Process for production of euglena containing wax ester at high content, and process for production of wax ester

A production method and manufacturing method technology, applied in the direction of biochemical equipment and methods, single-cell algae, fermentation, etc., can solve the problems of low production, food shortage, etc., and achieve the effect of improving environmental problems and increasing energy self-sufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

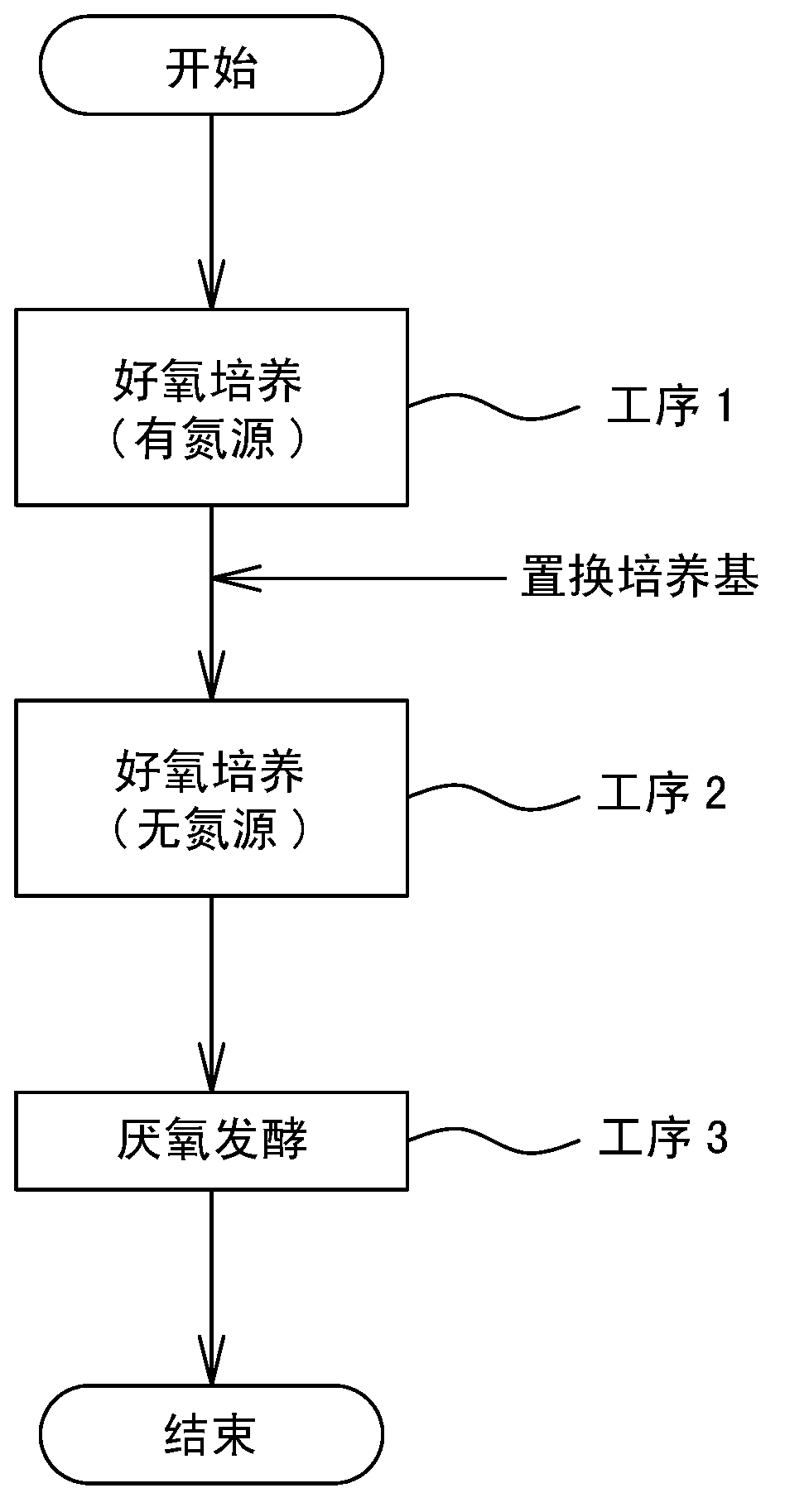

[0069] according to figure 1 , the first embodiment of the production method of the euglena genus algae rich in wax esters according to the present invention will be described.

[0070] The production method comprises: step 1 (equivalent to the first step), carrying out aerobic culture of euglena algae with a medium added with a nitrogen source; step 2 (equivalent to the second step), replacing it with a nitrogen source-free medium Carry out aerobic culture in the culture medium; Step 3 (equivalent to the 3rd step), carry out anaerobic treatment, carbohydrate is fermented into wax ester.

[0071] First, the cultivation of the algae of the genus Euglena in step 1 can also be carried out by blowing air into the medium as a carbon dioxide source, but it is preferable to blow carbon dioxide gas into the medium in order to increase the cultivation efficiency.

[0072] That is, since oxygen is contained in the atmosphere or carbon dioxide gas, aerobic culture is performed.

[0073...

no. 2 Embodiment approach

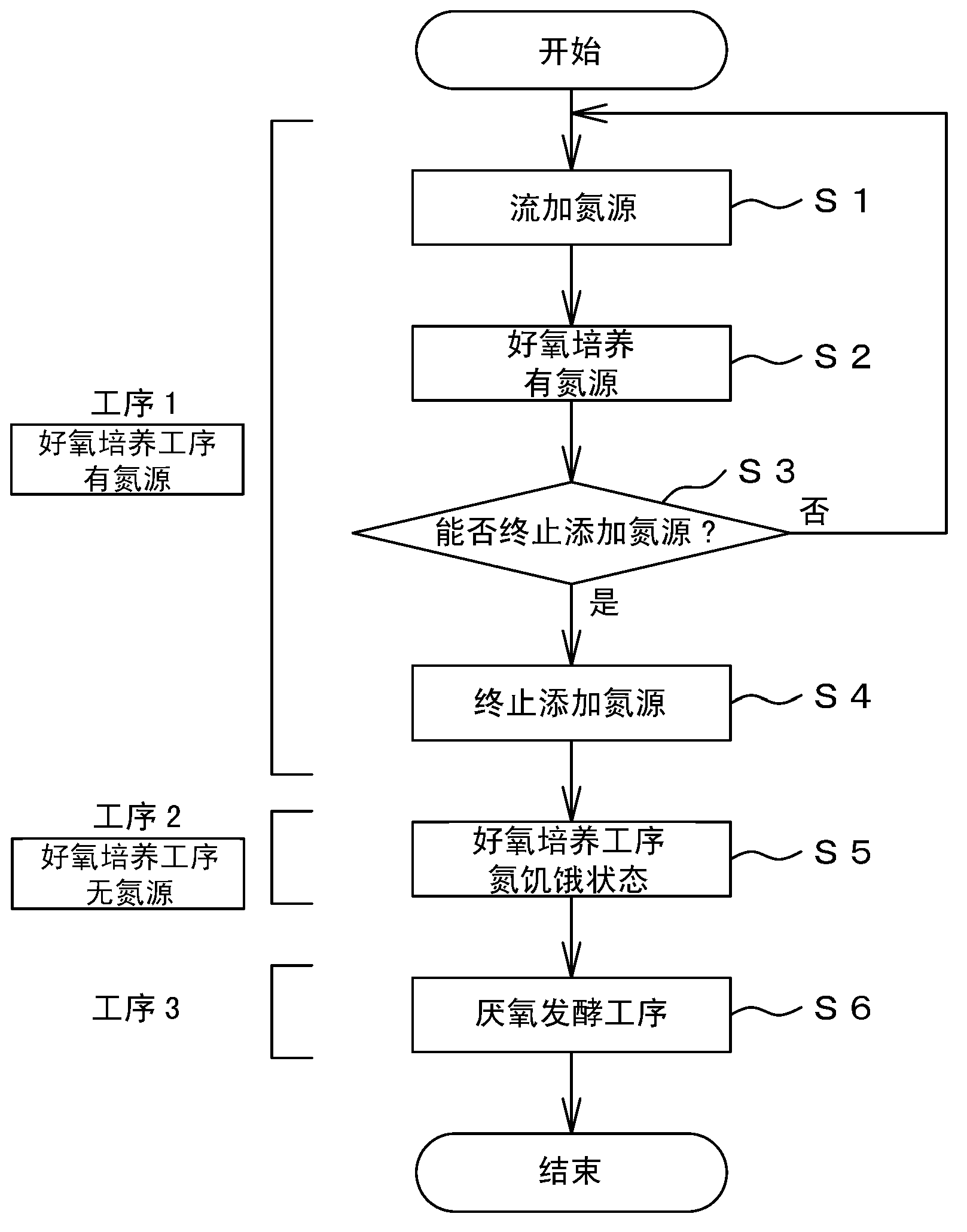

[0093] according to figure 2 , the second embodiment of the production method of the euglena genus algae rich in wax esters according to the present invention will be described.

[0094] It should be noted that, since the medium composition, culture conditions, etc. are the same as those of the first embodiment, the same description will be omitted, and only the differences will be described.

[0095] In the aerobic culture step in Step 1, a medium obtained from the modified Cramer-Myers medium in Step 1 of the first embodiment from which a nitrogen source was removed is used.

[0096]That is, in the initial stage, the aerobic cultivation of the algae of the genus Euglena is started with a medium that does not contain a nitrogen source.

[0097] In step 1, first, in step S1, a nitrogen source is added to the culture medium inoculated with algal bodies of the genus Euglena.

[0098] Then, aerobic cultivation is carried out in step S2.

[0099] Next, in step S3, it is determ...

