Electronic whiteboard equipment automatic pixel mapping method

An electronic whiteboard and pixel mapping technology, applied in the direction of electronic digital data processing, instruments, data processing input/output process, etc., can solve the problems of collection errors, interference spot 5, positioning spot 8 and insufficient light sensitivity, and improve accuracy , Improve the effect of collection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

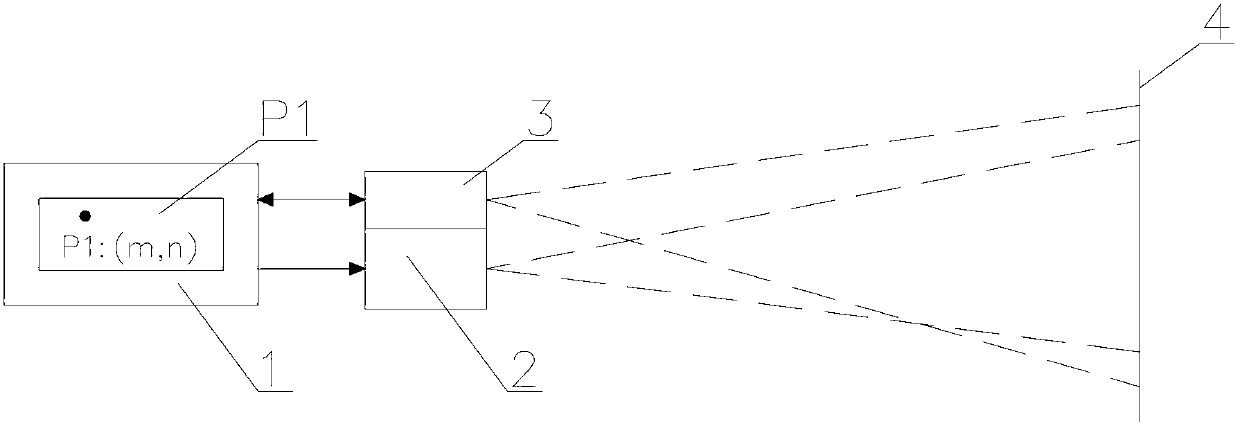

[0031] An automatic pixel mapping method for an electronic whiteboard device, comprising the following steps:

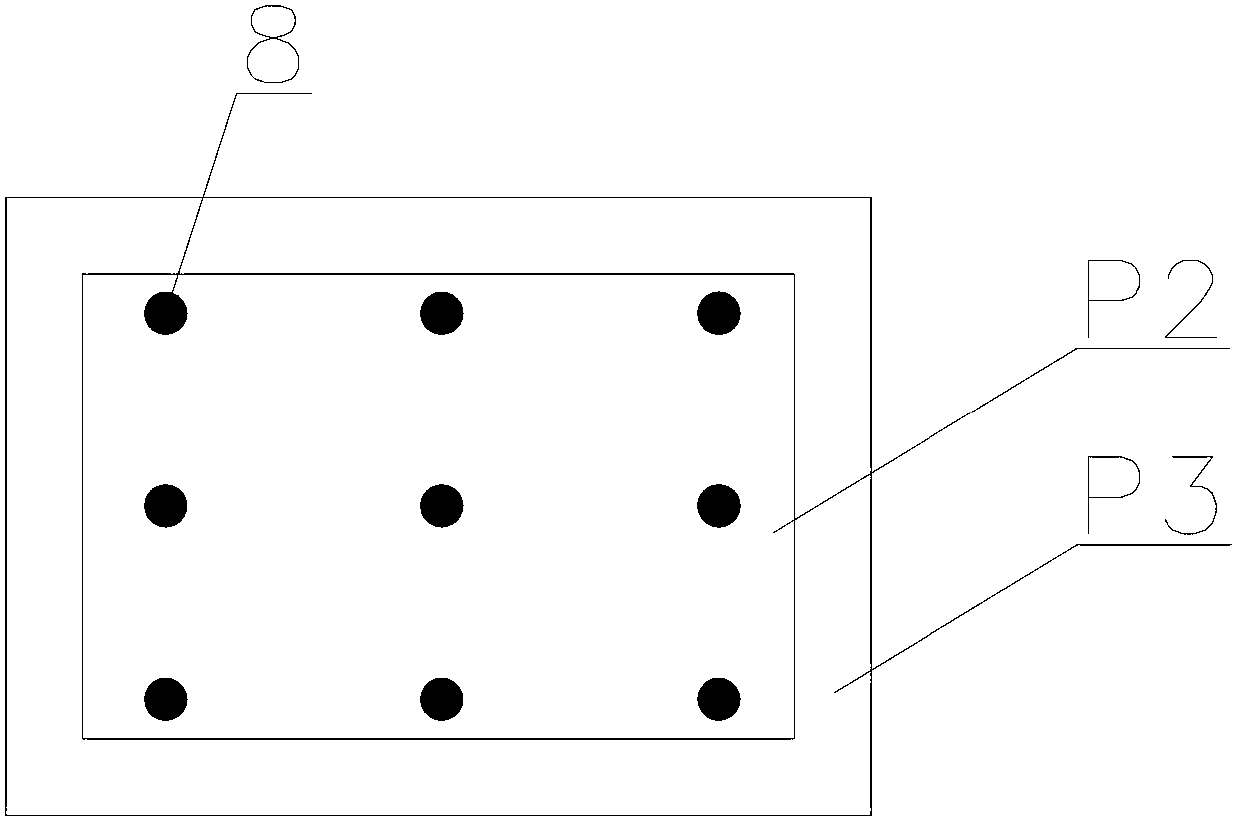

[0032] (1) if Figure 5 As shown, the camera plane P3 is divided into m units 6 by a rectangular grid with a unit length of n=3 pixels, each unit 6 includes n×n=3×3=9 pixel points 7, and the number of cycles k= 1;

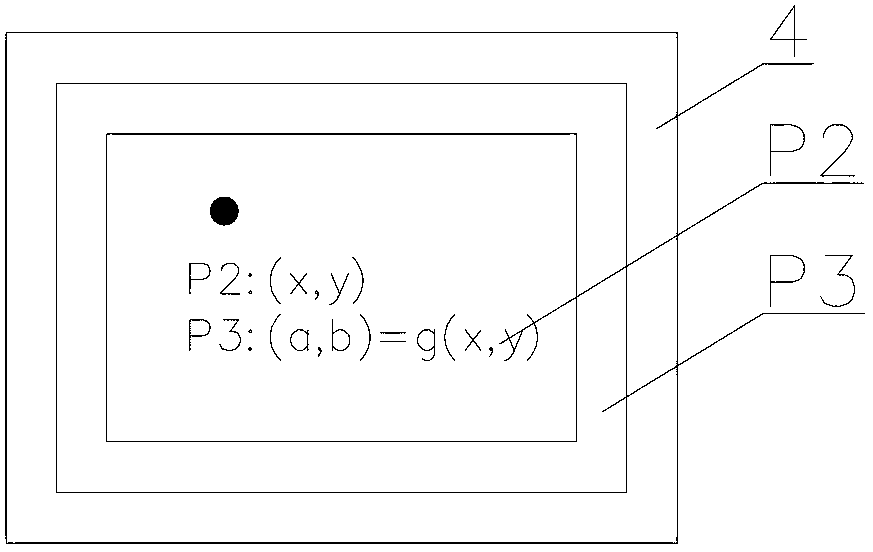

[0033] (2) Projecting a number of positioning light spots 8 on the projection plane P2 and the camera plane P3;

[0034] (3) Position and collect the image of the camera plane P3 on the j=kth pixel of all m units, collect the grayscale / brightness value of the positioning spot on the m pixel point, and set the grayscale / brightness value to Calculate the center of gravity value G of the positioning spot image on the pixel point of the value ij , store the center of gravity value;

[0035] (4) k=k+1, judge whether k≤n×n is true, if the judgment ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap