Patents

Literature

33results about How to "Smooth traverse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

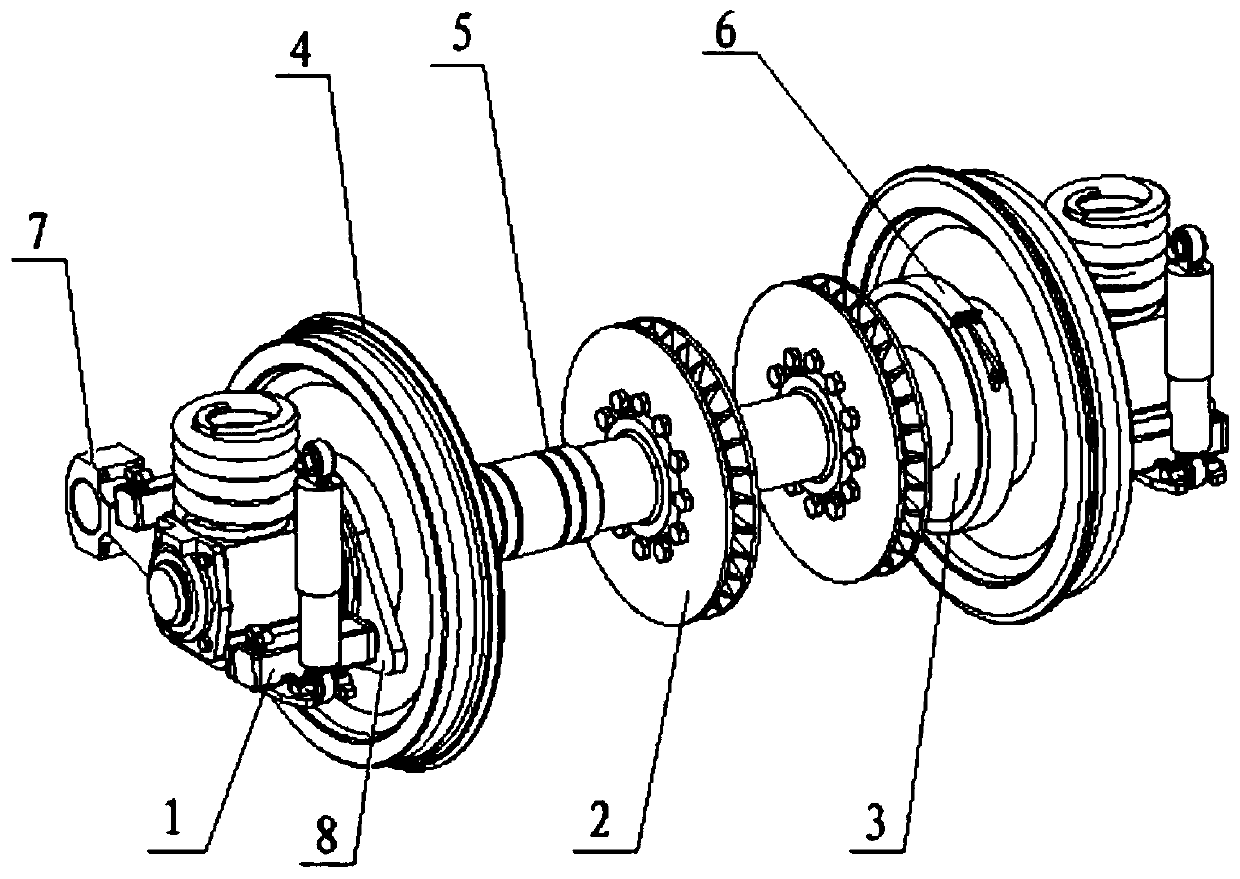

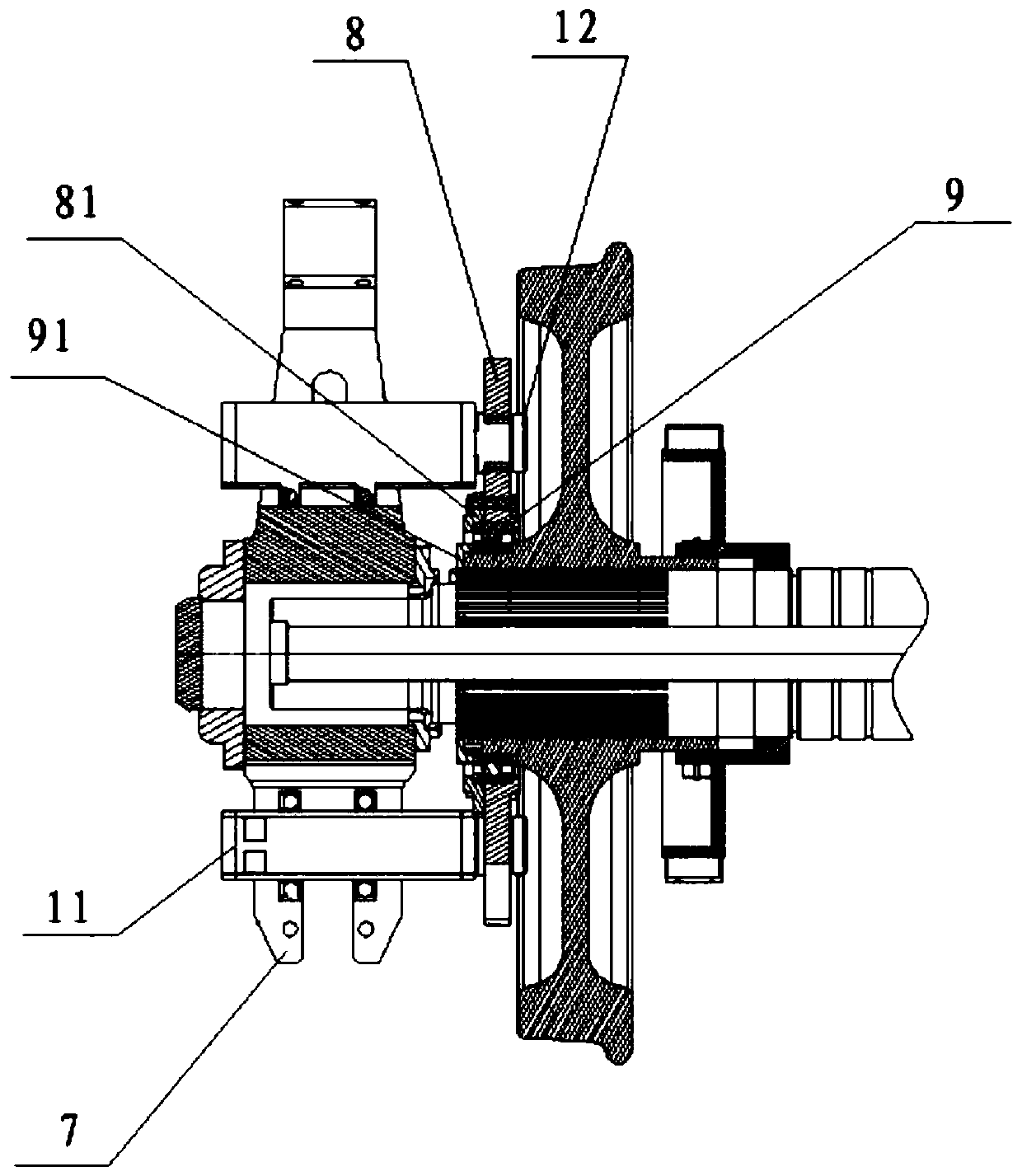

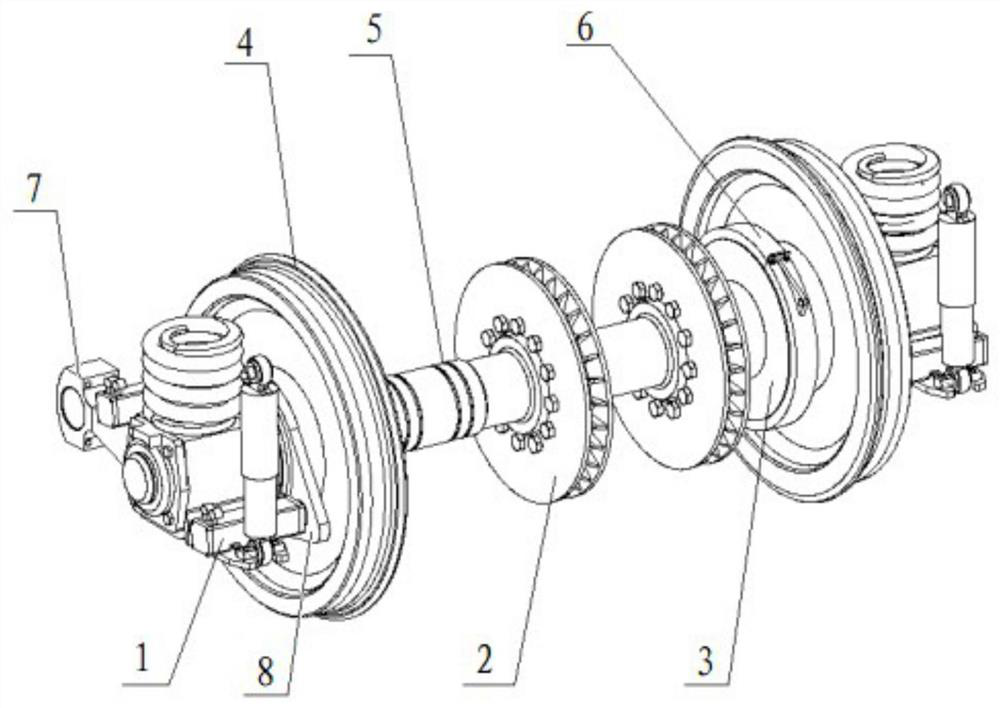

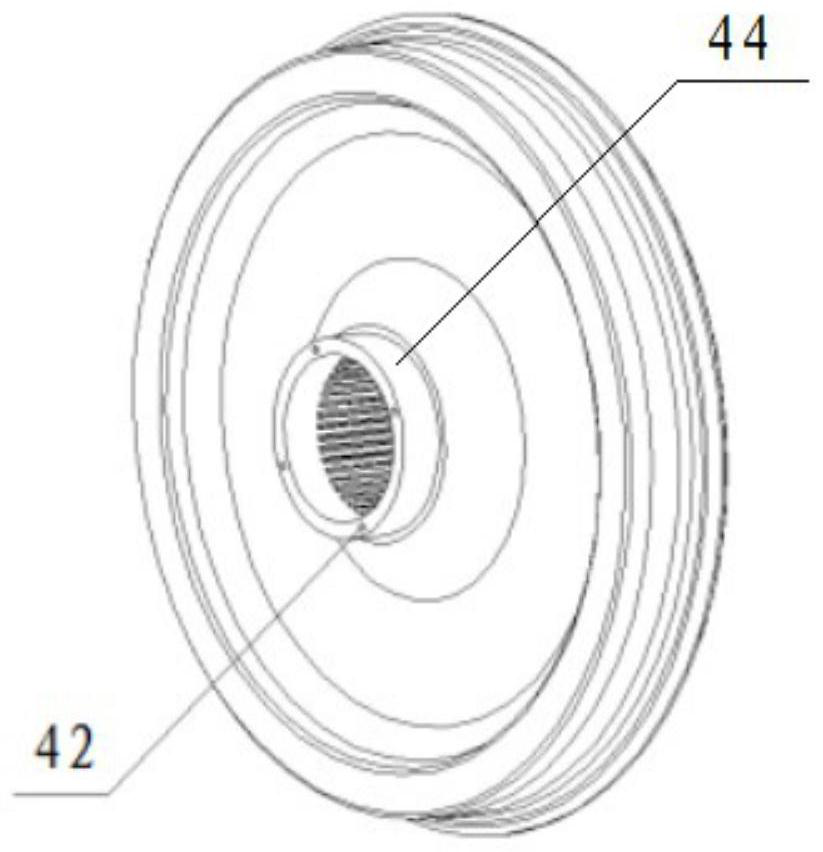

Gauge-changeable wheel set and gauge-changeable bogie

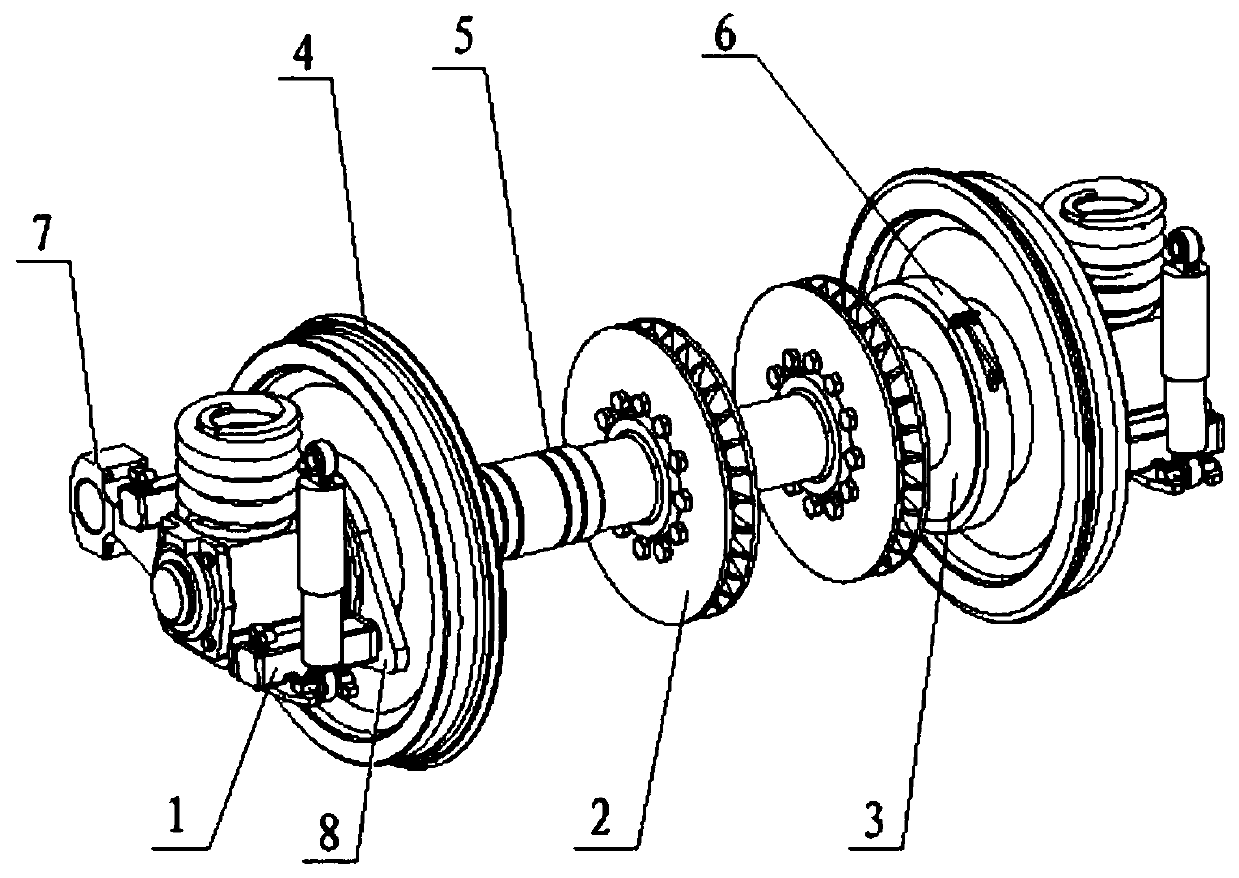

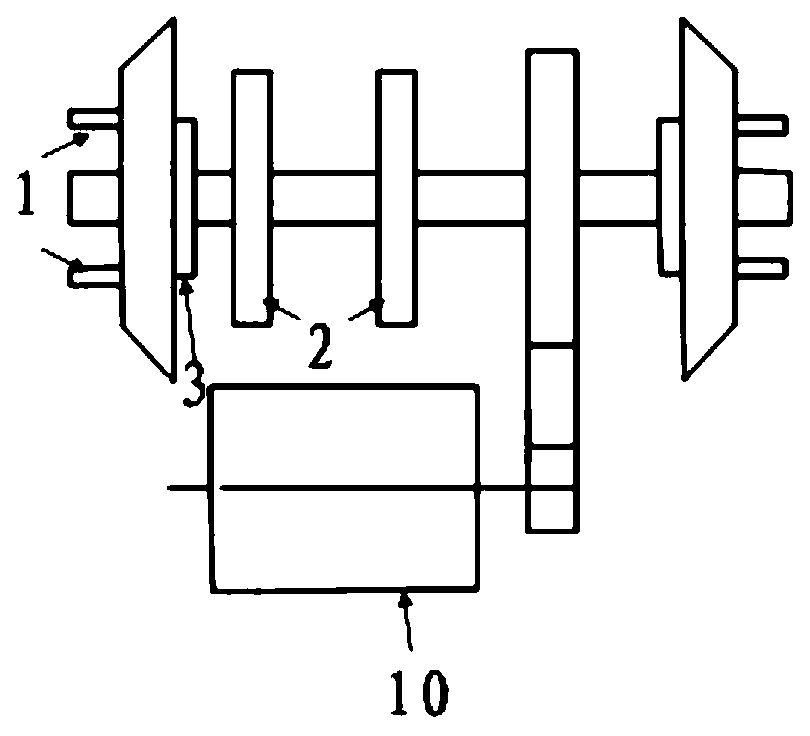

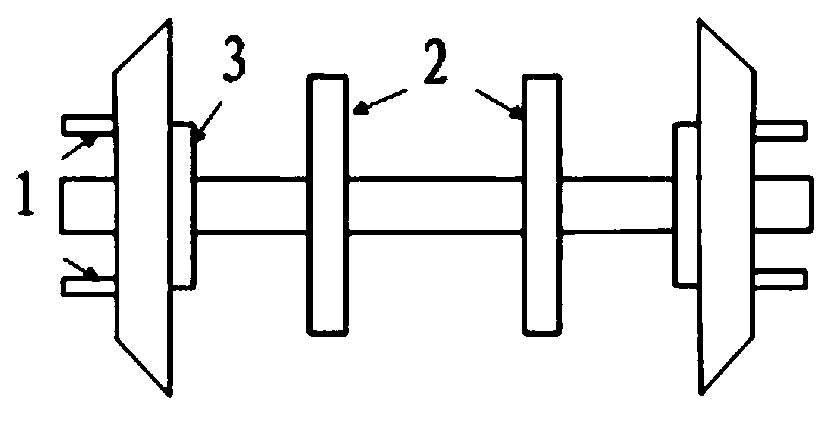

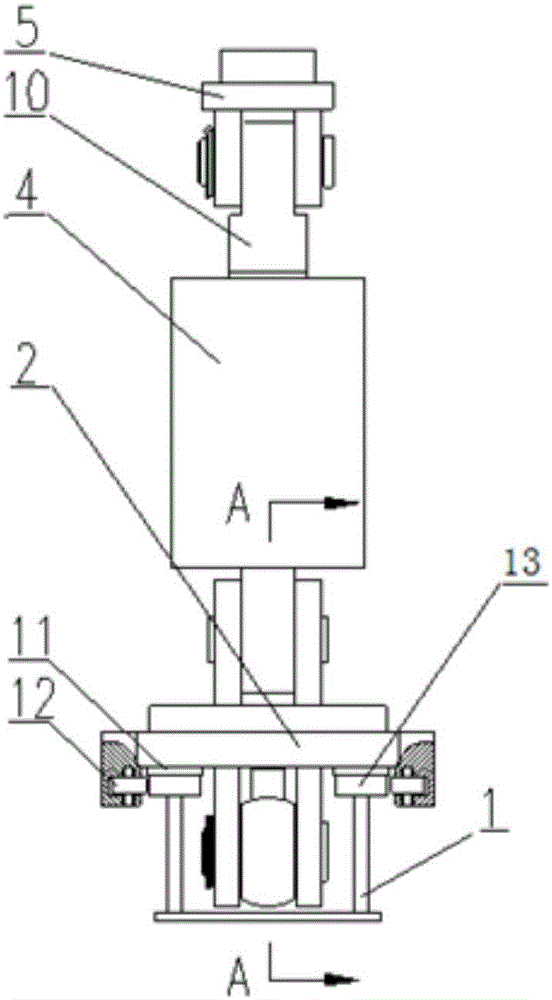

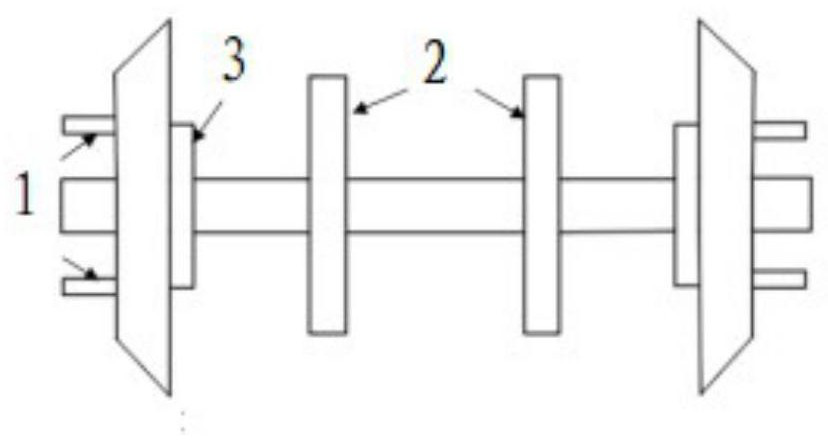

The invention relates to the field of rail vehicle gauge changing, and discloses a gauge-changeable wheel set and a gauge-changeable bogie; the gauge-changeable wheel set comprises wheels, an axle, locking mechanisms and transverse driving mechanisms; the wheels are connected with the axle through splines, and two ends, located outside the wheels, of the axle are supported in axle boxes respectively; the locking mechanisms are arranged on the inner sides of the wheels respectively, each locking mechanism comprises a traction electromagnet, each traction electromagnet comprises a traction coiland a movable iron core driven by the traction coil to move, a plurality of locking holes are formed in hubs on the inner sides of the wheels at intervals in an axial direction, and the movable iron cores can extend into or leave the locking holes to achieve locking or unlocking of the wheels; the transverse driving mechanisms are arranged on the outer sides of the wheels correspondingly and fixedto the axle boxes; each transverse driving mechanism comprises an electric cylinder; extending ends of the electric cylinders are used for pushing or pulling the unlocked wheels, such that gauge changing of the wheels is achieved. Abrasion between wheel axles can be reduced, the gauge changing reliability is improved, and the gauge changing efficiency is improved.

