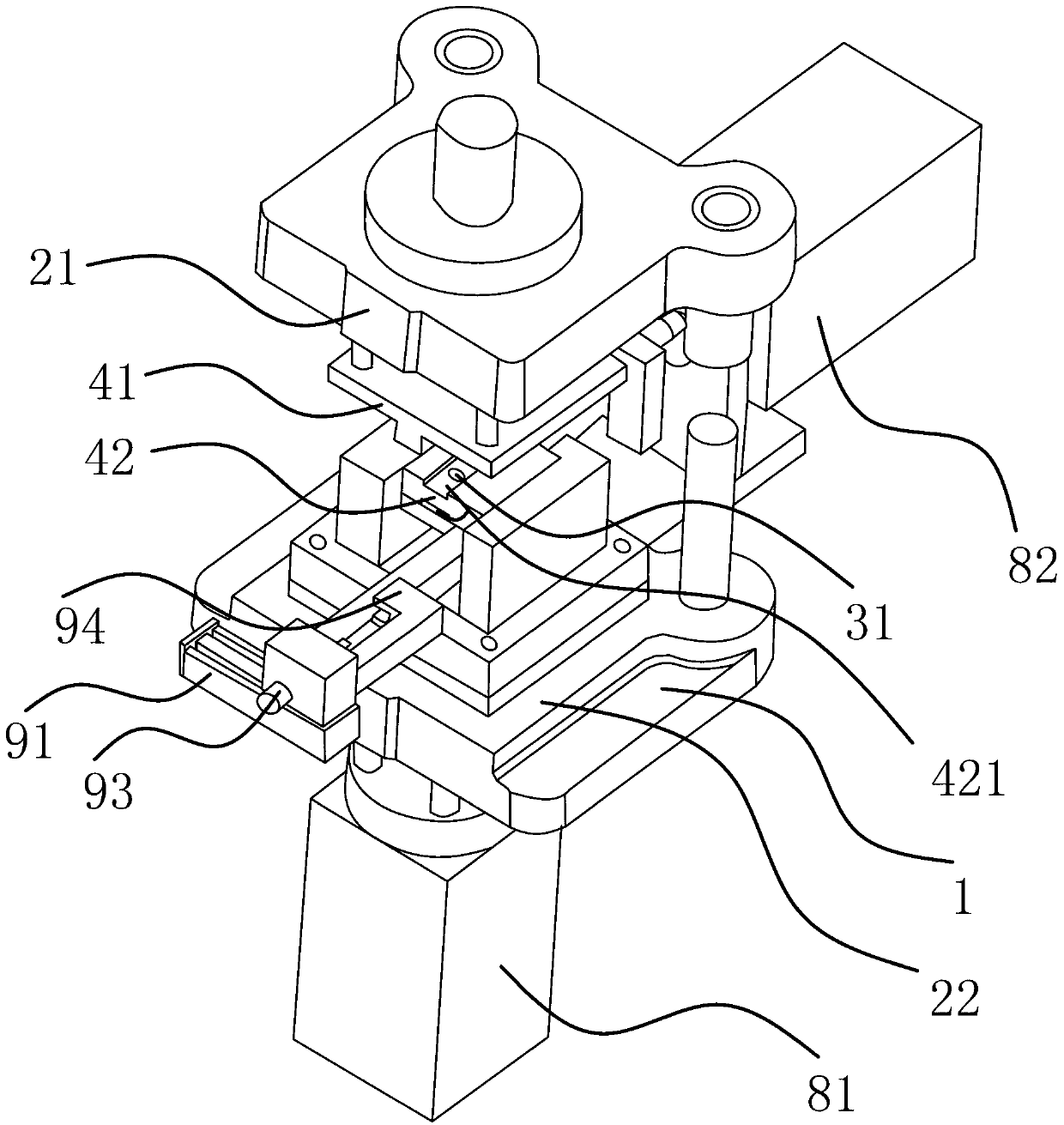

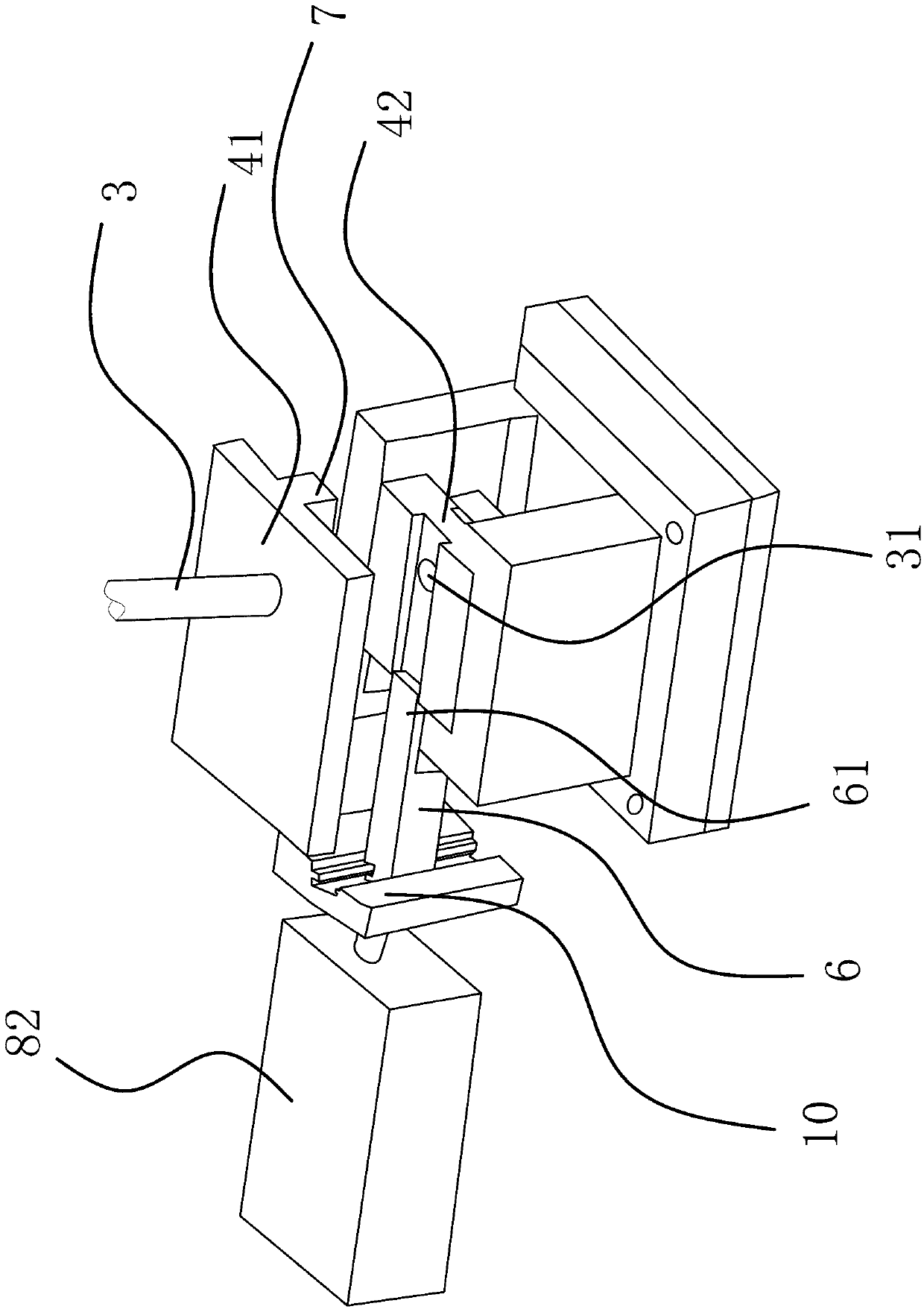

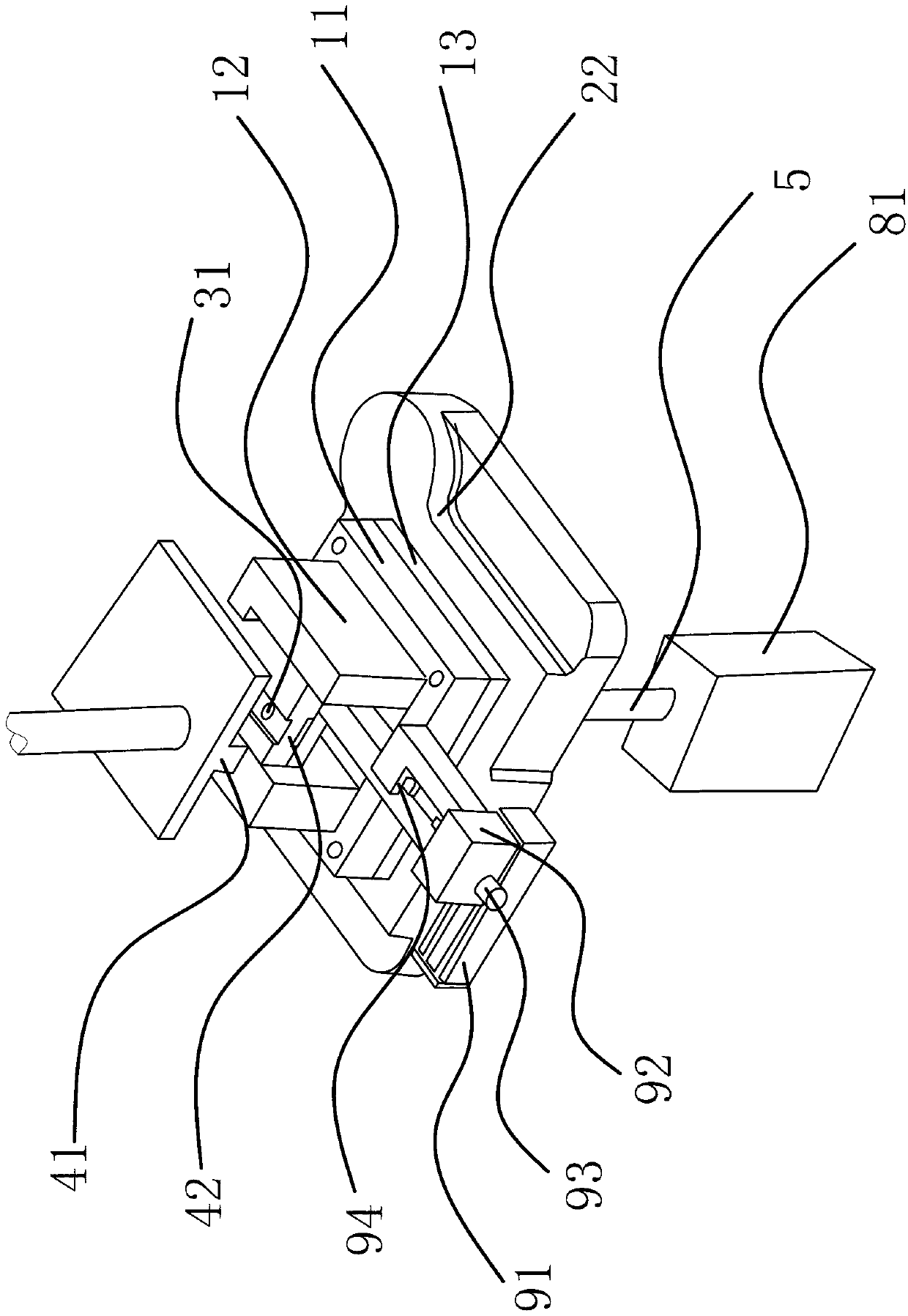

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, this punching die comprises frame 1, upper mold base 21, punch 3, and horizontally arranged punch 41 and die 42, and the upper surface and lower surface of die 42 are respectively provided with a connected bar-shaped groove 421, the punch 3 is arranged on the upper die base 21 in the vertical direction and is facing the bar-shaped groove 421, and the punch 41 and the die 42 are provided with the punch 3 directly below and allow The through hole 31 that the punch 3 passes through, the lower end of the frame 1 is provided with a waste push rod 5 that pushes away the waste generated by the workpiece from the die 42 after the punching is completed, and the rear end of the frame 1 is provided with a The workpiece can be pushed away from the ejector push rod 6 of the die 42, and the punch 41 is provided with an alignment plate 7, which can lean against the bar-shaped groove 421 on the upper surface of the die ...

Embodiment 2

[0030] Such as figure 2 and Figure 6 As shown, the content of this embodiment is roughly the same as that of Embodiment 1, except that the ejector structure includes a support arm 2 95 fixed on the frame 1 and a slider 2 96 that can slide back and forth on the support arm 2 95 The slider 2 96 is located directly in front of the bar-shaped groove 421, and the slider 2 96 is provided with a notch 97 that can be sleeved on one end of the workpiece to hold the workpiece up. The end of the connecting rod 14 of the workpiece is against the In the notch 97, slide block 2 96 and support arm 2 95 belong to a tight fit, and slide block 2 96 will not loosen after adjusting the position with the strip groove 421. Pushing slide block 2 96 back and forth makes the workpiece The two connecting arms 15 abut against the strip-shaped groove 421 .

[0031] The working principle of this punching die is: the workpiece mentioned in this manual refers to the upper push rod assembly of the vacuum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap