paint house

A technology for a paint spray booth and a main body is applied in the field of paint spray booths, which can solve the problems of physical injury of workers, low efficiency and precision of manual painting, and achieve the effects of low manufacturing cost, ensuring no dead ends in spraying, and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

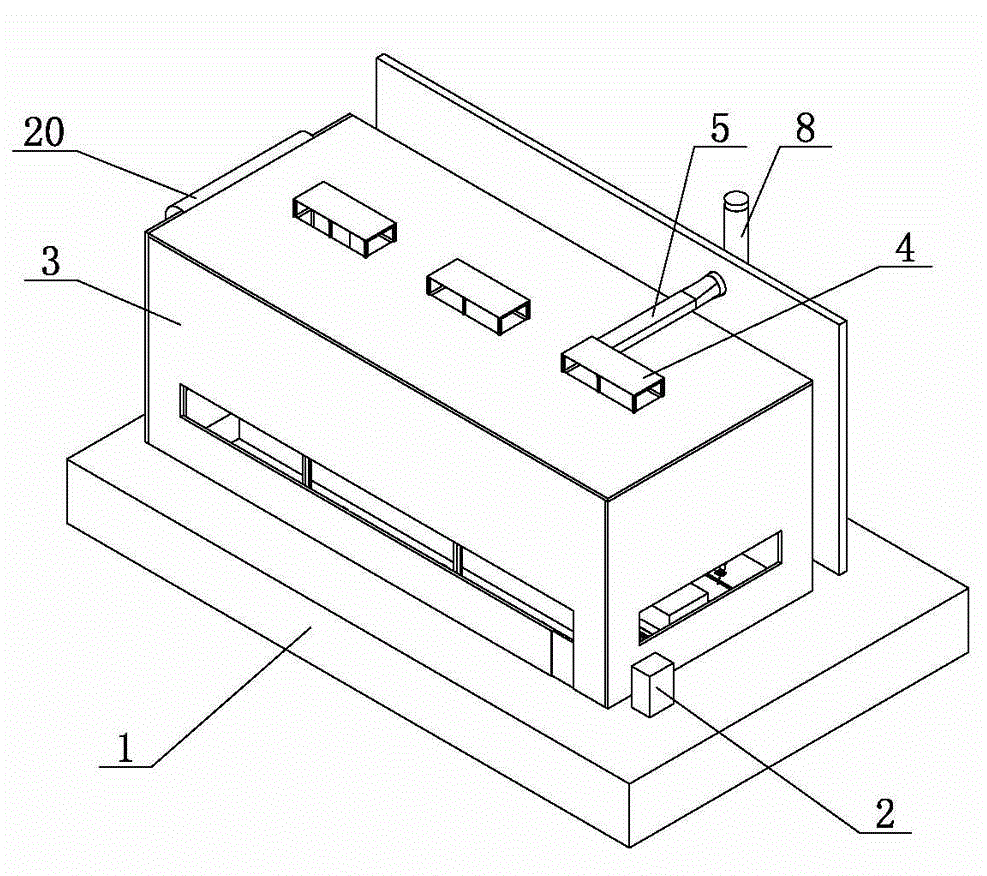

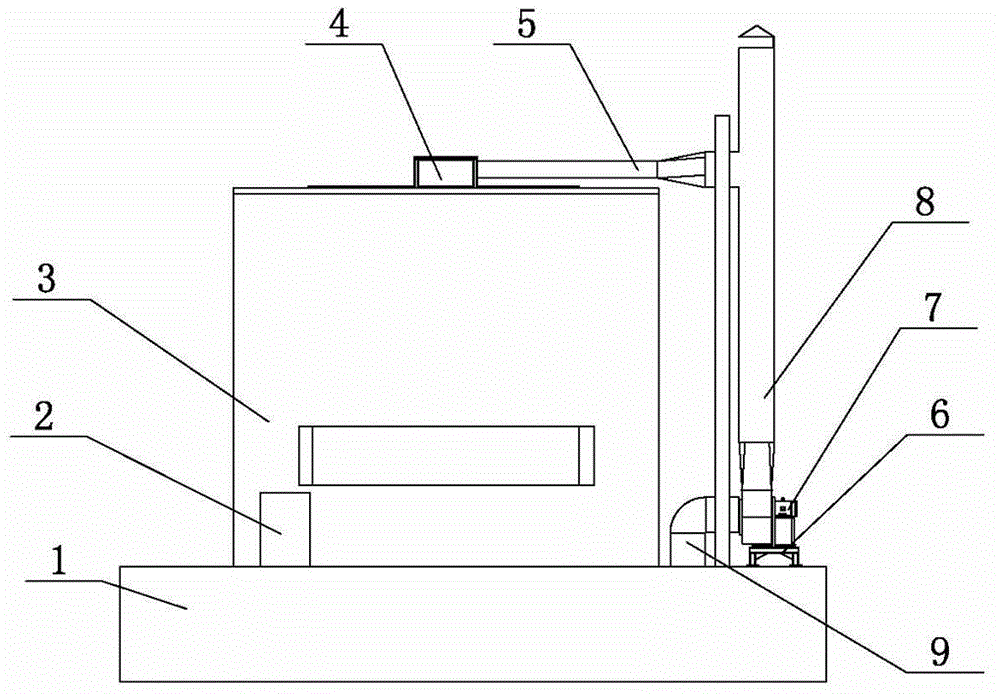

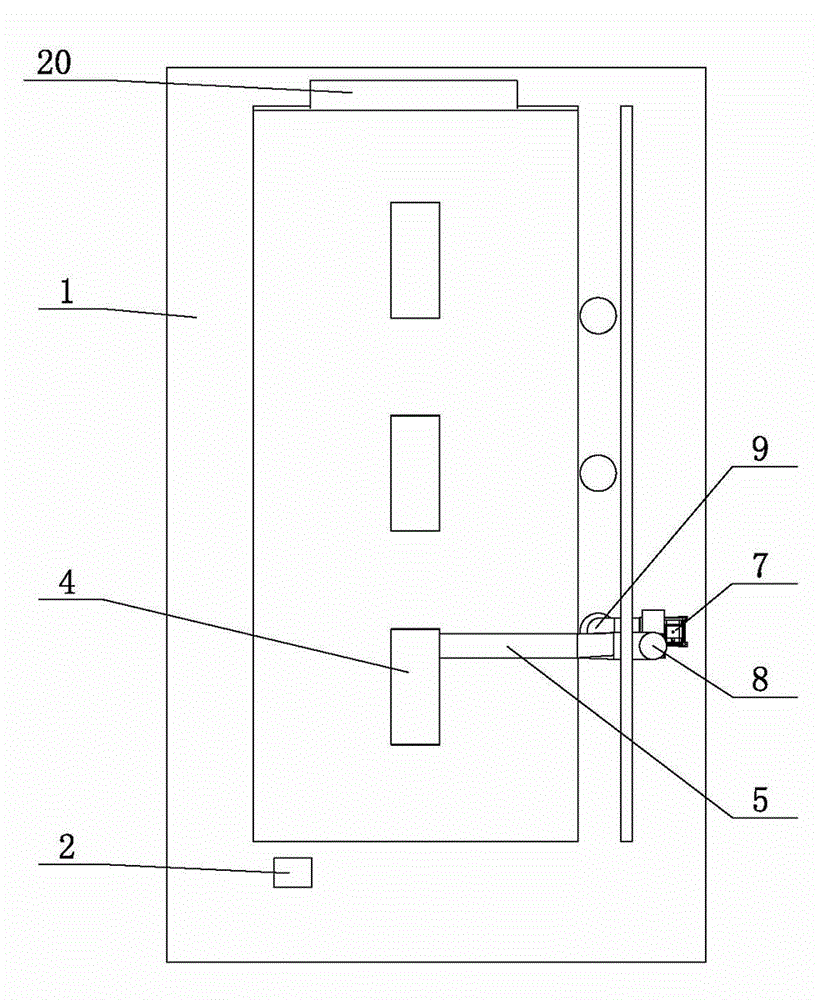

[0009] The spray booth of the present invention includes a main body 3 of the spray booth, and a door 20 is provided on the main body 3 of the spray booth. The door 20 may be a rolling door. The bottom of the main body 3 of the spray booth is provided with a foundation 1 . The machine head moving mechanism is installed in the main body 3 of the painting room. The machine head moving mechanism can drive the machine head to move horizontally or vertically in the horizontal plane. Lifting mechanism 27 is installed on the head moving mechanism, and the lower end of lifting mechanism 27 is installed the machine head. like Figure 12 to Figure 14 As shown, the machine head includes a paint canister 49 and a connecting sleeve 60; the paint canister 49 is connected to the connecting sleeve 60. Servomotor 50 is installed in connecting sleeve 60, and connection support member 51 is installed on the output shaft of servomotor 50, and suspension mechanism 61 is installed on connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com