Fully-automated ramie decorticator

A hemp stripping machine, fully automatic technology, applied in mechanical processing, fiber mechanical separation, textiles and paper making, etc., can solve the problems of poor stripping effect, achieve good stripping effect, improve stripping effect, and closely cooperate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

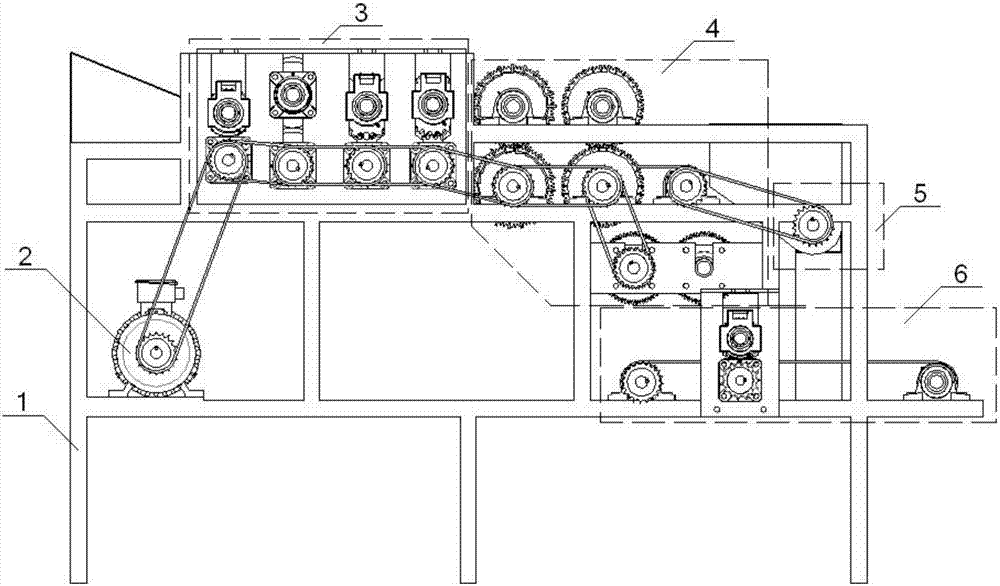

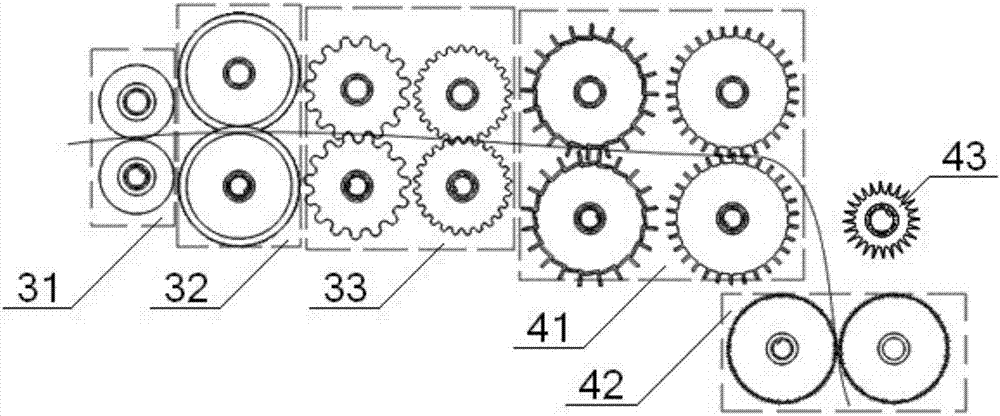

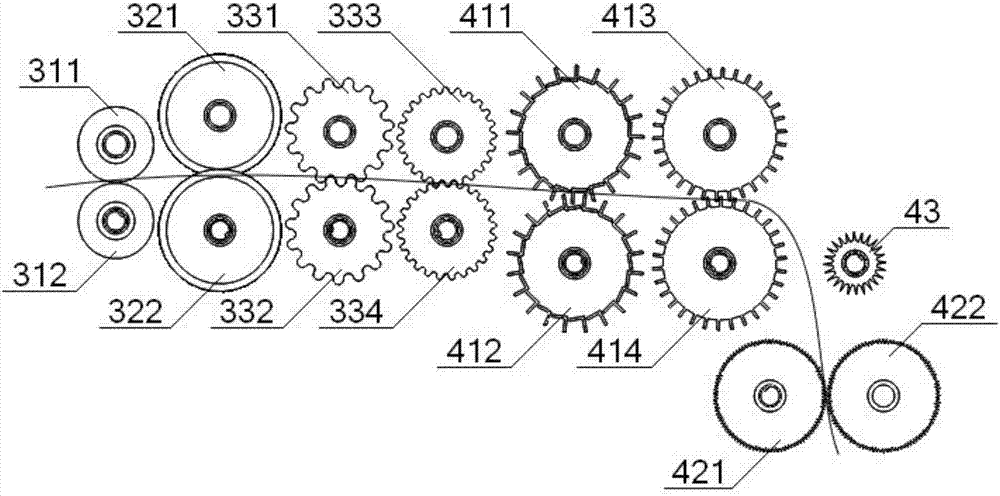

[0043] see figure 1 , a fully automatic ramie peeling machine, comprising a frame 1, a power mechanism 2, a ramie pretreatment unit 3, a hemp skin and a hemp bone separation device 4, a hemp bone output mechanism 5, and a hemp skin output mechanism 6, the hemp skin The separating device 4 is arranged on the middle part of the frame 1, the hemp skin output mechanism 6 is arranged on the bottom of the frame 1, and the ramie pretreatment unit 3 is arranged on the frame 1 and is positioned at the separating device of the hemp skin and the bone. 4 the position in front, the hemp bone output mechanism 5 is arranged on the frame 1 and is positioned at the position behind the hemp skin and the hemp bone separation device 4, and the power mechanism 2 is arranged on the bottom of the frame 1, and the power mechanism 2 and the ramie preliminary The processing unit 3 is connected, the ramie pretreatment unit 3 is connected with the hemp skin and the hemp bone separation device 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com