Hot-pressing resistance measuring machine for battery cells

A battery cell and resistance technology, applied in the direction of measuring resistance/reactance/impedance, measuring devices, measuring electrical variables, etc., can solve problems such as differences in resistance readings, heavy labor, inconsistent methods, etc., to achieve stable resistance readings and easy operation The effect of less movement and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

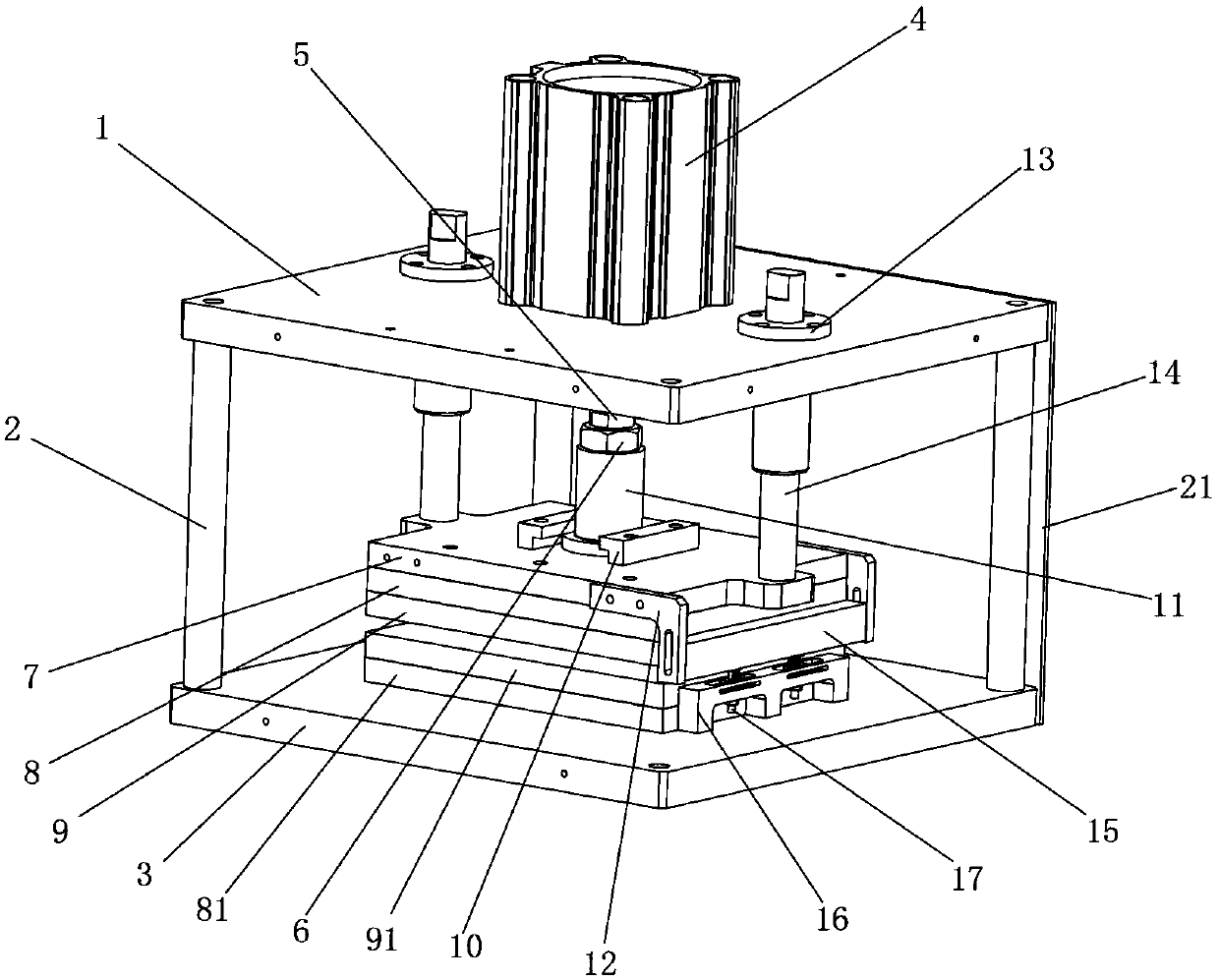

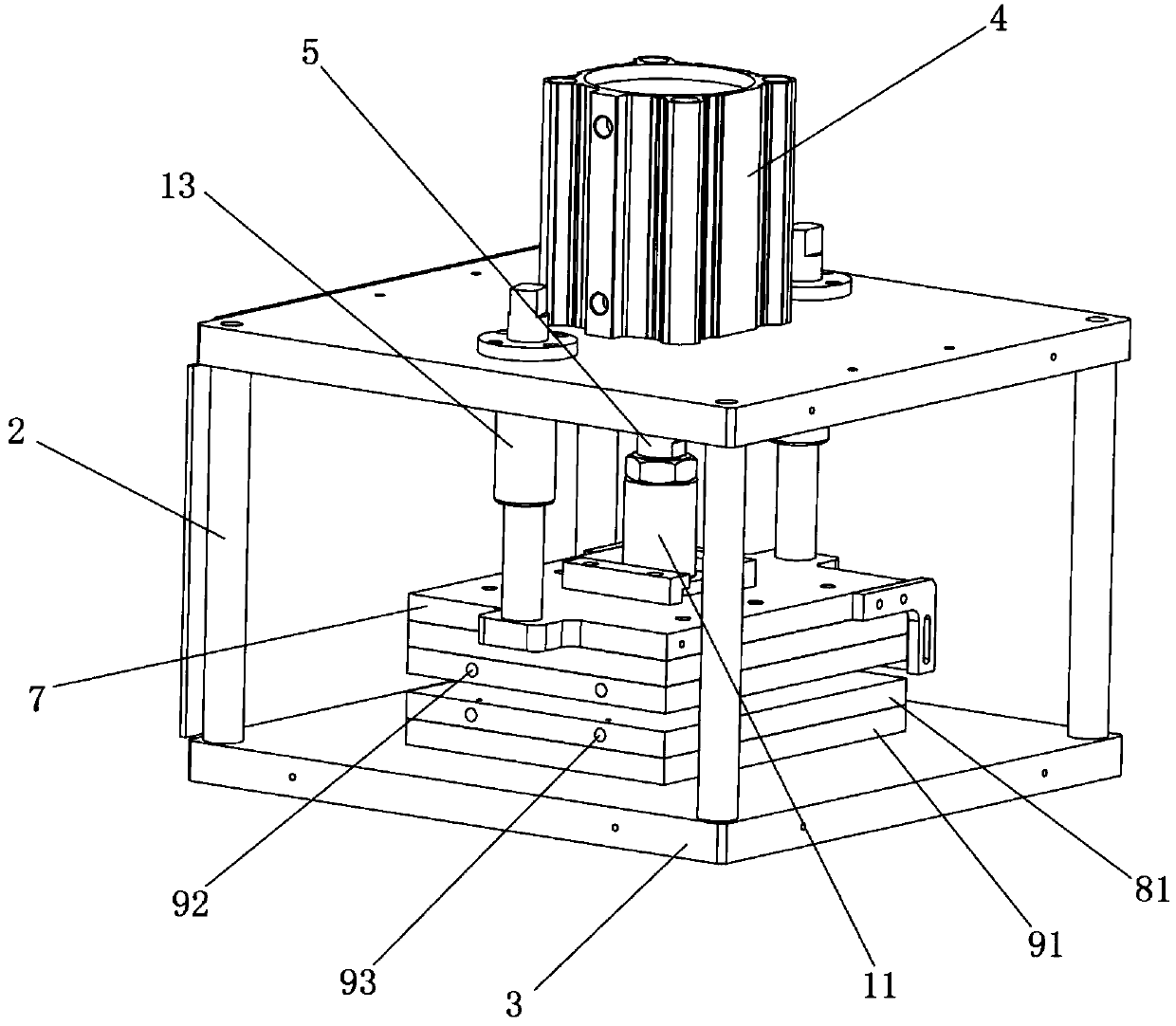

