Turning butt-jointing machine for electrolytic manganese negative plate

A technology that turns to docking machine and cathode plate, and is applied in the direction of electrolysis process, electrolysis components, photography process, etc., to achieve the effect of improving the peeling effect and realizing the automatic production of the assembly line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

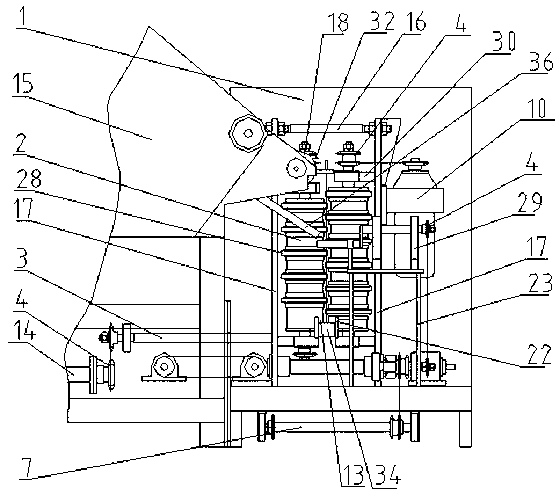

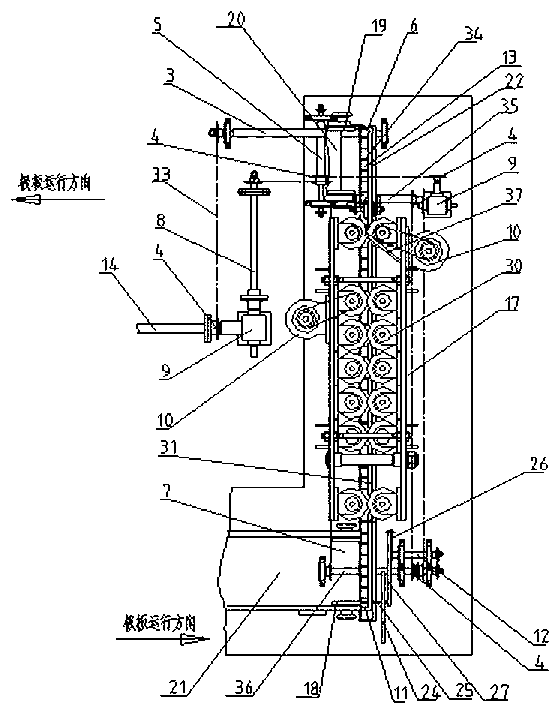

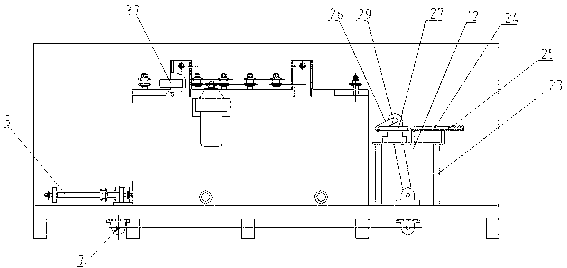

[0019] Such as figure 1 , figure 2 and image 3 As shown, the frame 1 is set between the plate channel 21 of the stripper and the plate channel 20 of the plate washer, and the plate transition guide wheels 18 are symmetrically installed on both ends of the plate channel 21 of the stripper. The pole plate anti-swing spring guide bar 36 is installed on the end outer side plate of the stripping machine pole plate output channel 21 to prevent the pole plate from swinging back and forth when it is put down from the stripping machine and enters into the docking machine. Two vertical boards 17 are installed on the frame 1, and are connected by adjusting screw rod 16 between the two vertical boards 17, and the distance between the two vertical boards 17 can be adjusted by adjusting screw rod 16. The upper and lower ends of each vertical plate 17 inboards are provided with a plurality of bearing blocks 30, and the conveying roller 2 is installed between the upper and lower bearing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com