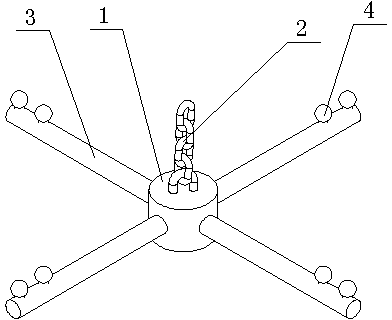

Lifting tool for forklift

A technology of spreaders and forklifts, applied in the direction of lifting devices, etc., can solve problems such as low work efficiency and waste of human resources, and achieve the effects of reducing labor intensity, saving labor costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

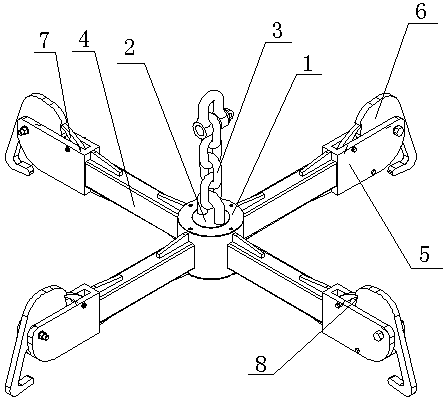

[0016] See figure 2 , a kind of spreader for forklift, comprises ring-shaped center frame 1, the central axis 2 that is arranged on the inner ring of center frame 1, the chain 3 that is arranged on the top of center axis 2 and is evenly distributed on the outside of center frame 1 along the circumference of center frame 1 Four hangers 4 on the wall, the outer end of each hanger 4 is all provided with U-shaped clamping plate 5, and U-shaped clamping plate 5 is provided with the hook 6 that is rotatably connected with U-shaped clamping plate 5, and U-shaped clamping plate 5 A ratchet 7 which is rotatably connected to the U-shaped clamping plate 5 is provided on the inside of the hook 6 in the plate 5 , and the inner end of the hook 6 is provided with a limiting groove 8 for engaging with the outer end of the ratchet 7 .

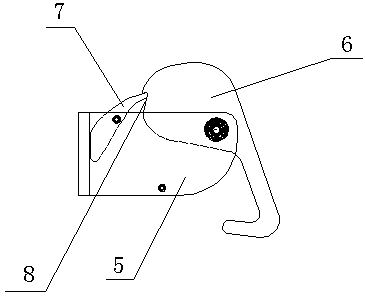

[0017] See image 3 , before lifting the goods, the hook 6 and the pawl 7 are set at the initial position for positioning, that is, the outer end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com