Owner:CRRC QINGDAO SIFANG CO LTD +1

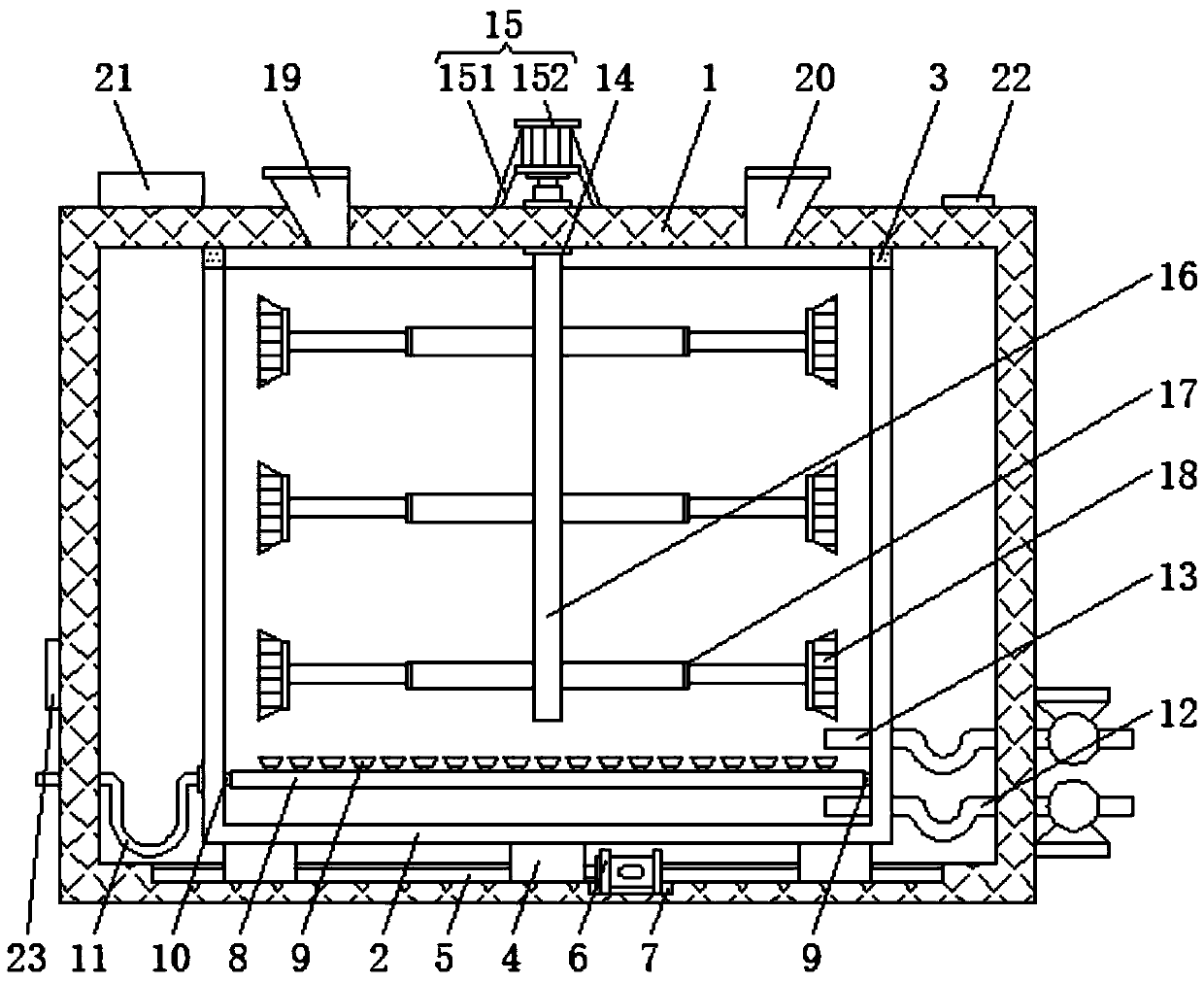

Stirring device used for circulating membrane contact bioreactor for river water

PendingCN109626560AWell mixedEfficient removalSpecific water treatment objectivesBiological treatment apparatusReciprocating motionEngineering

The invention discloses a stirring device used for a circulating membrane contact bioreactor for river water, and relates to the technical field of MBR membrane bioreactor wastewater treatment devices. The stirring device comprises a box, a stirring barrel is arranged in the box, the upper surface of the stirring barrel is fixedly connected with a seal piece, and the upper surface of the seal piece is in overlapping connection with the upper surface of the inner wall of the box. The lower surface of the stirring barrel is fixedly connected with a plurality of sliders, and the sliders are slidably connected to first sliding grooves in the lower surface of the inner wall of the box. According to the stirring device used for the circulating membrane contact bioreactor for the river water, thestirring barrel can move relative to a stirring rod and a stirring device body, and accordingly, raw materials at the corners in the stirring barrel can be sufficiently stirred and mixed; because theinner wall of the stirring barrel can make contact with a scraper blade in the reciprocating process of the stirring barrel, under the action of the scraper blade, sticky materials adhering to the inner wall of the stirring barrel can be effectively removed, and the work efficiency of workers is improved.

