Circuit board and solder structure

A welding structure and circuit board technology, which is applied in the direction of circuit board tool positioning, printed circuit, printed circuit manufacturing, etc., can solve the problems that the antenna shrapnel can not be welded in the correct direction and position, the cost and time, and error-prone, etc., to achieve Avoid pasting mistakes, reduce the error rate, avoid the effects of reverse pasting or misplacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the circuit board design for preventing the 180-degree reverse attachment of the antenna shrapnel provided by the present invention will be described in detail below with reference to the accompanying drawings.

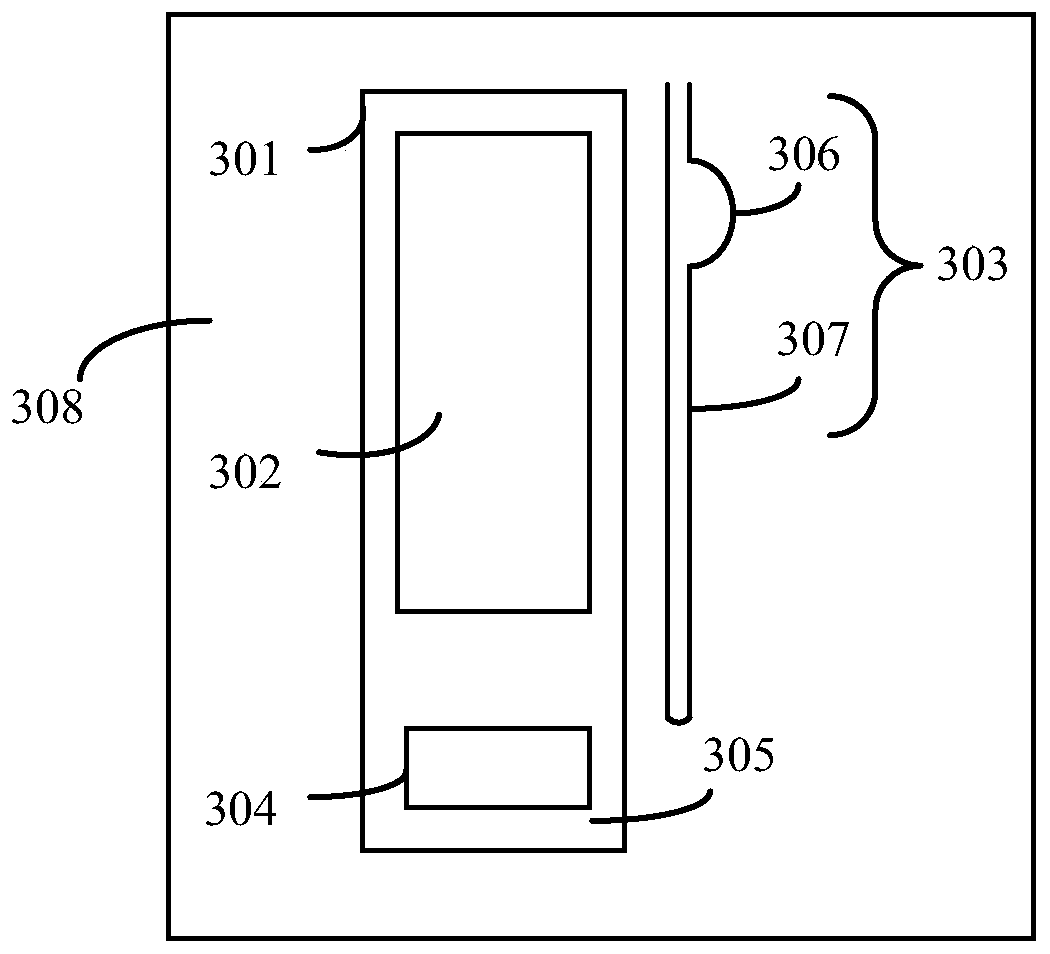

[0025] Please refer to image 3 , is a schematic diagram of a circuit board according to a specific embodiment of the present invention.

[0026] The circuit board includes: a base plate 308; an outer frame line 301 located on the surface of the base plate 308; a pad 302 located on the surface of the base plate 308 within the outer frame line 301; a surface of the base plate 308 located on at least one side of the outer frame line 301 The identification pattern 303 is used to identify the welding position between the pad 302 and the object to be welded.

[0027] The area inside the outer frame line 301 is the area where the solder is located after being soldered to the circuit board. The object to be soldered includes a solderin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com