Film stripping liquid for polyimide adhesive film and preparation method of film stripping liquid

A technology for polyimide adhesive film and film stripping, which is applied in the field of stripping liquid for polyimide adhesive film and its preparation, can solve the problems of lack of glue, corroded substrate, polluted thickness, etc., so as to improve the film stripping efficiency. effect, speeding up the peeling speed, and the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

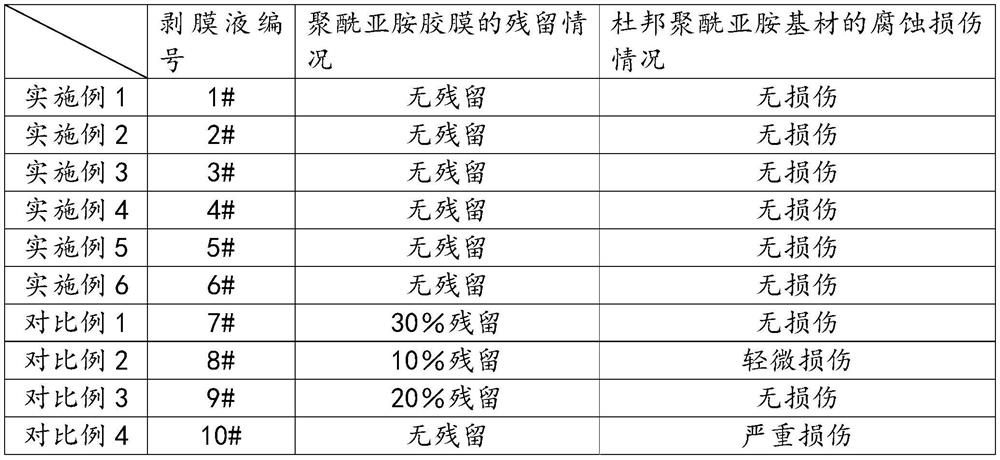

Examples

preparation example Construction

[0030] A preparation method of a stripping liquid for a polyimide adhesive film of the present invention comprises the following steps:

[0031] First, 60 parts by weight of one or more of the above-mentioned ether organic solvents, 20 parts by weight of one or more of the above-mentioned aliphatic amines, 1.5 parts by weight of one or more of the above-mentioned anionic surfactants, 15 parts by weight of the above-mentioned One or more of alcoholic solvents and 1.5 parts by weight of one or more of above-mentioned inorganic bases are successively added in the container and mixed;

[0032] Then, under normal temperature conditions, the material in the above-mentioned container is stirred, the rotational speed of the stirrer is adjusted to be 400 rpm to 600 rpm, preferably 500 rpm, and the stirring time is 8 to 12 minutes, preferably 10 minutes. , and after the stirring is completed, the stripping solution for a polyimide adhesive film of the present invention can be obtained. ...

Embodiment 1

[0034] Add 50g tripropylene glycol methyl ether, 13g 1,4-butanediamine, 14g hexanediamine, 1g sodium lauryl sulfate, 1g sodium hexadecyl sulfate, 10g isopropanol, 10g n-propanol and 1g sodium hydroxide Mix in a container, and then stir for 10 minutes at room temperature with a stirring speed of 500 rpm to obtain film stripping solution 1#.

Embodiment 2

[0036] 30g tripropylene glycol methyl ether, 40g ethylene glycol tert-butyl ether, 10g 1,2-dimethylpropylamine, 8g 1,2-propanediamine, 1g sodium dodecylbenzenesulfonate, 5g isopropanol, 5g Methanol and 1 g of potassium hydroxide were added to the container and mixed, and then stirred at a stirring speed of 500 rpm at room temperature for 10 minutes to obtain film stripping solution 2#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com