Owner:上海万江环境科技有限公司

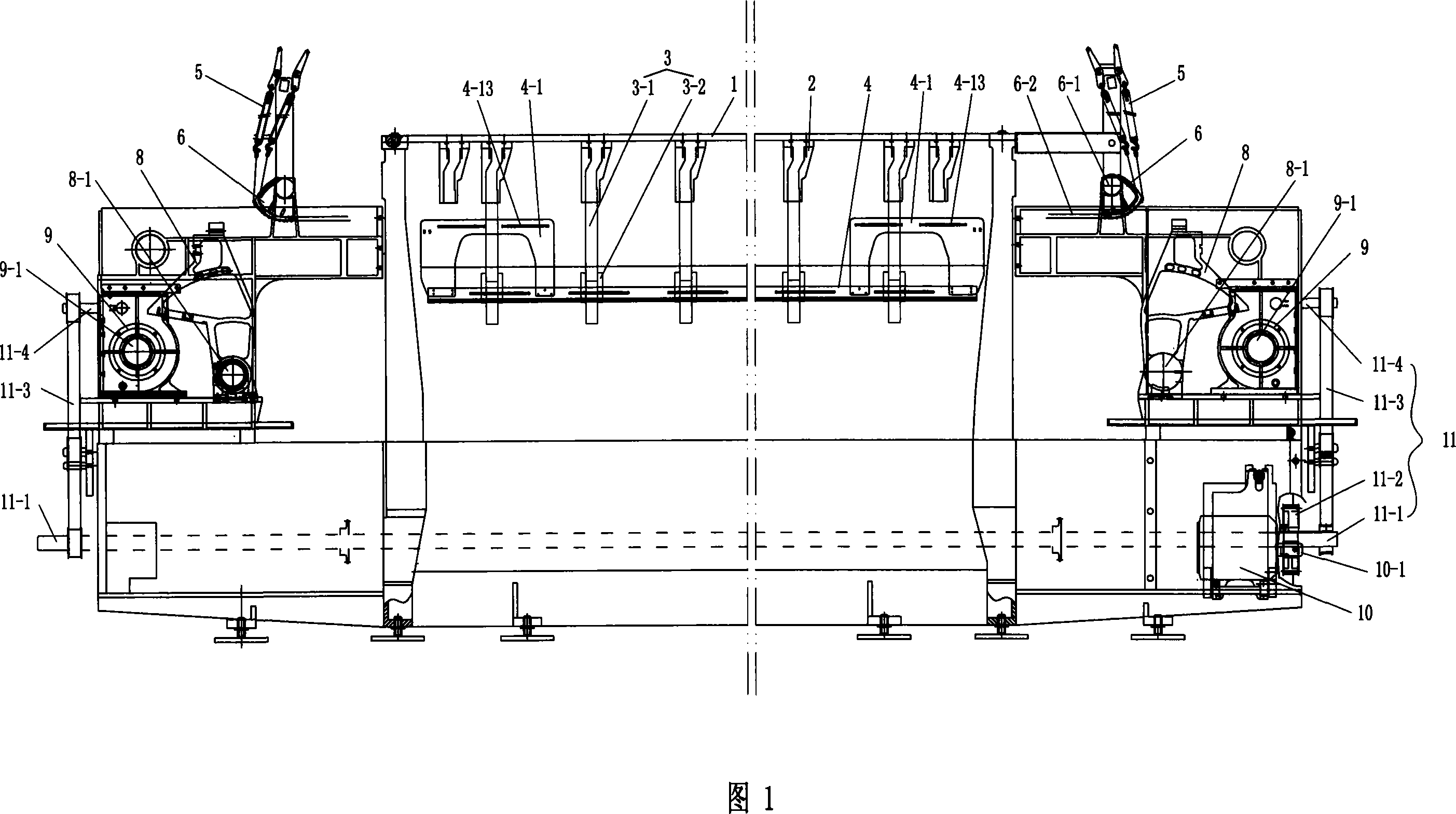

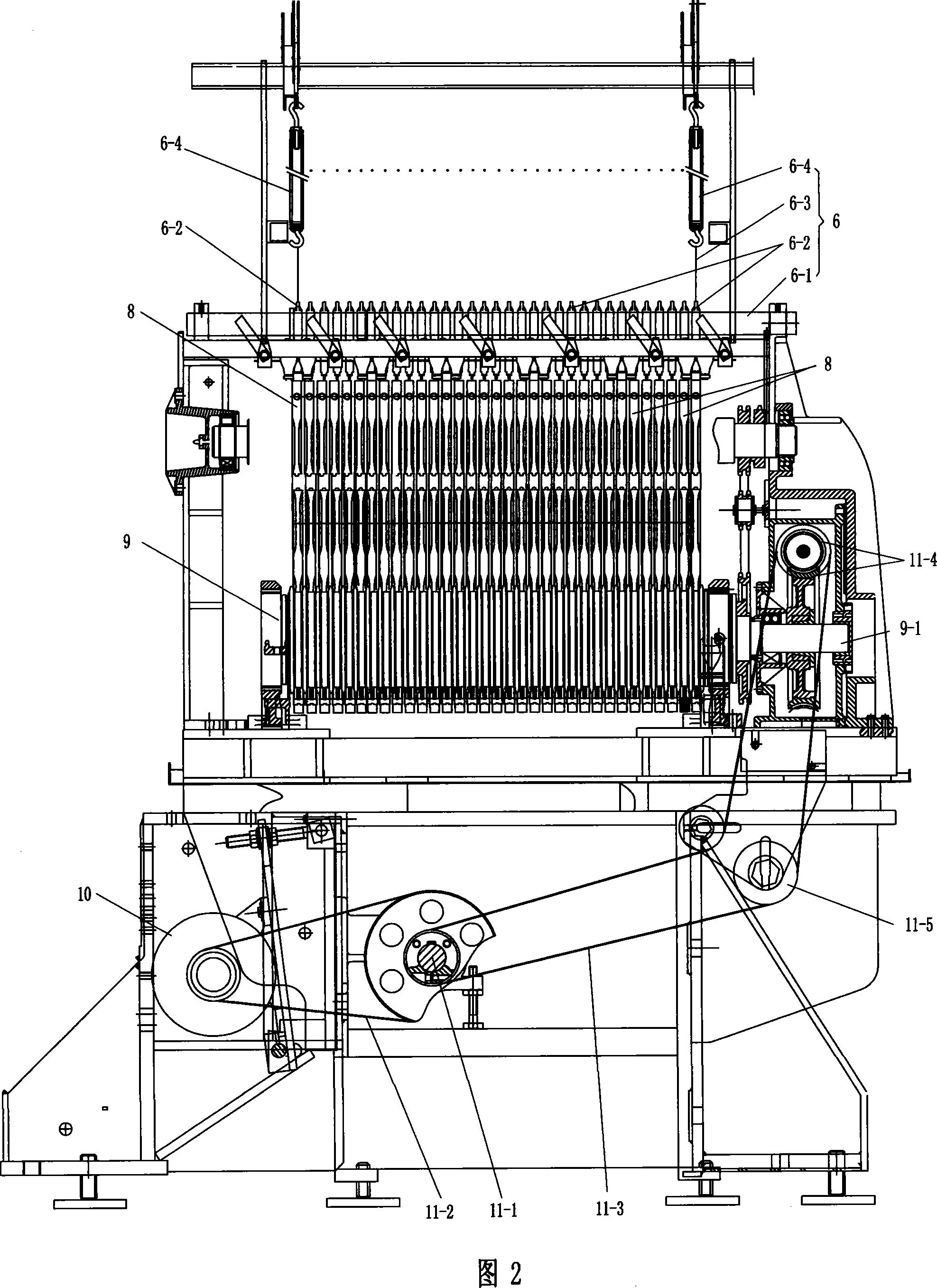

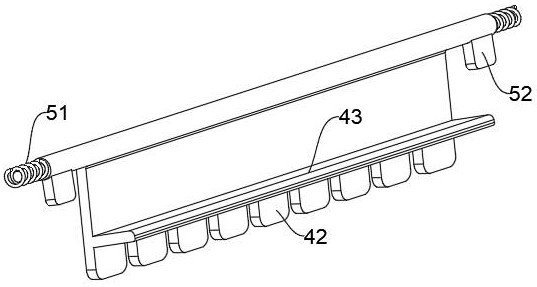

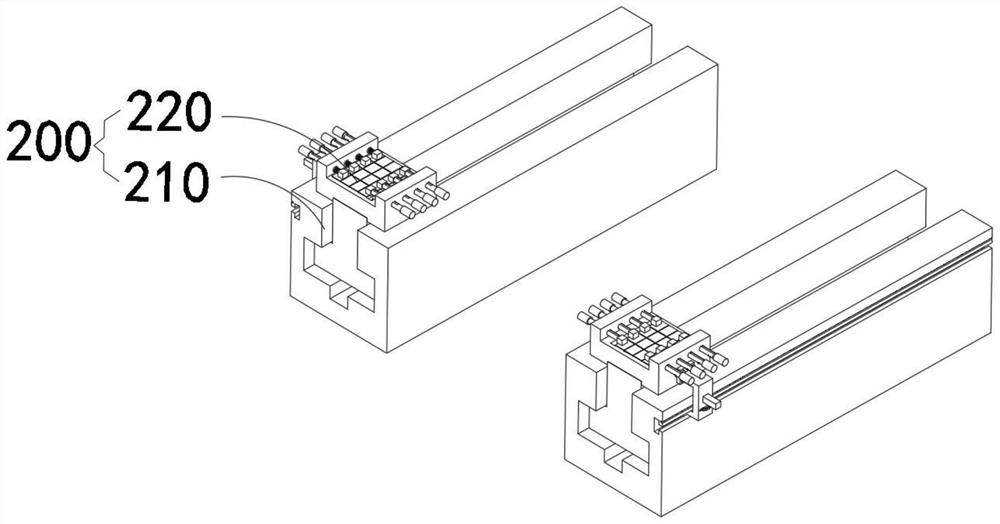

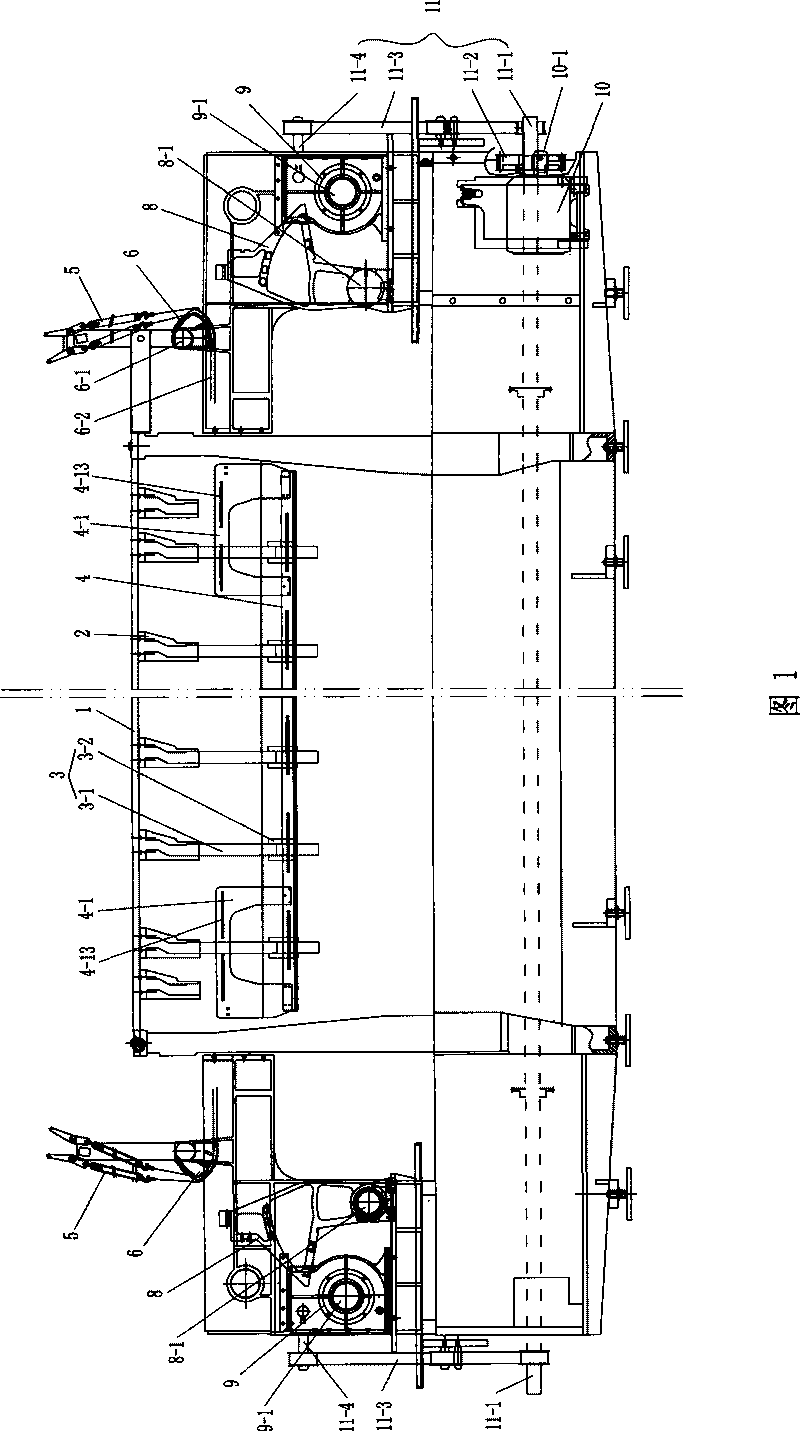

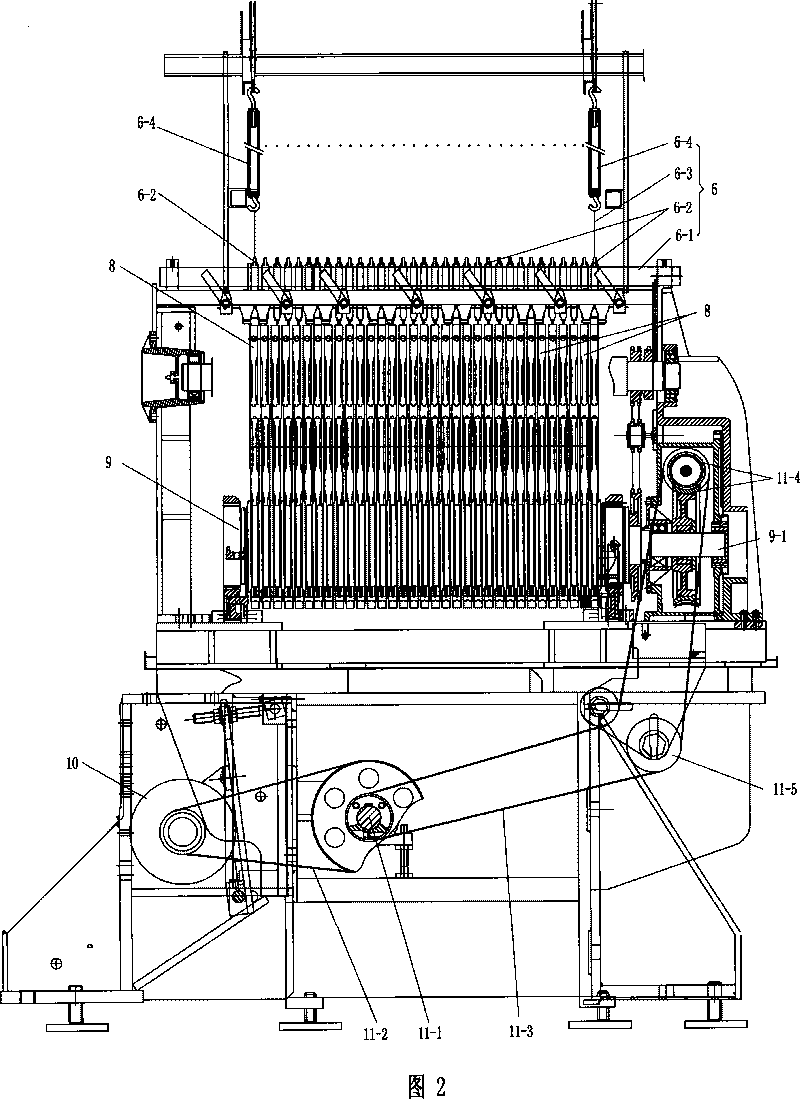

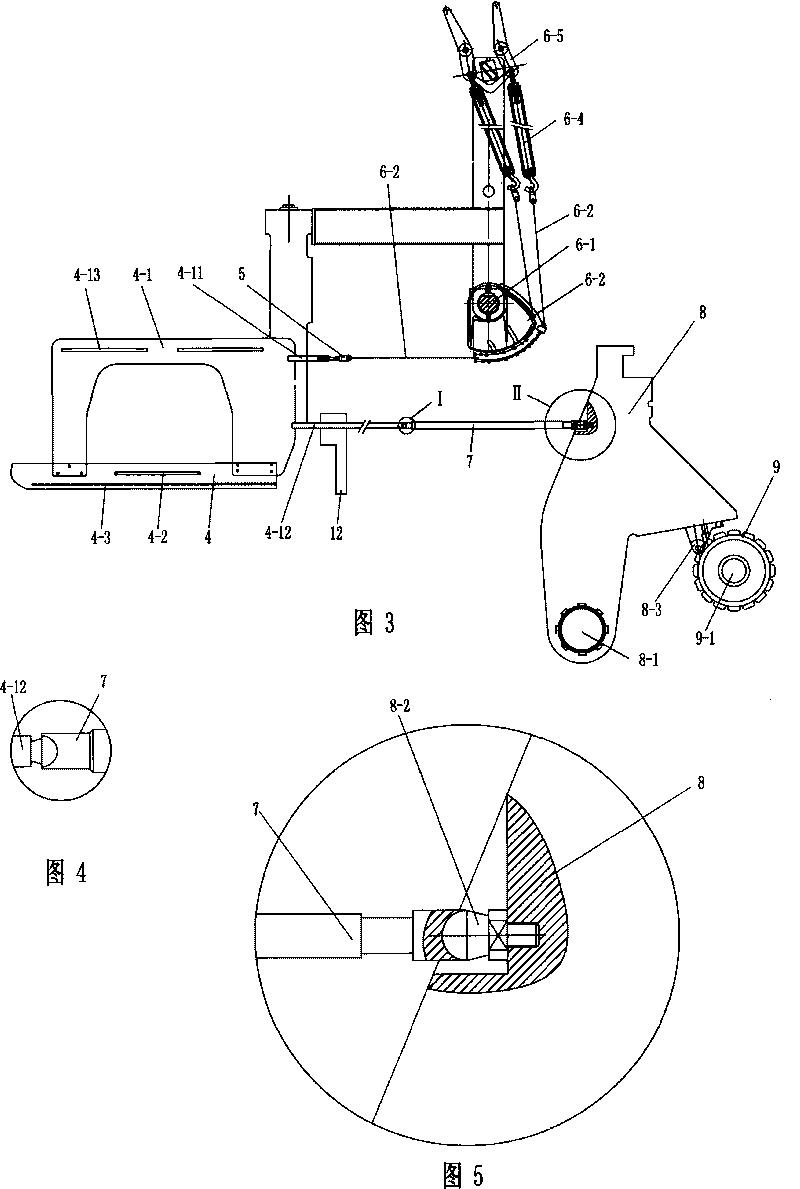

Warp loom guide bar assembly

InactiveCN101177835AThe bar moves smoothlyAccurate locationWarp knittingElectric machineryWarp knitting

The invention relates to a guide bar assembly of a warp knitting machine, comprising a tension frame support, a guide bar fixing frame, guide bars, figure knitting drums and a motor. The figure knitting drum is two and respectively arranged at the left and the right side of a machine frame; a rocking arm shaft is also positioned at the left and the right side of the machine frame respectively; the guide bars are divided into two groups; the rocking arm shafts are provided with rocking arms that are corresponding to one group of guide bars; main mandrils are connected to the rocking arms, and the guide bars are connected with the corresponding main mandrils and the rocking arms are propped in motion by mutually corresponding figured pattern card chains, which are of the same side and are on the figure knitting drums; the left and the right of the machine frame are provided with a guide bar resetting mechanism respectively; a motor promotes the two figure knitting drums to rotate through a transmission mechanism. The left side and the right side of the machine frame in the invention are provided with the figure knitting drums; the guide bars, which are divided into two groups, are steel sheet guide bars, and can meet the requirement for complex structure and figures. The guide bars of the invention can traverse stably and accurately, and have good linearity.

