Submersible pump

A technology of submersible pumps and water pumps, applied in pumps, pump devices, non-variable pumps, etc., can solve the problems of increasing motor load, friction, and motor burnout, and achieve the effects of reducing friction, prolonging practical life, and avoiding burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

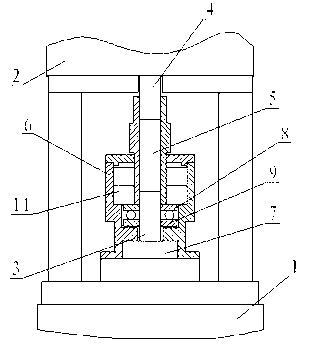

[0009] see figure 1 As shown, a submersible pump of the present invention includes a motor 1, a water pump 2 arranged on the motor 1, and a short shaft 5 coaxially connected with the power output shaft 3 of the motor 1 and the power input shaft 4 of the water pump 2 , and a hollow casing 6 arranged on the periphery of the power output shaft 3 of the motor 1, the hollow casing 6 is positioned coaxially with the motor casing by the positioning convex edge 7 that is coaxially protruded by the casing on the top of the motor 1 and the power output shaft 3 For solid connection, the hollow shell 6 is provided with a ring platform 8 , and a thrust bearing 9 is press-fitted between the upper end surface of the ring platform 8 and the short shaft 5 .

[0010] A rubber sealing ring 11 is sleeved between the hollow casing 6 on the upper part of the thrust bearing 9 and the short shaft 5 .

[0011] A temperature control switch (not shown) capable of controlling the power switch is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com