A kind of ultra-thin wafer with reverse mesa composite structure and its preparation method

A composite structure and wafer technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as surface finish decline, poor mechanical properties, rough surface structure, etc. Good use stability, not easy to be broken by force, and high surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

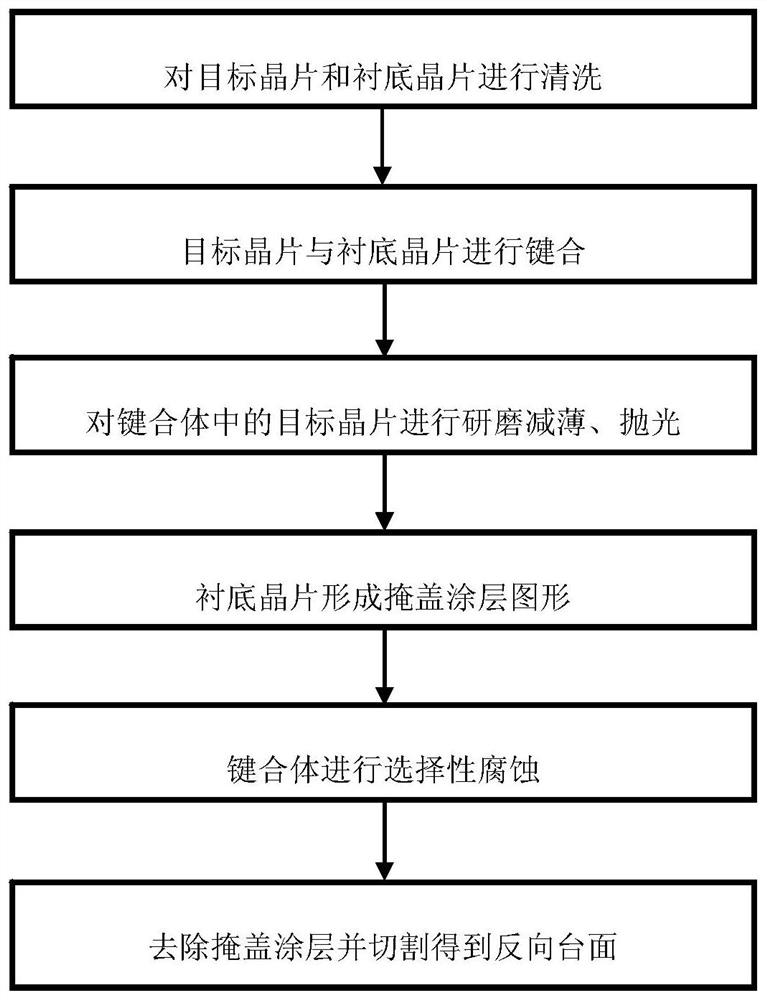

[0036] The present invention also includes a method for preparing an ultra-thin wafer with a reverse mesa composite structure, comprising the following steps:

[0037] ① Prepare the target wafer and the substrate wafer, clean and bond them respectively to obtain a bonded body; the target wafer is quartz, single crystal lithium tantalate, single crystal lithium niobate, silicon carbide or gallium arsenide; the substrate wafer is a silicon wafer, quartz wafer or glass wafer;

[0038] The prepared target wafer can be non-polished or a large-sized wafer (such as 3~6 inches) with single-sided and double-sided mirror polishing. The surface of the target wafer can be polished by chemical mechanical polishing. The surface roughness of the target wafer It is less than 1nm to meet the requirements of direct bonding; the target wafer can also be ground and thinned before polishing, and the TTV of the target wafer can be adjusted (thickness variation is less than 1 μm) to meet the thickne...

Embodiment 1

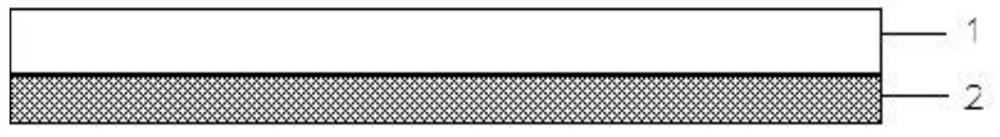

[0055] An ultra-thin wafer with a reverse mesa composite structure, including a target wafer and a substrate wafer positioned at the bottom of the target wafer with a supporting function, wherein the thickness of the target wafer is 2 μm, and a flat sheet with an overall thickness deviation of 0.005 to 1 μm, and the substrate wafer is frame structure; the target wafer is quartz; the substrate wafer is a silicon wafer.

Embodiment 2

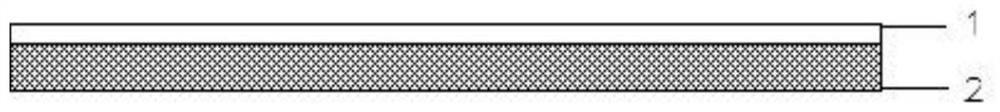

[0057] An ultra-thin wafer with a reverse mesa compound structure, including a target wafer and a substrate wafer at the bottom of the target wafer with a supporting function, wherein the target wafer is a flat sheet with a thickness of 80 μm and an overall thickness deviation of 0.005 to 1 μm, and the substrate wafer is frame structure; the target wafer is single crystal lithium tantalate; the substrate wafer is a quartz wafer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com