Owner:孙嘉良

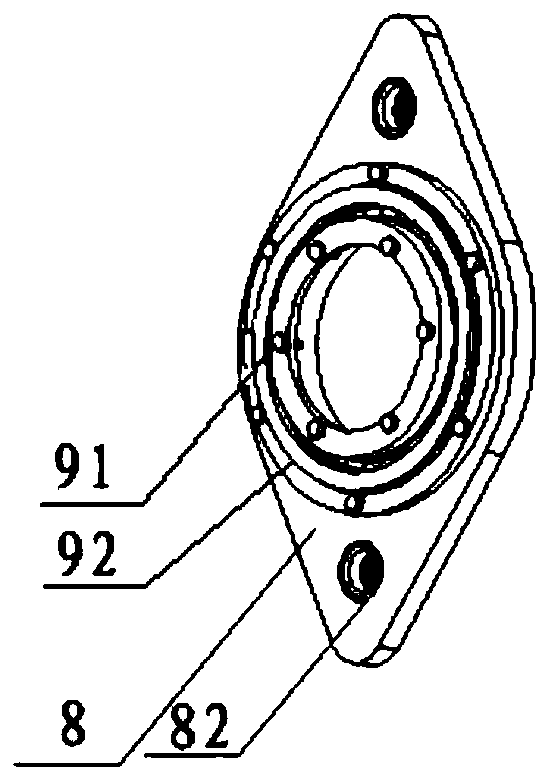

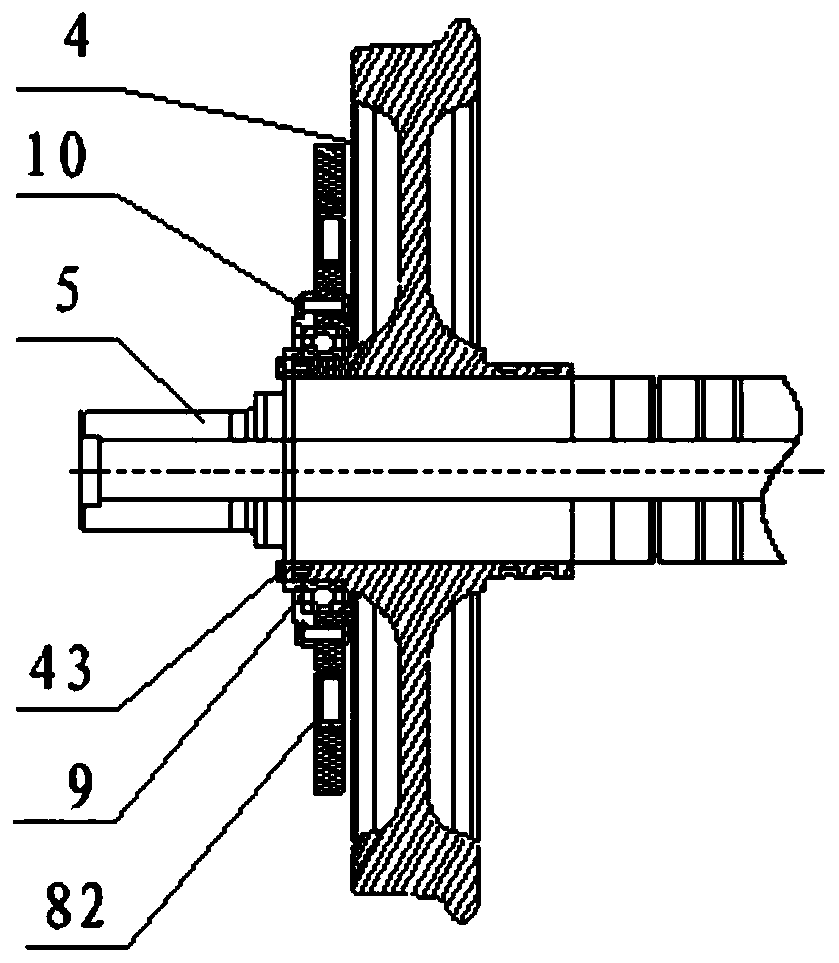

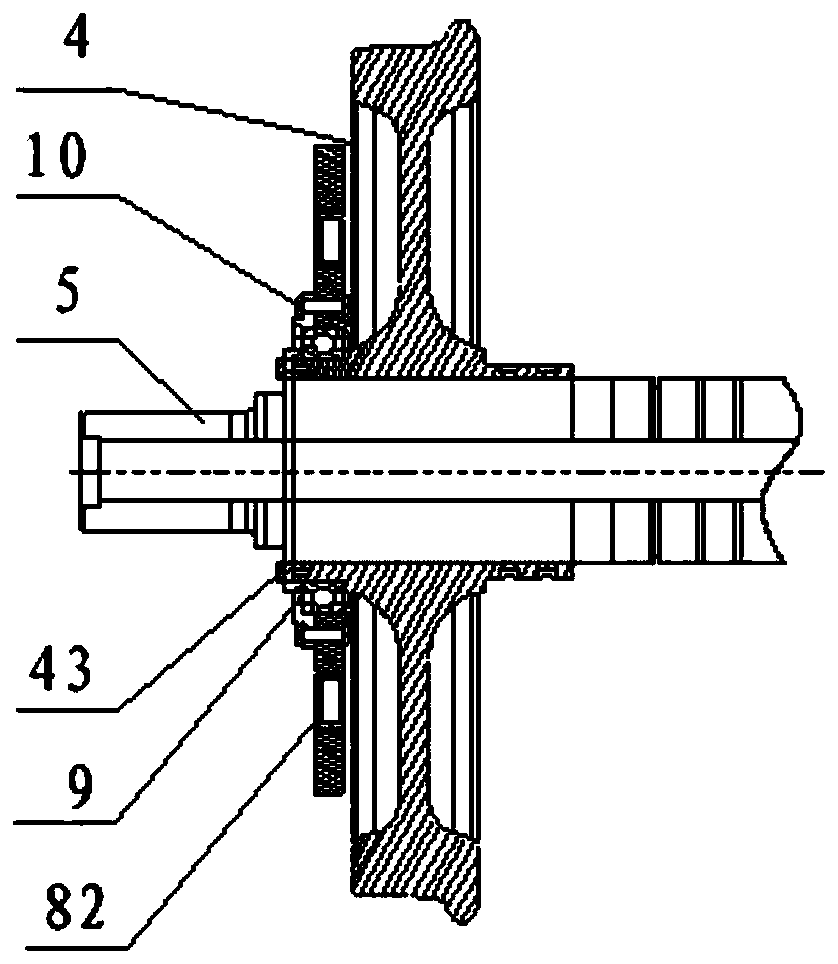

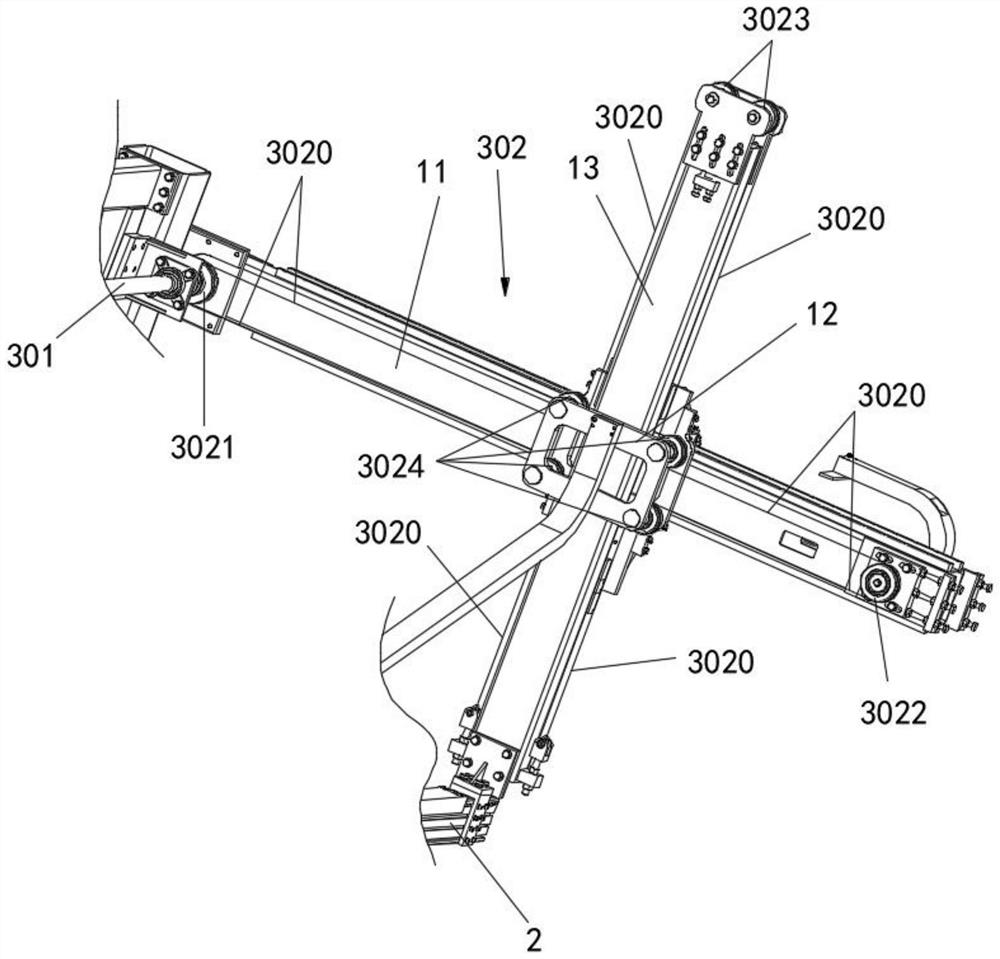

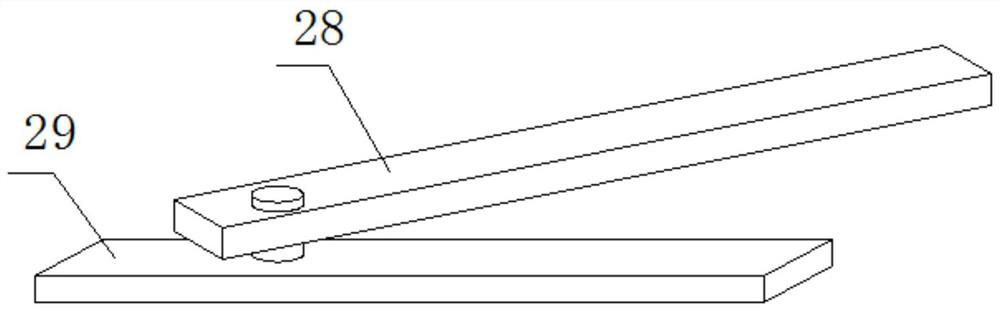

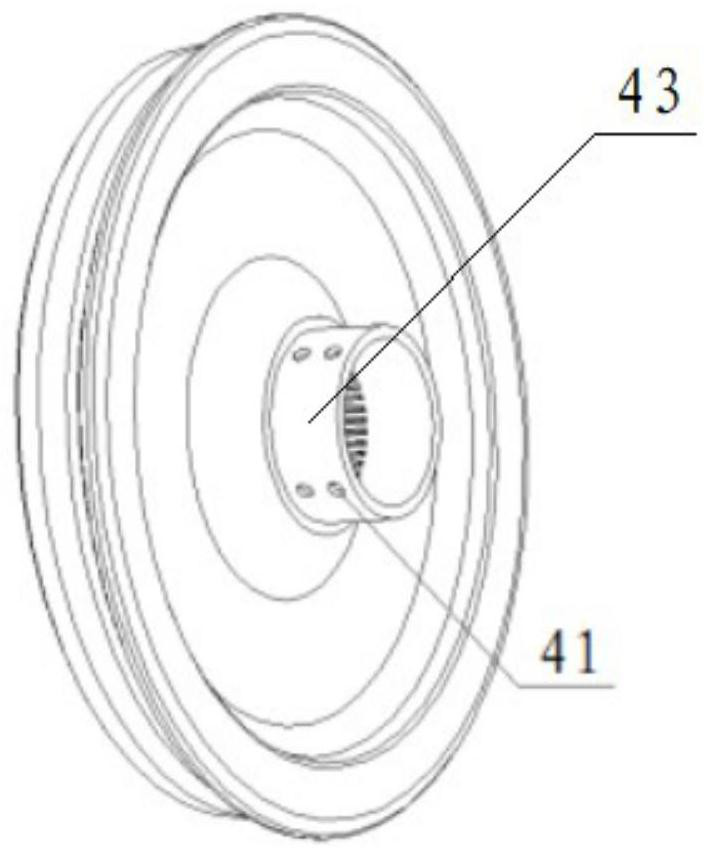

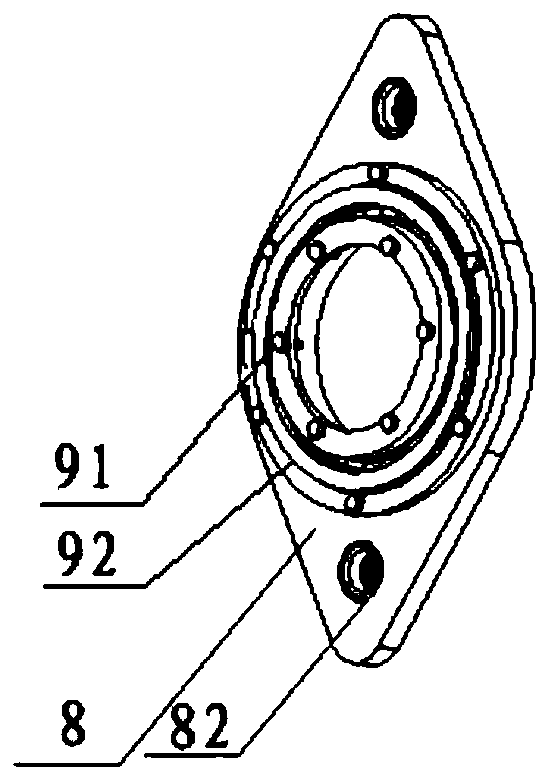

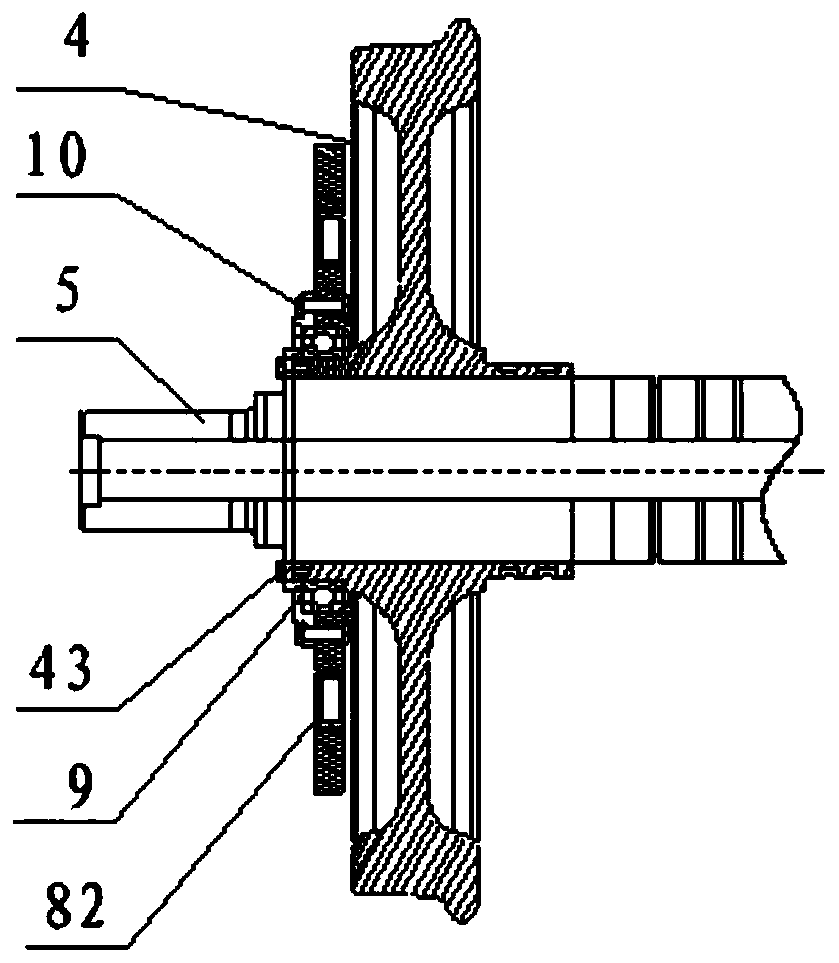

A movable disc assembly for a variable gauge wheel set

The invention relates to the field of rail vehicle variable gauges, and discloses a movable disc assembly for a variable gauge wheel set; the movable disc assembly comprises a movable disc and a bearing, and the movable disc is provided with a central through hole and a connecting hole located outside the central through hole; an outer ring of the bearing is fastened in the central through hole, and an inner ring of the bearing is used for being fixedly arranged on an outer hub of a wheel in a sleeving mode. The movable disc assembly is simple in structure, and is capable of being fastened towheels and small in an occupied wheel space; a transverse driving mechanism pushes or pulls the movable disc to drive the wheels to move, and gauge changing of the wheels is achieved; by using the movable disc assembly, the transmission torque is large, the reliability is high, the gauge changing reliability is improved, and the gauge changing efficiency is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

