5005 aluminum alloy for high compressive strength handle and preparation method thereof

A compressive strength, aluminum alloy technology, applied in the field of 5005 aluminum alloy for high compressive strength handles and its preparation, can solve the problems of handle bending deformation, poor compressive strength, easy to clip to the refrigerator handle, etc., to achieve compressive strength Improve, save cost, save material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

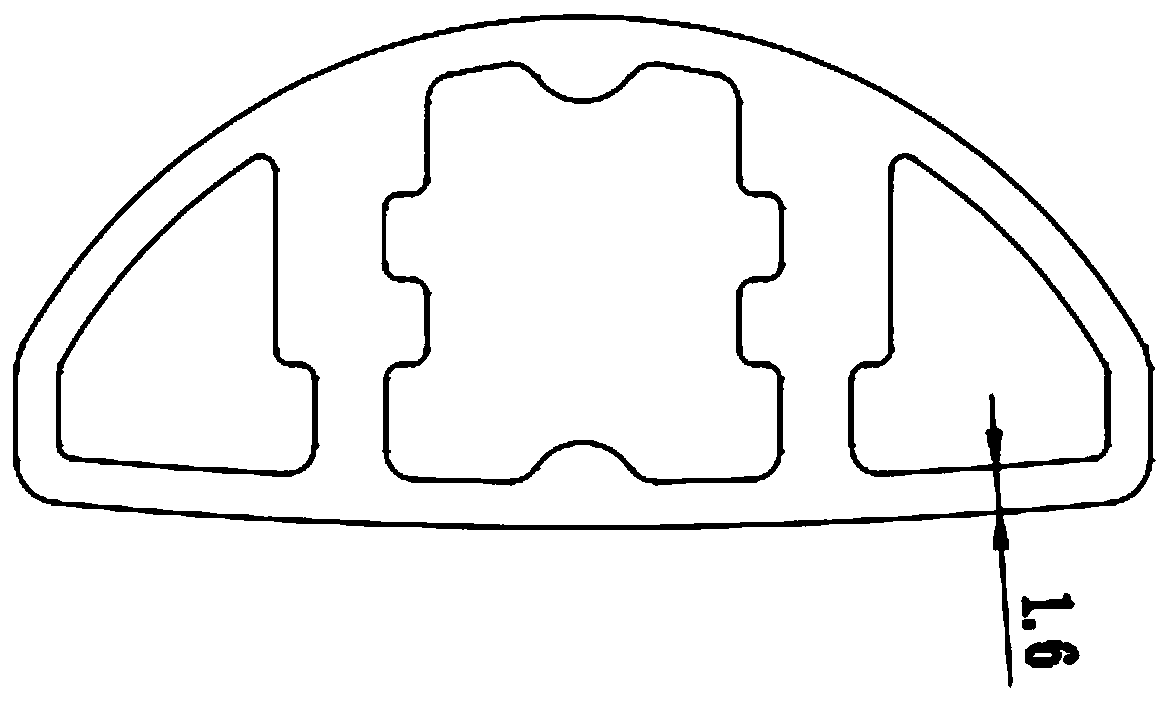

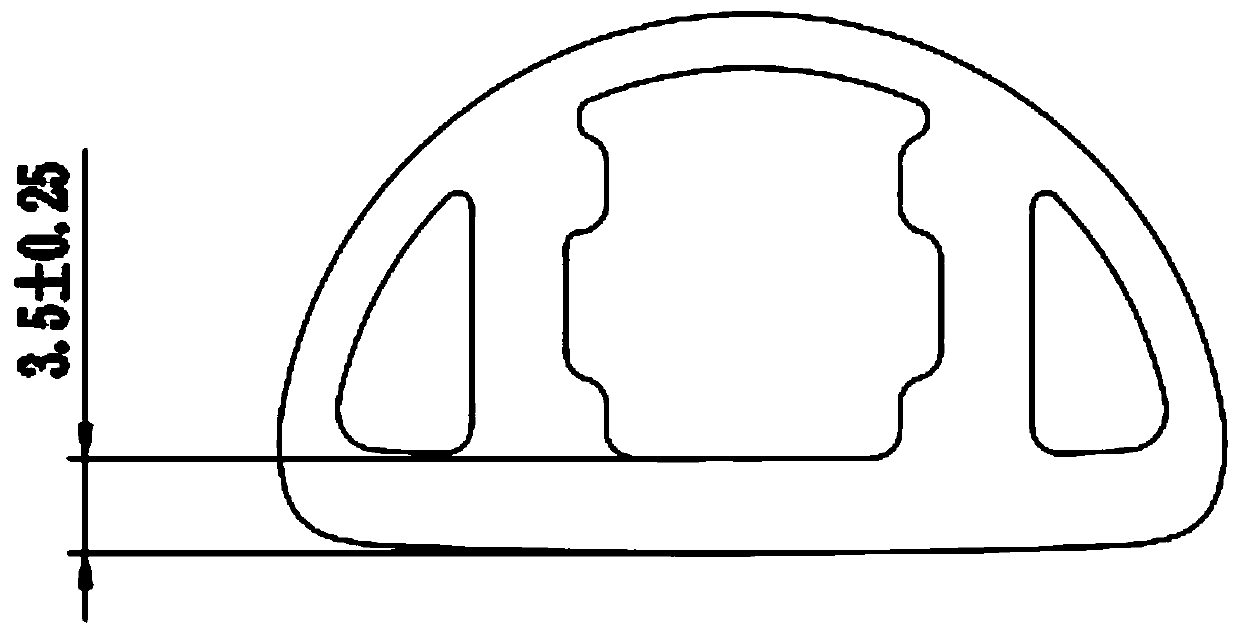

Image

Examples

Embodiment 1

[0026] Percentage by weight: Mg: 1.1%, Si: 0.17%, Fe: 0.01%, Cr: 0.01%, Mn≤0.02%, Zn≤0.03%, Cu≤0.02%, individual content of other impurity elements≤0.02%, others The total content of impurity elements is less than or equal to 0.15%, and the balance is Al. The ingredients are prepared and prepared according to the following steps:

[0027] (1) Smelting: put aluminum ingots with a purity of 99.75% or more into the melting furnace, and add magnesium ingots and aluminum-silicon intermediate alloys in proportion. Send it into the melting furnace and move slowly in the melting furnace until the magnesium ingot is completely melted. The furnace charge is heated and melted in the melting furnace and stirred for 20-30 minutes. After sampling and analysis of components, it is transferred to the holding furnace. The melting temperature is 700-750 ° C. Melting time is 7-8 hours;

[0028] (2) Refining: Refining the molten aluminum in the holding furnace, inserting the blowing head of the ...

Embodiment 2

[0034]Percentage by weight: Mg: 1.2%, Si: 0.20%, Fe: 0.02%, Cr: 0.01-0.03%, Mn≤0.02%, Zn≤0.03%, Cu≤0.02%, other impurity elements single content≤0.02% , the total content of other impurity elements ≤ 0.15%, the balance is Al, carry out batching, and prepare according to the following steps:

