Cement component

A component and cement technology, applied in the direction of building materials, etc., can solve problems such as easy fracture, increase the volume of cement components, and inconvenience in volume construction, and achieve the effect of increasing impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the present invention will be specifically introduced with reference to the drawings and specific embodiments.

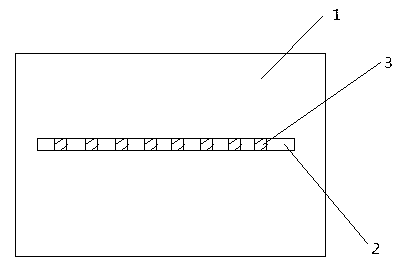

[0015] figure 1 It is a schematic diagram of a preferred implementation of the present invention. Reference figure 1 As shown, a cement component of the present invention includes: a cement layer 1; and a metal layer 2 wrapped by the cement layer 1, and a plurality of through holes 3 are opened on the metal layer.

[0016] The cement component of the present invention is formed by pouring cement slurry into a mold and then solidifying, and the metal layer of the present invention is formed in the cement component by being wrapped by the cement slurry during the cement slurry pouring. However, the present invention does not specifically limit the casting method of the cement component, nor does it limit the shape of the mold, and the specific shapes of the cement layer 1 and the metal layer 2 in the cement component. However, preferably, the shape o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com