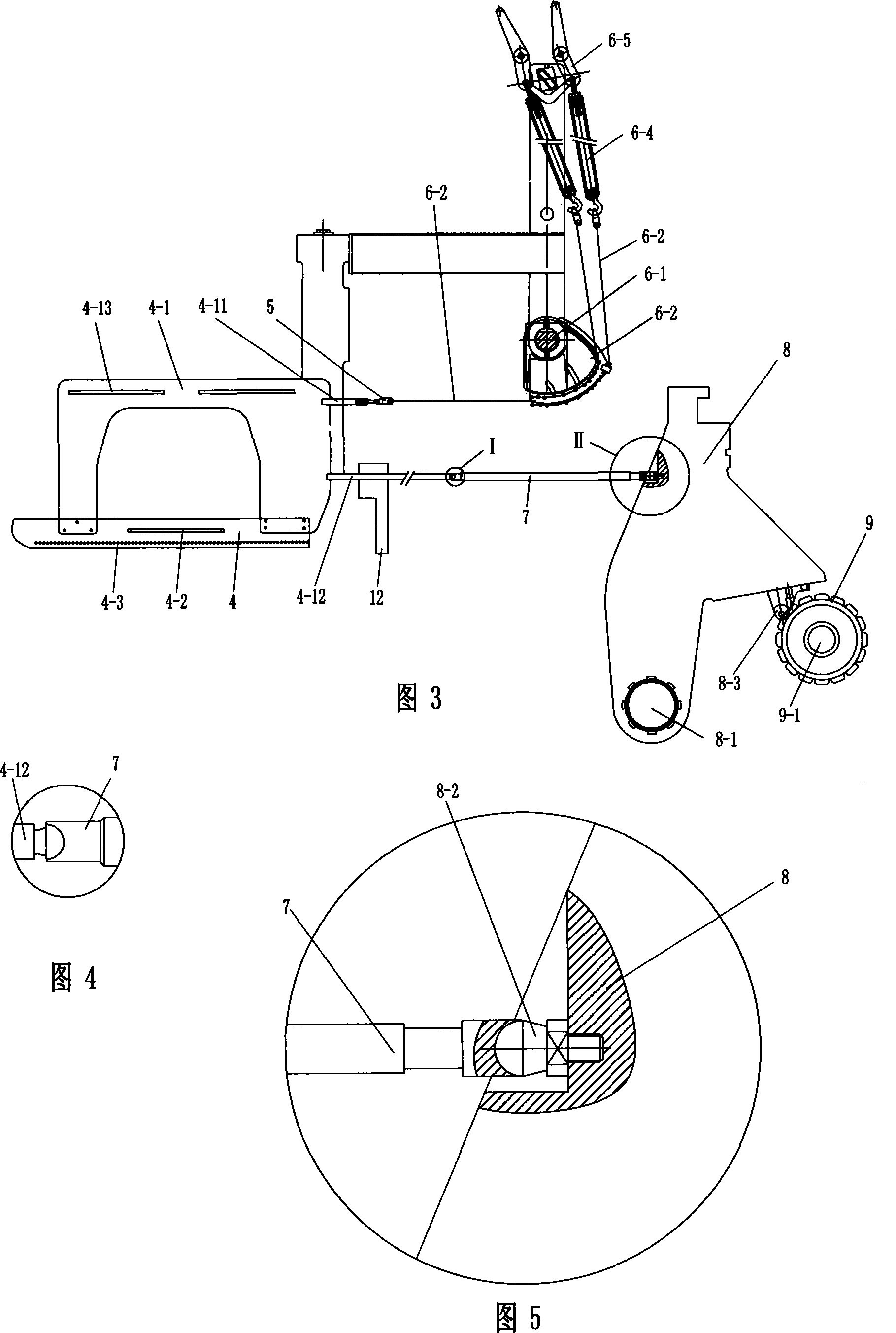

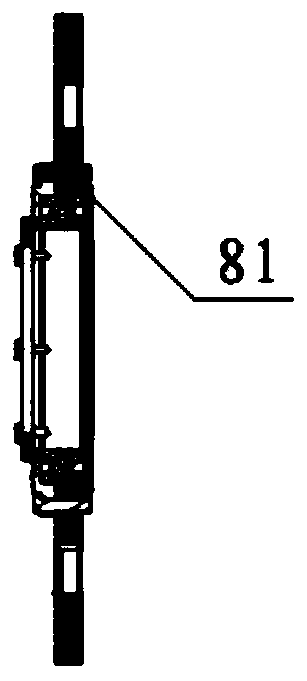

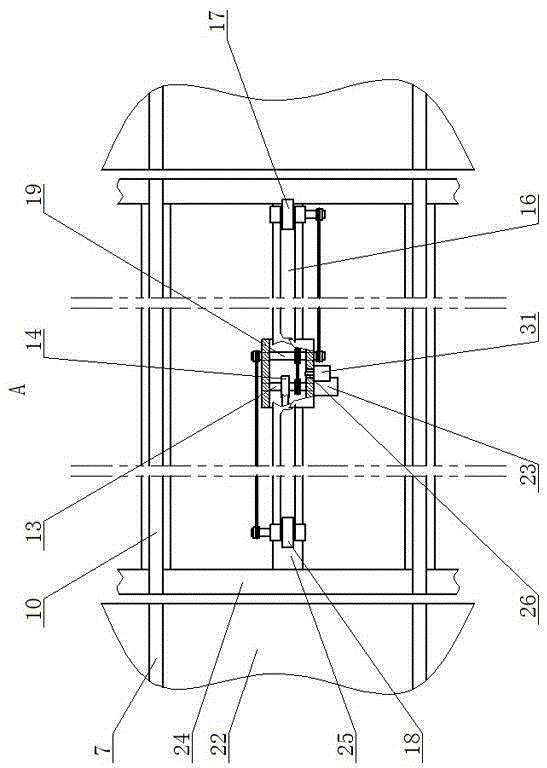

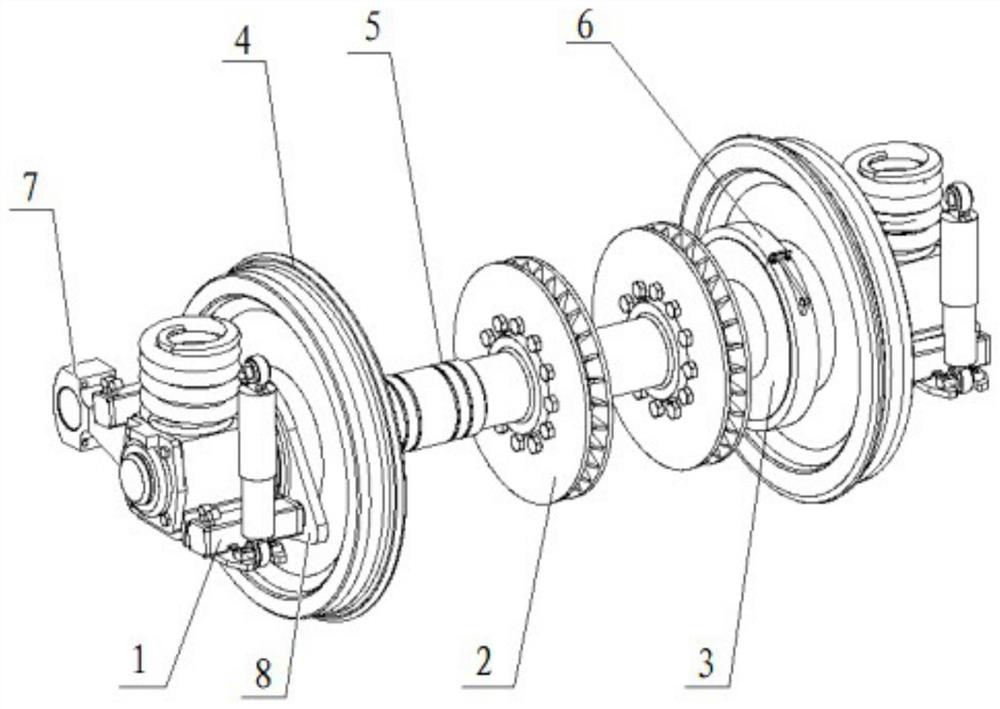

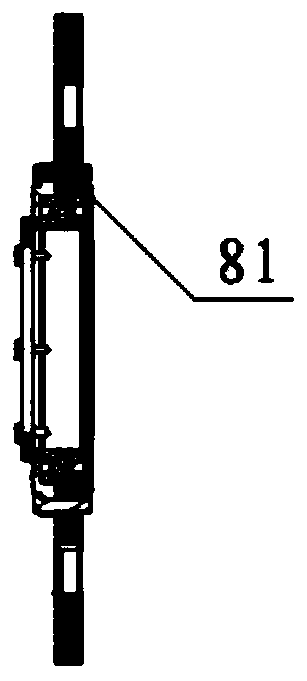

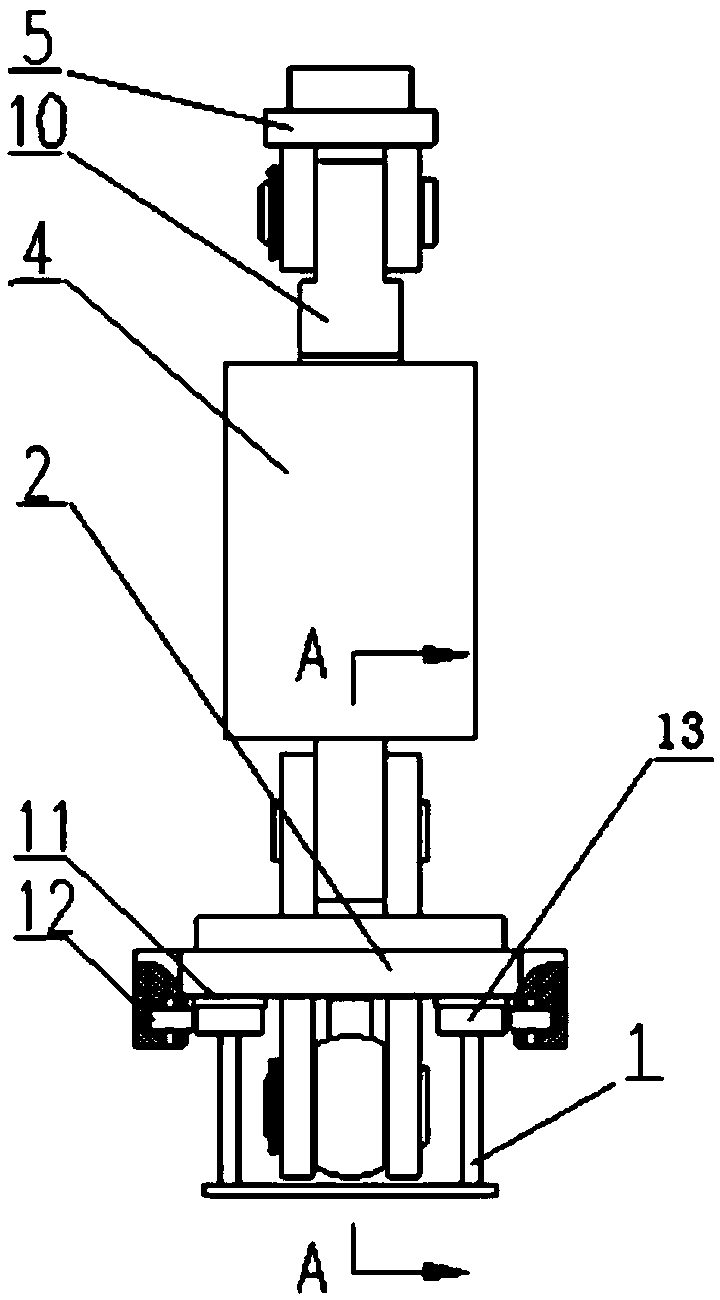

Transverse driving mechanism for gauge-changeable wheel set and gauge-changeable wheel set

InactiveCN110228497AImprove reliabilityRealize lateral movementAxle unitsAxle-boxesEngineeringMechanical engineering