[0035] (1) Smelting: put aluminum ingots with a purity of 99.75% or more into the melting furnace, and add magnesium ingots and aluminum-silicon intermediate alloys in proportion. Send it into the melting furnace and move slowly in the melting furnace until the magnesium ingot is completely melted. The furnace charge is heated and melted in the melting furnace and stirred for 20-30 minutes. After sampling and analysis of components, it is transferred to the holding furnace. The melting temperature is 700-750 ° C. Melting time is 7-8 hours;

[0036] (2) Refining: Refining the molten aluminum in the holding furnace, inserting the blowing head of the rotary blowing and degassing device into...

Embodiment 3

[0042] Percentage by weight: Mg: 1.25%, Si: 0.22%, Fe: 0.03%, Cr: 0.01-0.03%, Mn≤0.02%, Zn≤0.03%, Cu≤0.02%, other impurity elements single content≤0.02% , the total content of other impurity elements ≤ 0.15%, the balance is Al, carry out batching, and prepare according to the following steps:

[0043] (1) Smelting: put aluminum ingots with a purity of 99.75% or more into the melting furnace, and add magnesium ingots and aluminum-silicon intermediate alloys in proportion. Send it into the melting furnace and move slowly in the melting furnace until the magnesium ingot is completely melted. The furnace charge is heated and melted in the melting furnace and stirred for 20-30 minutes. After sampling and analysis of components, it is transferred to the holding furnace. The melting temperature is 700-750 ° C. Melting time is 7-8 hours;

[0044] (2) Refining: Refining the molten aluminum in the holding furnace, inserting the blowing head of the rotary blowing and degassing device in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com