A kind of degumming liquid and its preparation method and application

A technology of degumming solution and inorganic base, which is applied in the direction of chemical instruments and methods, detergent compositions, surface active detergent compositions, etc., can solve the problems of organic solvent volatilization by heat, unfavorable health of staff, and pollution of working environment, etc. Achieve the effects of reasonable formula, extended shelf life, stable and safe ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

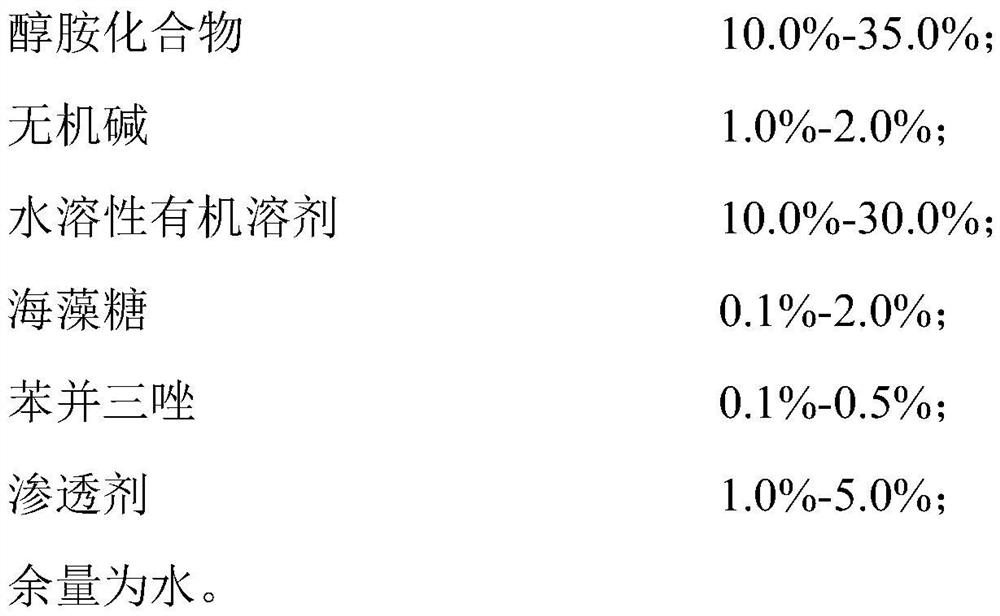

Method used

Image

Examples

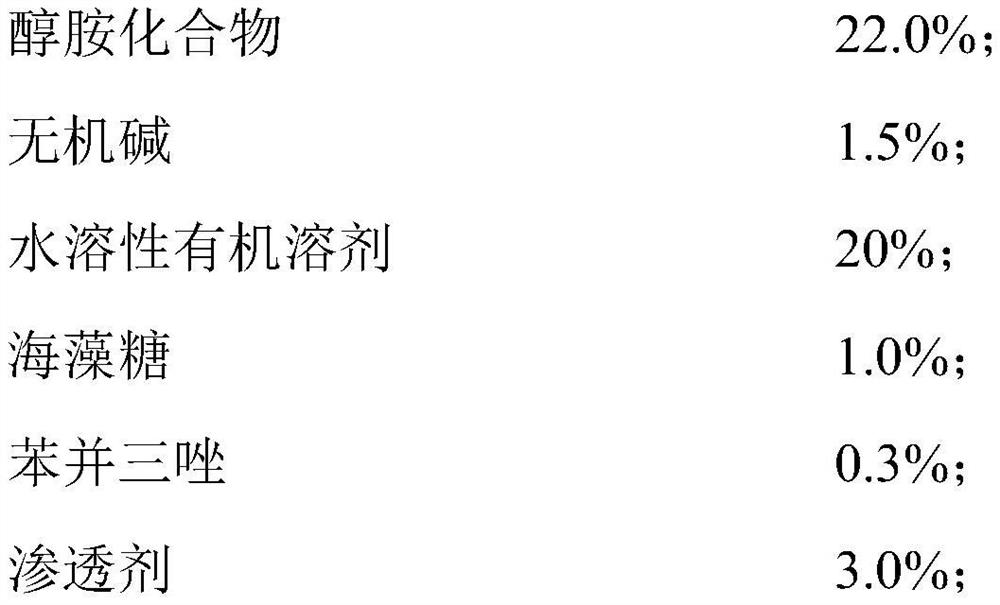

Embodiment 1

[0030] The degumming solution provided in this example has the following formula: 47.7kg of water, 20kg of sulfolane, 22kg of diethanolamine, 1.5kg of sodium hydroxide, 1kg of trehalose, 0.3kg of benzotriazole and 3kg of dioctyl sodium sulfosuccinate .

[0031] The preparation method of the degumming solution provided in this example includes the following steps: sequentially weigh each raw material component of the above formula, transfer it to the reaction kettle by a pneumatic diaphragm pump, and stir for 300s in a regular cycle to allow the various raw materials to mix and react evenly , It is obtained after filtering with a precision filter, and is filled with a precision automatic filling machine after passing the inspection.

Embodiment 2

[0033] The present embodiment provides glue removing solution, its formula is as follows: water 55.3kg, sulfolane 25kg, diethanolamine 15kg, potassium hydroxide 1.8kg, trehalose 0.5kg, benzotriazole 0.4kg and fatty alcohol polyoxyethylene ether 2kg, prepare Method is with embodiment 1.

Embodiment 3

[0035] The degumming solution provided in this embodiment has the following formula: 48.1kg of water, 15kg of N-methylpyrrolidone, 30kg of monoethanolamine, 1.2kg of sodium hydroxide, 1.5kg of trehalose, 0.2kg of benzotriazole and fatty alcohol polyoxygen Vinyl ether 4kg, preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com