Mine round-link chain split ring quick release mechanism

A mine-used round link chain and split ring technology, applied in the direction of shackles, etc., can solve the problems of inability to disassemble, corrosion of connecting bolt threads, etc., and achieve the effect of simple and fast installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

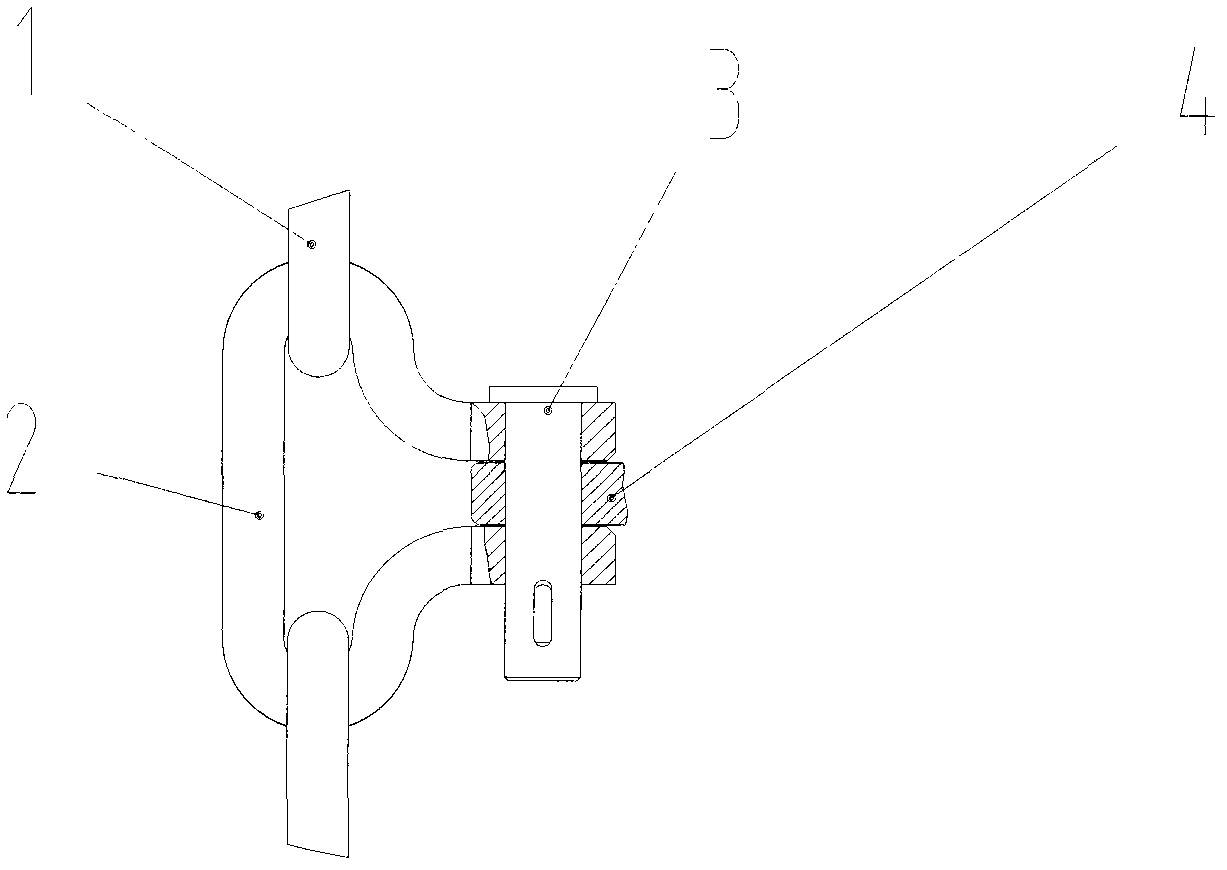

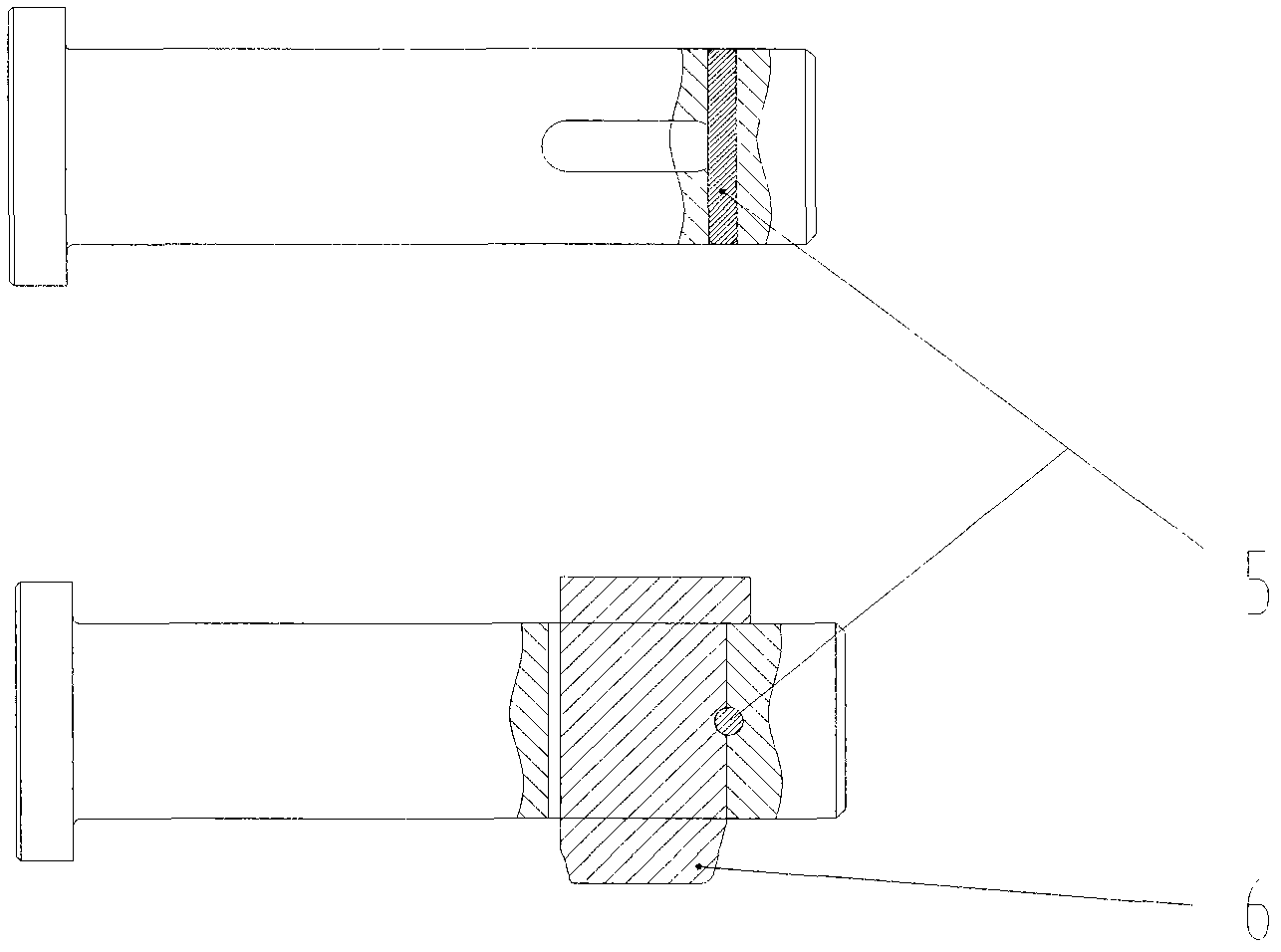

[0008] Depend on figure 1 and figure 2 It can be seen that split ring (2) is arranged on the ring chain group (1) of the present invention, split ring (2) is locked by quick release pin (3), and quick release pin (3) is formed by pin (5) and flat pin (6) Fix and lock the split ring (2), first install the pin (5) on the quick release pin (3), insert the quick release pin (3) into the split ring (2) and the connector (4) Then install the flat pin (6) on the quick release pin (5), the groove of the flat pin (6) is stuck on the pin (5), and the split ring (2) is locked, and the split ring ( 2), knock the protruding part of the flat pin (6) to make it withdraw and take off the quick release pin (3) to complete the disassembly of the split ring (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com