Owner:CRRC QINGDAO SIFANG CO LTD +1

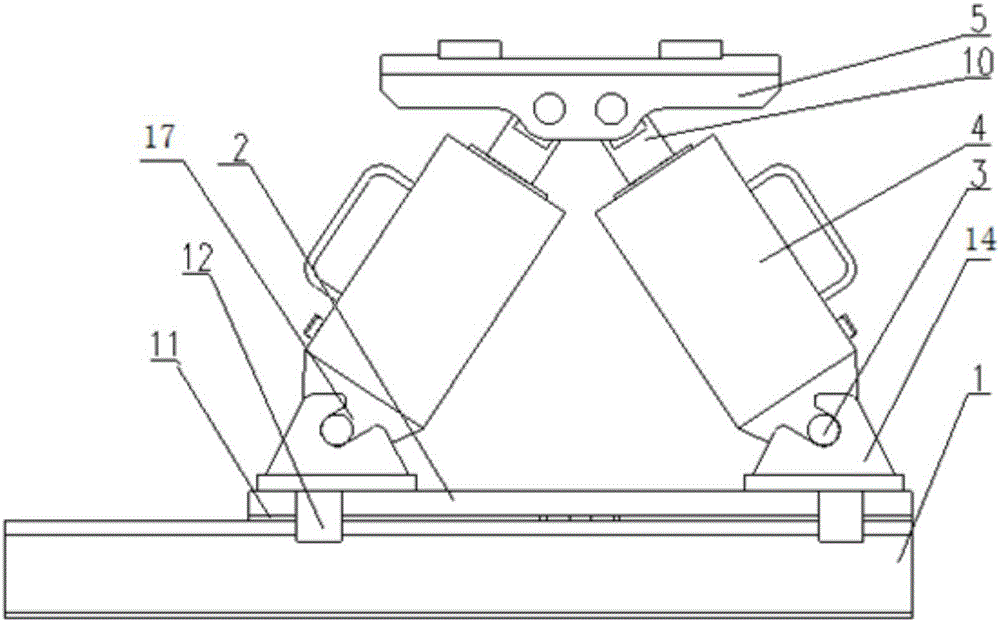

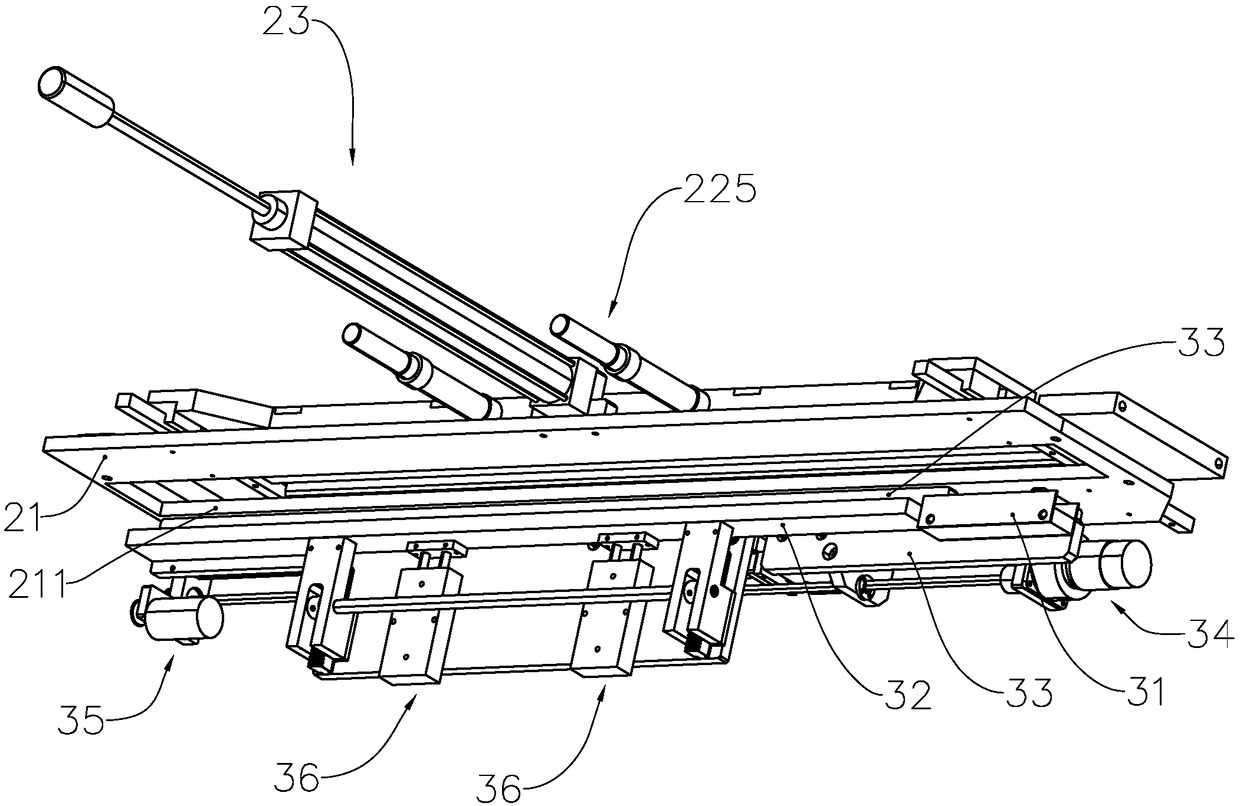

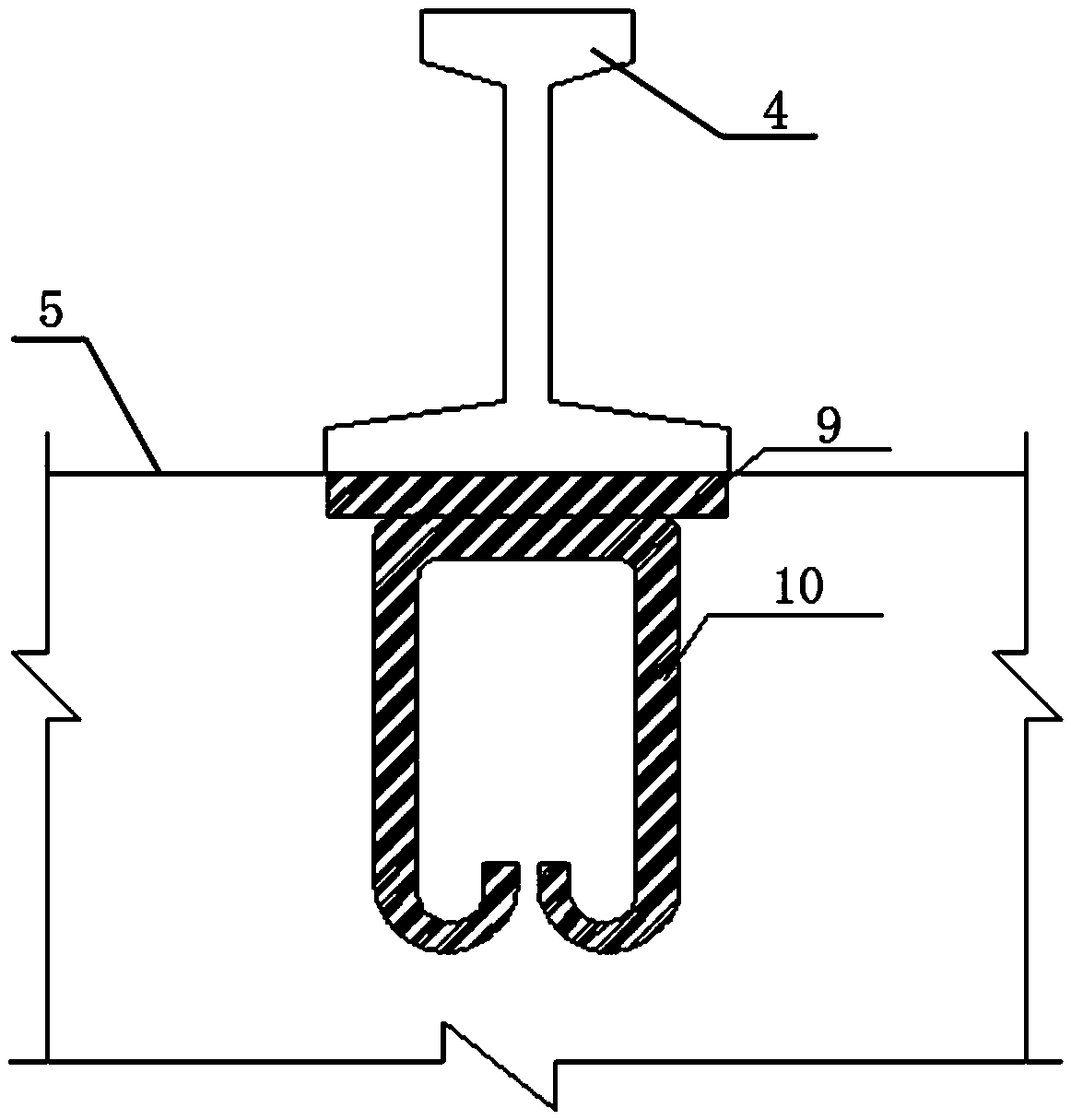

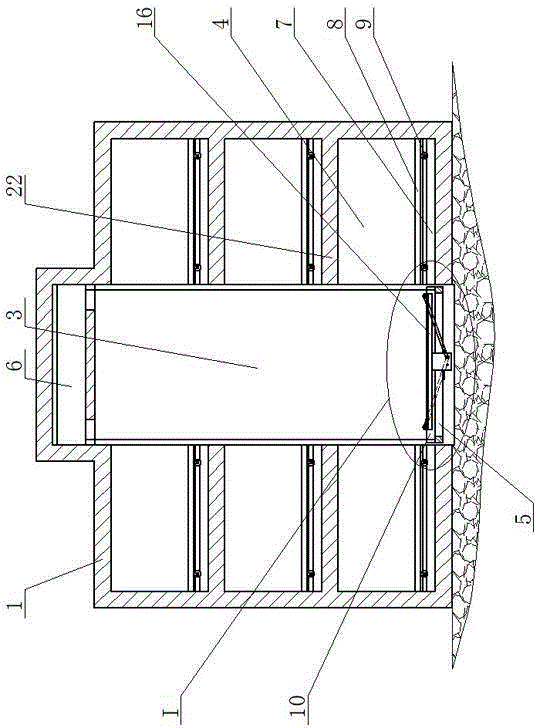

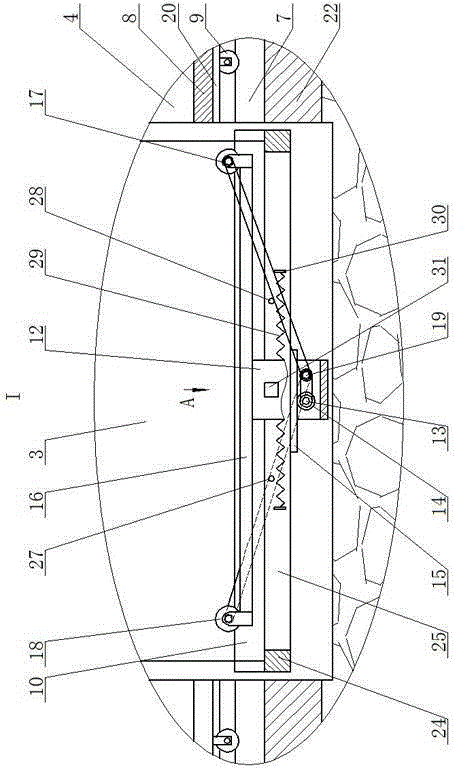

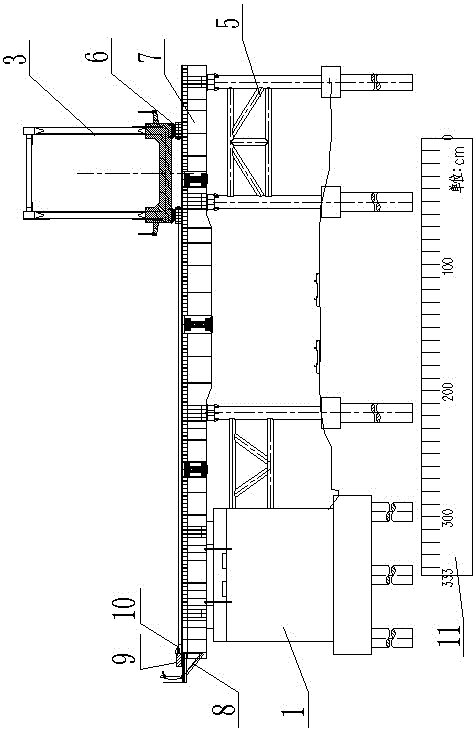

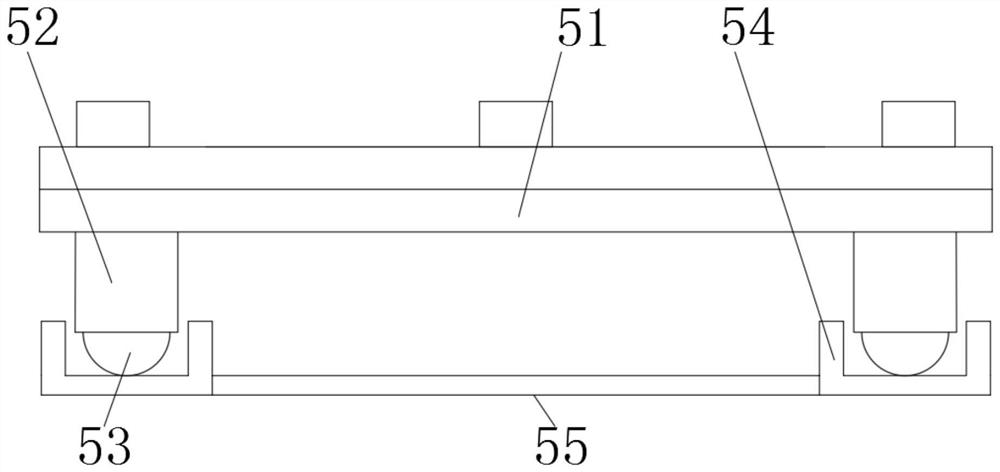

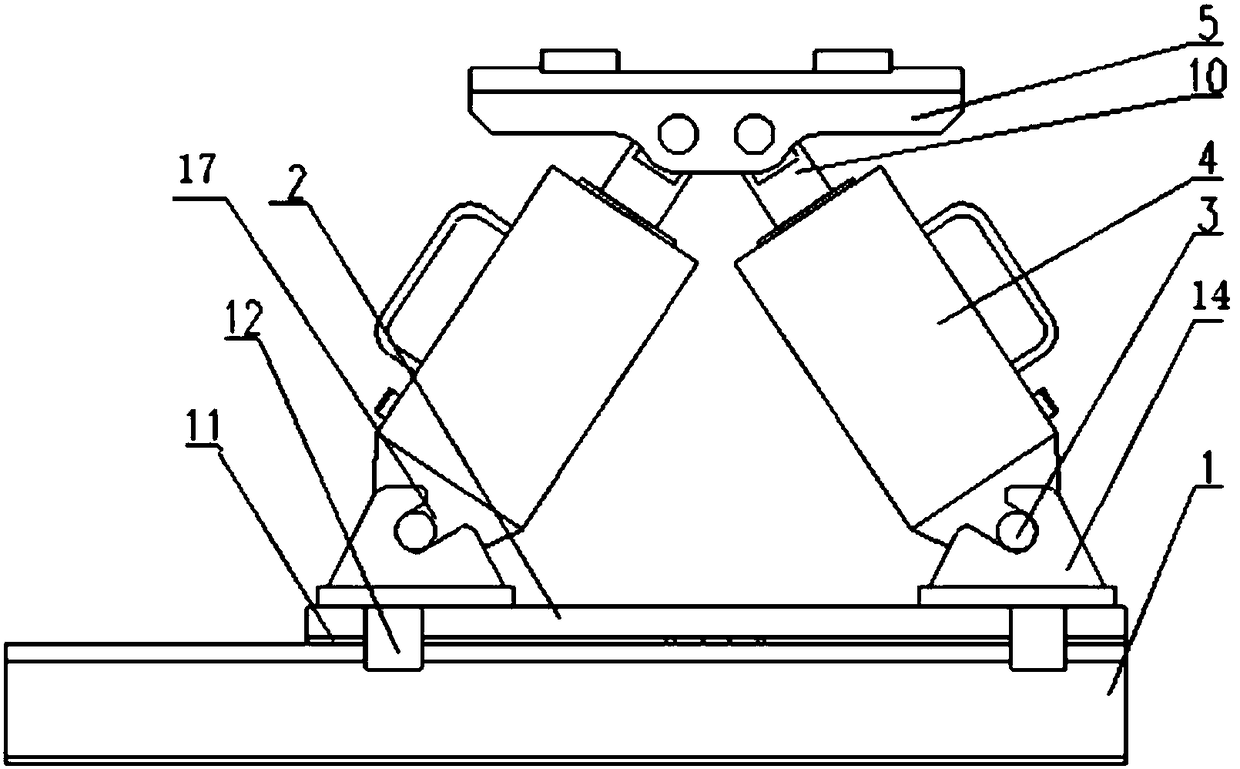

Traverse moving type hydraulic rerailer

ActiveCN106428105AReduce local pressureOvercome the disadvantages of local stress concentrationDevices secured to trackEngineeringStructural engineering

The invention discloses a transverse moving type hydraulic rerailer. A rerailing beam is in a groove-shaped structure with an upward opening, and two sliding rails are fixed to the top ends of two side plates of the rerailing beam in the full length; a moving table capable of sliding left and right is arranged on the sliding rails; a transverse moving cylinder is mounted in the groove-shaped structure, the right end of the transverse moving cylinder is hinged to the right end of the rerailing beam through a first pin shaft, and the left end of the transverse moving cylinder is hinged to the left end of the moving table through a second pin shaft; the bottom ends of two jacking cylinders arranged in a herringbone form are respectively hinged to the moving table through supporting pin shafts; and the piston ends of the two jacking cylinders are symmetrically hinged to positions under a jacking head, so that a triangular stable structure is formed by the moving table, the two jacking cylinder and the jacking head through mutual connection. According to the traverse moving type hydraulic rerailer disclosed by the invention, a jacking part adopts the triangular stable structure, and a traverse moving part adopts a sliding structure, so that not only is the stability of the rerailer during rerailing improved, but also the cost is reduced.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