Embodiment

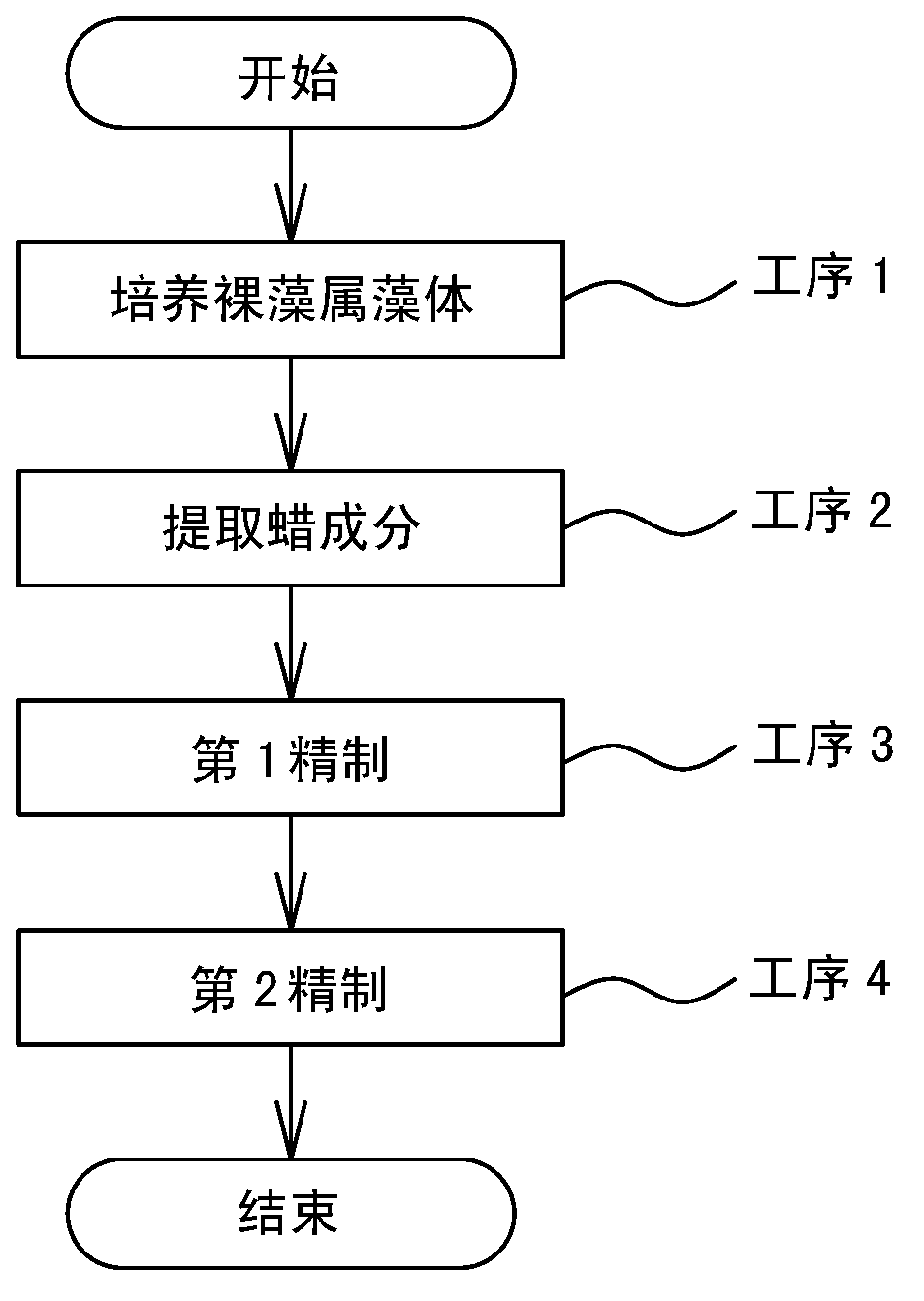

[0122] (About the production method of euglena algae rich in wax esters)

[0123] Next, the wax ester-rich algae of the genus Euglena according to the present invention will be specifically described by showing an example.

[0124] In this example, Euglena graclilis Z strain was used.

[0125] The medium was modified by modifying Cramer-Myers medium ((NH 4 ) 2 HPO 4 1.0g / L, KH 2 PO 4 1.0g / L, MgSO 4 ·7H 2 O 0.2g / L, CaCl 2 2H 2 O 0.02g / L, EDTA·2Na 0.05g / L, Fe 2 (SO 2 ) 3 ·7H 2 O 3mg / L, MnCl 2 4H 2 O 1.8mg / L, CoSO 4 ·7H 2 O 1.5mg / L, ZnSO 4 ·7H 2 O 0.4mg / L, Na 2 MoO 4 2H 2 O 0.2mg / L, CuSO 4 ·5H 2 O 0.02g / L, thiamine hydrochloride (vitamin B 1 ) 0.1mg / L, cyanocobalamin (vitamin B 12 ), (pH5.5)) were prepared by autoclaving.

[0126] (Process 1: Aerobic cultivation)

[0127] After 880 ml of the prepared medium was put into a shaking culture bottle with a capacity of 1 L, the seed algae of Euglena algae were inoculated with an initial concentration of abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com