Mounting structure for anti-side-rolling torsion bar base of railway vehicle

A technology of anti-rolling torsion bar and installation structure, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, which can solve problems such as poor stress conditions, and achieve convenient and quick installation, simple structure, and guaranteed strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

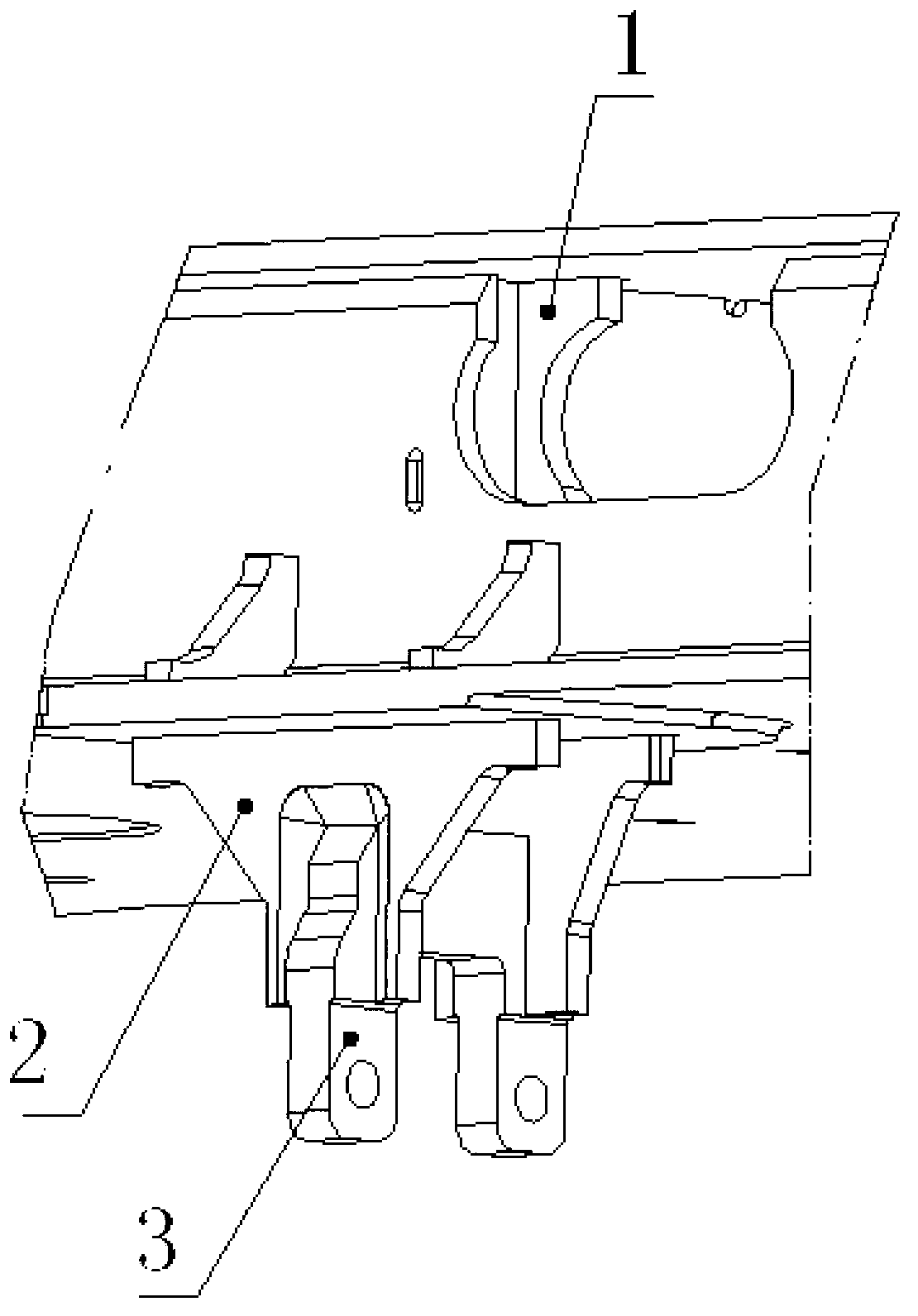

[0015] The rail vehicle anti-roll torsion bar installation seat installation structure of this embodiment includes a first web 1 with slots, a second web 2 and an anti-roll torsion bar installation block 3 .

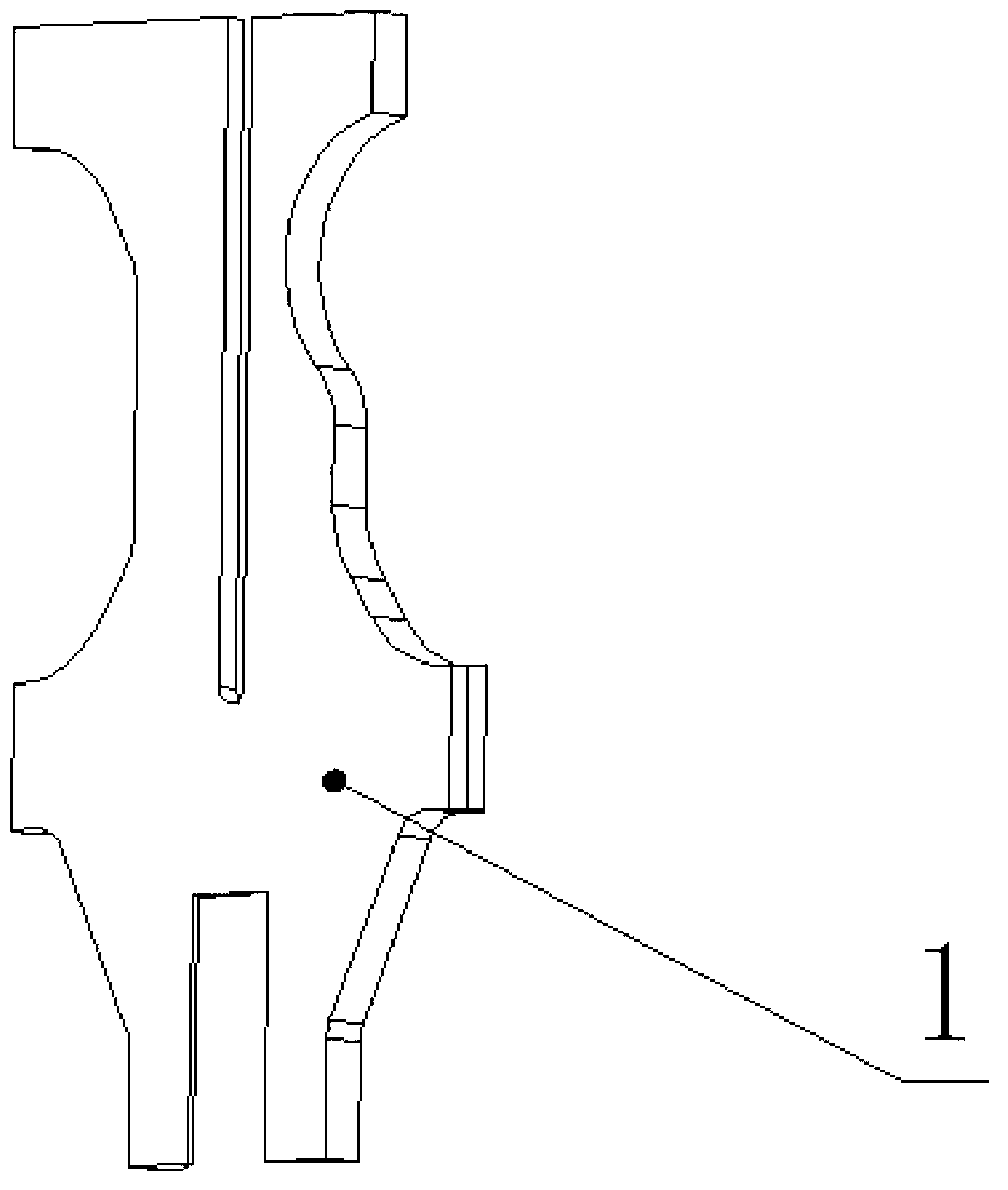

[0016] Such as figure 2 As shown, the upper part of the first web 1 is provided with an upward-opening slot for inserting the inner partition of the corbel, and the bottom of the first web 1 is provided with a downward-opening groove. When in use, the first web 1 is plugged into the inner partition of the corbel and welded with the inner partition, and its top is welded on the upper cover of the corbel; slots are made on the lower cover of the corbel, and the first The web 1 passes through the groove on the lower cover of the corbel, and the middle part of the first web 1 is welded on the lower cover of the corbel.