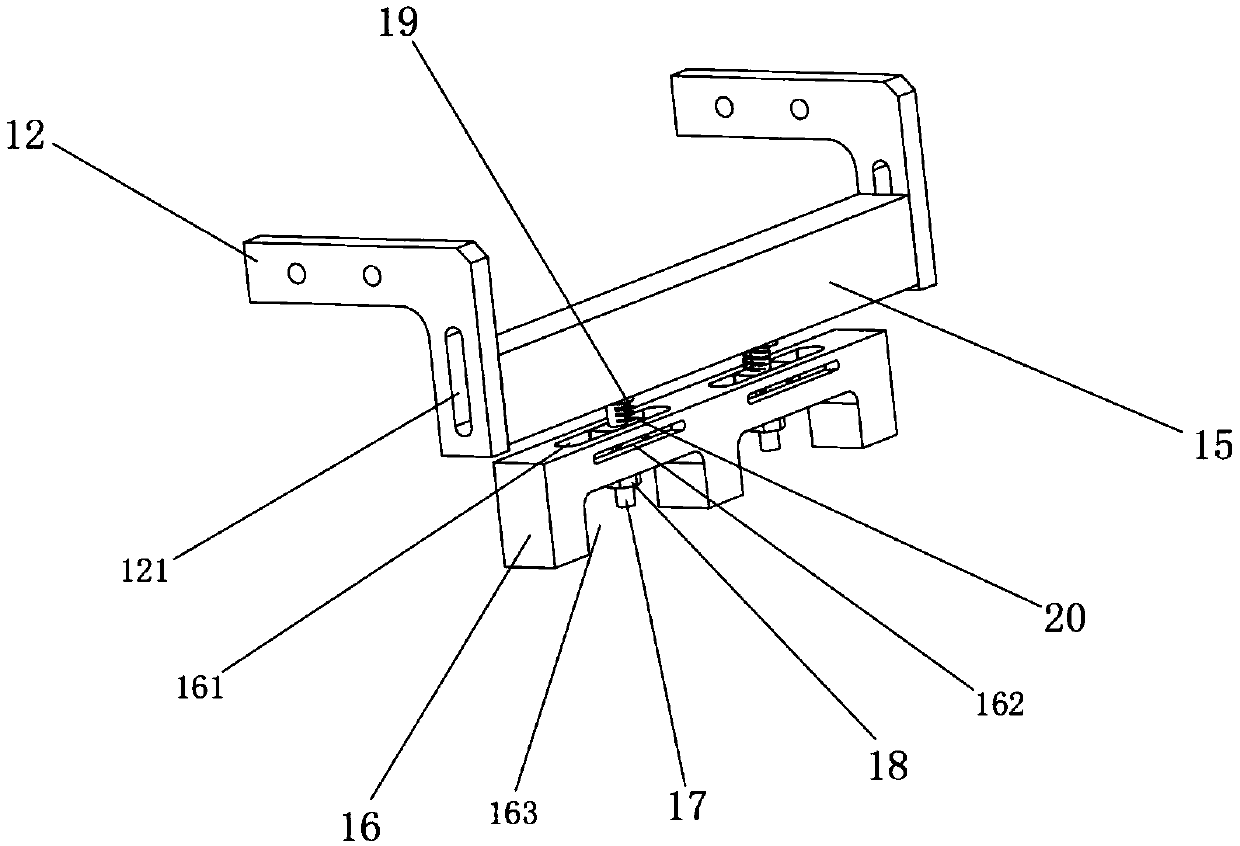

[0060] A thermal piezo resistance measuring machine for battery cells, such as figure 1 , figure 2 , image 3As shown, it includes a cylinder plate 1 and a base plate 3, a column 2 is connected between the cylinder plate 1 and the base plate 3; a pressurized cylinder 4 is connected to the cylinder plate 1; the cylinder movable rod 5 of the pressurized cylinder 4 Through the cylinder plate 1, and the cylinder movable rod 5 is vertically downward; the cylinder movable rod 5 is connected with the cylinder joint 11 through the movable rod nut 6, and the cylinder joint 11 and the cylinder movable rod 5 can be adjusted by the movable rod nut 6 The cylinder joint 11 is connected with a pressure plate 7; the pressure plate 7 is provided with two pressure plate joints 10 at intervals, and a connection that matches the flange on the cylinder joint 11 is formed between the two pressure plate joints 10 Groove, the upper flange of the cylinder joint 11 is connected with the connection g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com