A method for rolling checkered plates from thin slabs

A technology of thin slabs and checkered plates, which is applied in metal rolling, workpiece heating devices, workpiece cooling devices, etc., can solve the problems of high inventory pressure, long time in the furnace, low profit, etc., to reduce temperature drop and increase added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

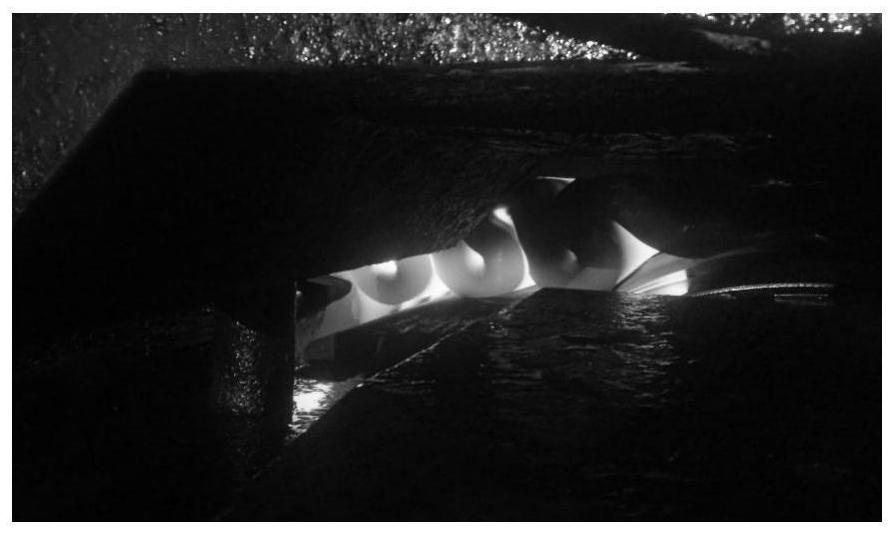

Image

Examples

Embodiment

[0035] 1. Heating continuous casting slab:

[0036] ESP thin slab thickness 90mm.

[0037] Formulate reasonable furnace control parameters and furnace time, specifically to reduce the furnace temperature of the heating furnace and reduce the time of thin slabs in the furnace.

[0038] The heating parameters (furnace temperature) are: preheating 700-800°C, one plus 850-950°C, two-plus 1140-1180°C, soaking 1170-1200°C. During steel loading, control is carried out according to the minimum value of the above-mentioned heating parameters. 15 minutes before tapping the steel, two additions are added, the temperature is soaked at 20-30°C, and the descaling temperature after the furnace is controlled at 1100-1130°C.

[0039] After the ESP thin slab walks to the door of the tapping furnace, it is tapped immediately, and the furnace time is controlled at 130±10min. Thin slabs run at the fastest pace in the furnace, implementing a low-temperature and fast-out plan.

[0040] Result: if...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com