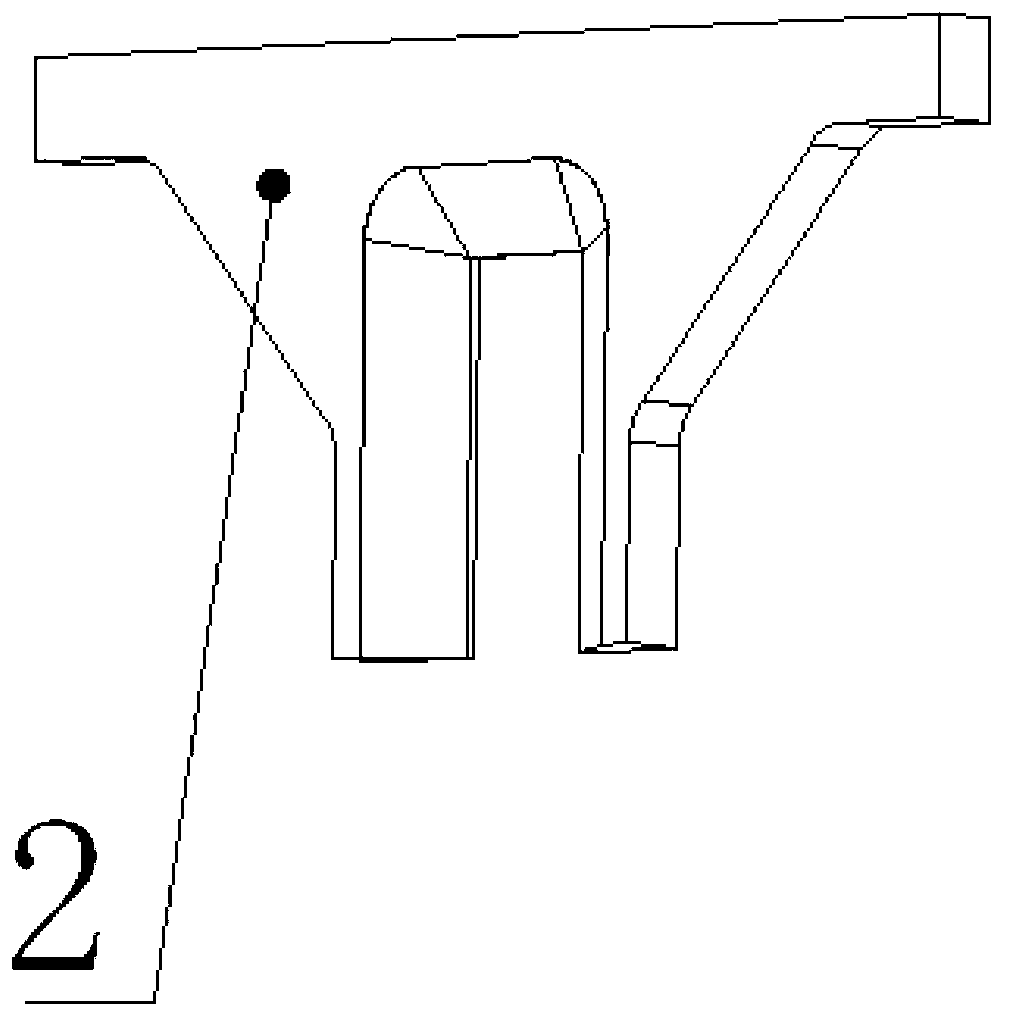

[0017] Such as image 3 As shown, the bottom of the second web 2 has a groove opening downward. When in use, the top of the second web 2 is directly ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com