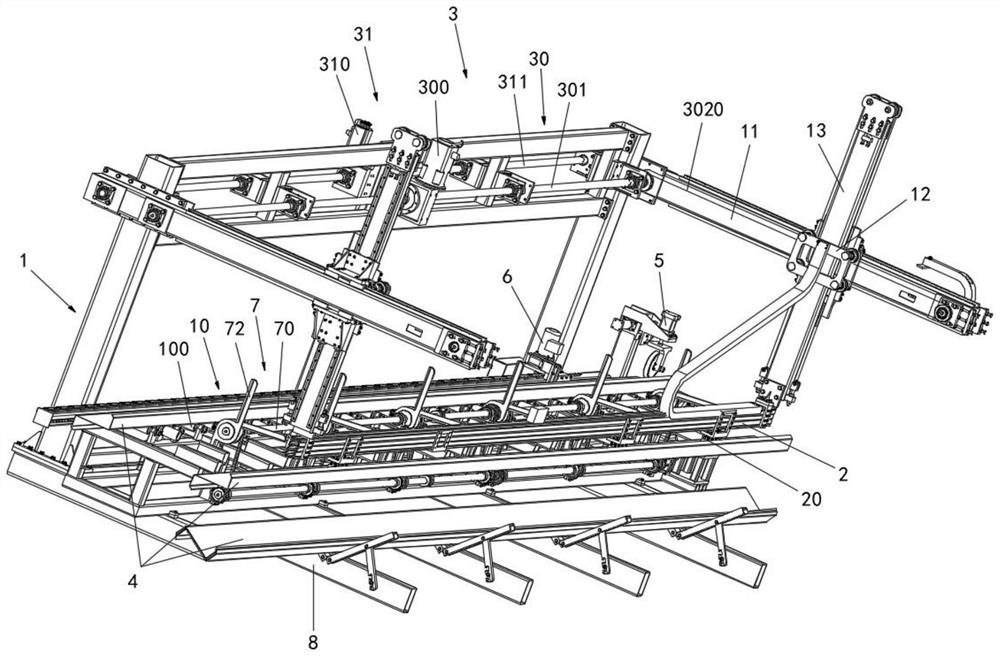

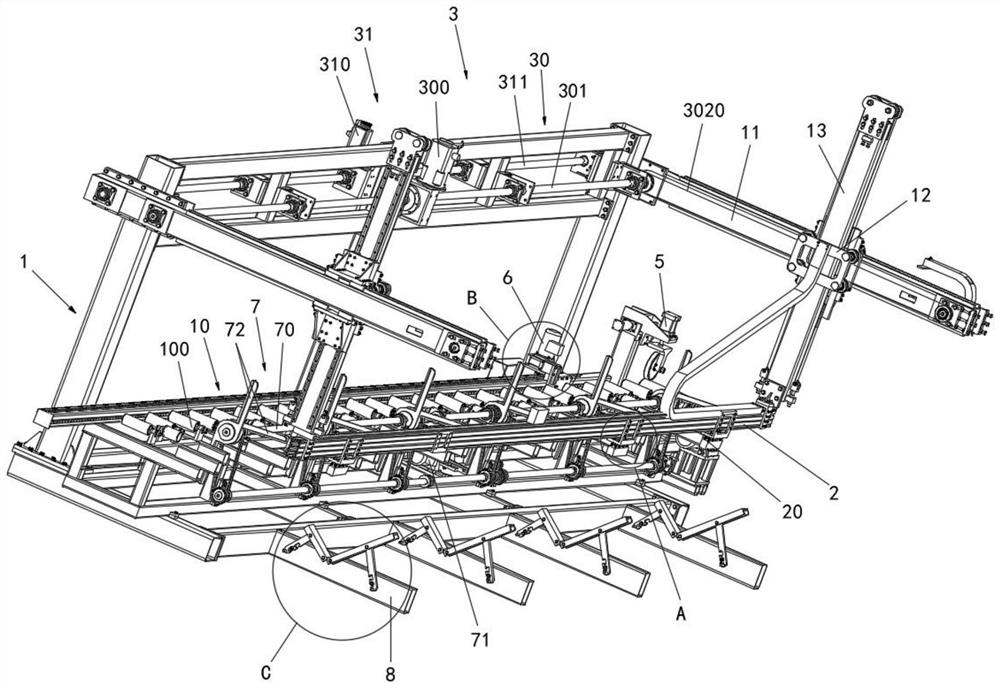

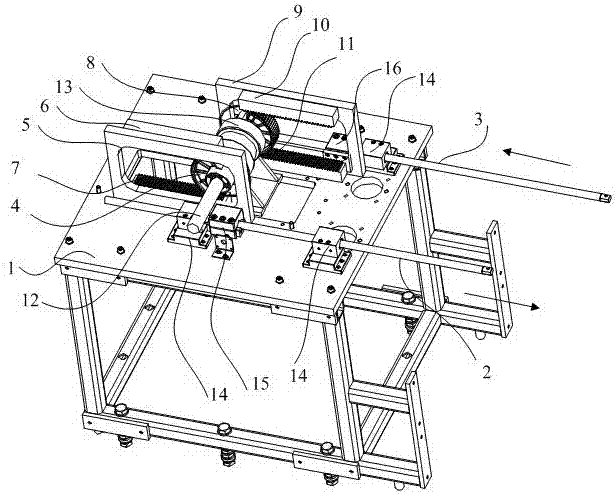

Long and thin profile electromagnetic hoisting and automatic stacking equipment

PendingCN114014216ANeatly stackedIncrease productivityLifting devicesStructural engineeringMechanical engineering

Owner:XIAMEN ZHENGLIMING METALLURGICAL MACHINERY

Motorcycle orientation column bearing assembling method

InactiveCN103341754ASimple structureFirmly connectedMetal working apparatusStructural engineeringHydraulic pressure

The invention discloses a motorcycle orientation column bearing assembling method which is characterized in that a single-column hydraulic press is used, an installation boss is arranged on an installation platform of the single-column hydraulic press and is right towards a hydraulic column above, a through hole is vertically formed in the installation boss, after an orientation bearing to be installed is sleeved on an orientation column, the lower end of the orientation column is inserted in the through hole, the lower end face of the orientation bearing is arranged on the upper surface of the installation boss, the hydraulic column of the hydraulic press is started to press down, so that a hydraulic head on the lower portion of the hydraulic column presses a connector at the upper end of the orientation column downwards, and the orientation bearing is forcedly placed in a work station in a pressing mode. According to the motorcycle orientation column bearing assembling method, an auxiliary tool is further arranged for assembling to save time, the single-column hydraulic press is used for assembling, installation accuracy and reliability can be improved, and meanwhile the auxiliary tool is further used, so that the rising and falling stroke of the hydraulic column can be effectively shortened. The motorcycle orientation column bearing assembling method has the advantages that implementation is easy, assembling time can be saved, and assembling efficiency is improved.

Owner:力帆科技(集团)股份有限公司

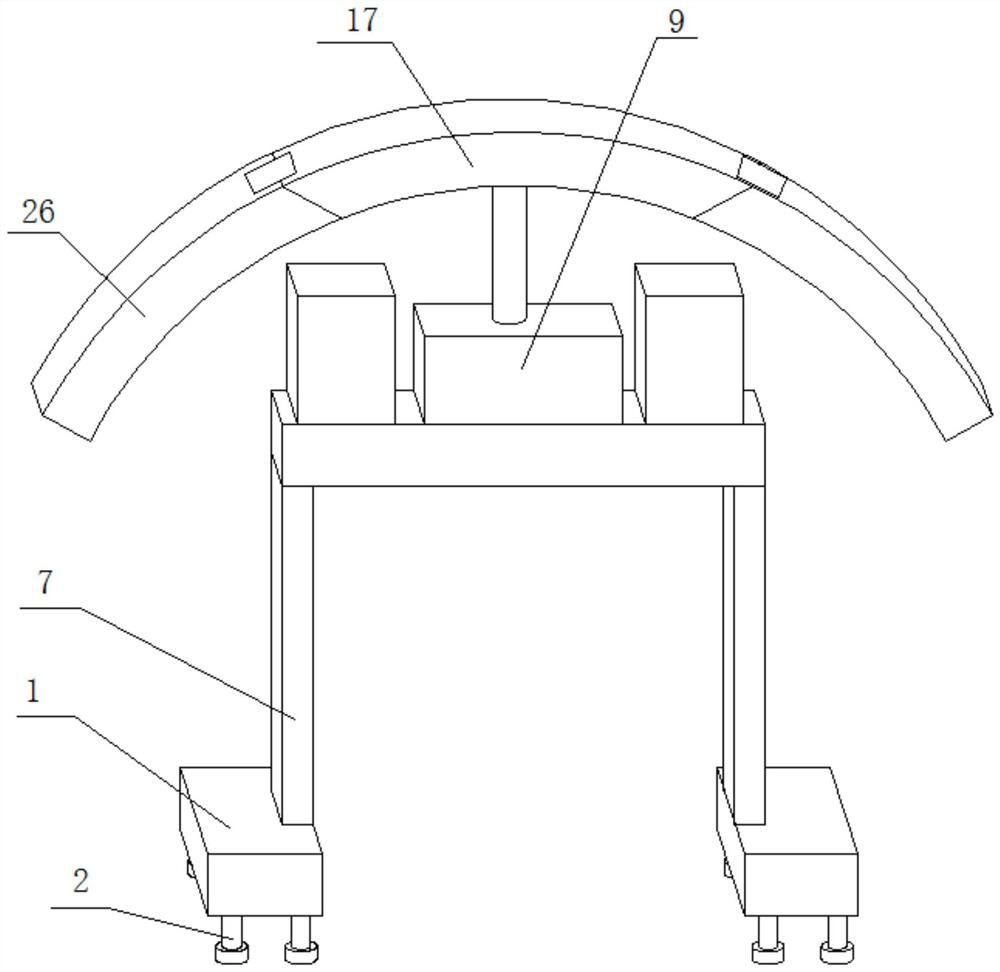

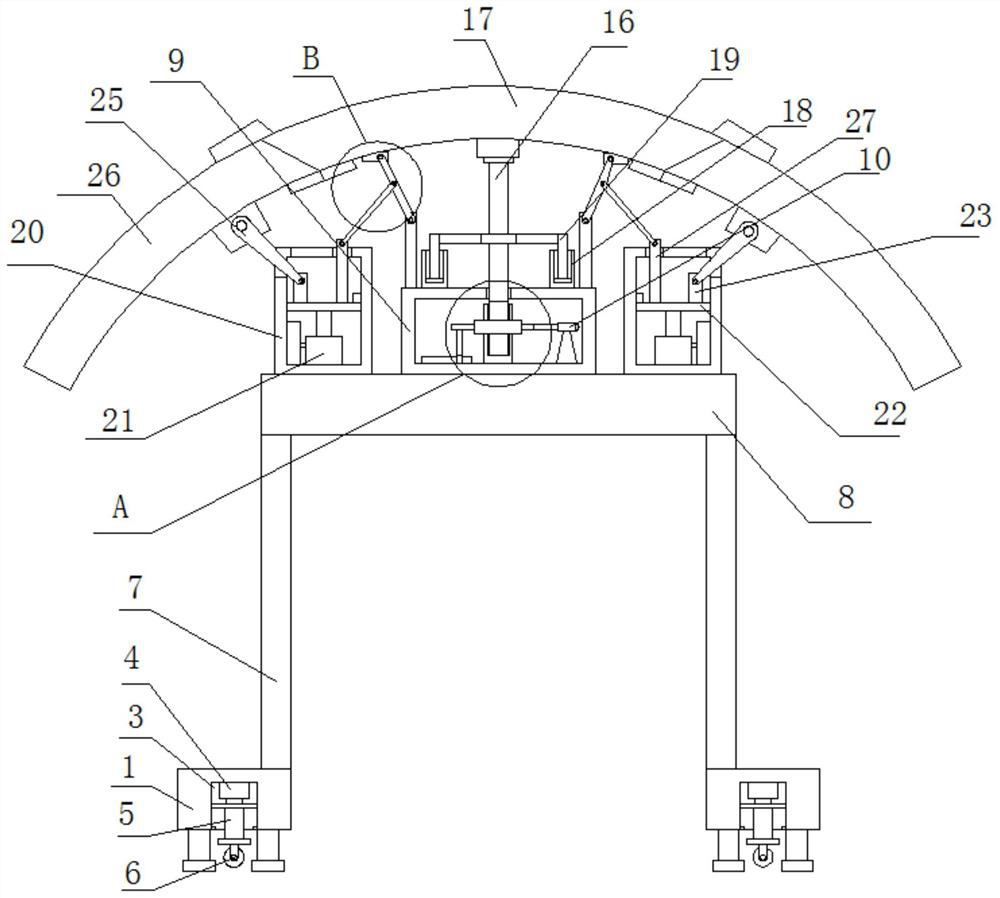

Temporary combined supporting device for tunnel fracture zone

The invention belongs to the field of combined supporting equipment, and particularly relates to a temporary combined supporting device for a tunnel fracture zone. A same cross beam is fixedly mountedat the tops of two vertical plates at the top of a base; a supporting seat is fixedly mounted in the center of the top of the cross beam; the top of a vertical shaft of the inner wall of the top of the supporting seat penetrates through the inner wall of the top of the supporting seat and extends to the position above the supporting seat; a main arc-shaped plate is rotationally mounted at the topof the vertical shaft; a supporting component is arranged at the bottom of the vertical shaft; and side face arc-shaped plates are hinged to the two sides of the main arc-shaped plate; the two side face arc-shaped plates are concentric with the main arc-shaped plate; top storage chambers of the cross beam are located on the two sides of the supporting seat correspondingly; a same push plate is mounted on the inner walls of the two sides of each storage chamber in a sliding mode; storage components are rotationally arranged at the tops of the two push plates correspondingly; and the tops of the two storage components are rotationally connected with the bottoms of the two side face arc-shaped plates correspondingly. The problems that a primary supporting device occupies larger space and iscomplex to carry in practical application are solved.

Owner:瞿启芳

A variable-gauge wheel set and a variable-gauge bogie

The invention relates to the field of rail vehicle gauge change, and discloses a gauge change wheel set and a gauge change bogie, including wheels, axles, locking mechanisms and lateral drive mechanisms, the wheels and axles are connected by splines, and the axles are located on the wheels The outer two ends are respectively supported in the axle box; the locking mechanism is respectively arranged on the inner side of each wheel, the locking mechanism includes a traction electromagnet, the traction electromagnet includes a traction coil and a moving iron core driven by the traction coil, and the wheel A plurality of locking holes are arranged at intervals along the axial direction on the inner hub of the inner wheel, and the moving iron core can extend into or leave the locking holes to realize wheel locking or unlocking; the lateral driving mechanism is respectively arranged on the outer side of each wheel and fixed on the On the axle box body, the transverse driving mechanism includes an electric cylinder, and the protruding end of the electric cylinder is used to push or pull the unlocked wheel to realize wheel gauge change. The invention can reduce the abrasion between wheel axles, improve the reliability of track gauge change, and improve the track change efficiency.

Owner:CRRC QINGDAO SIFANG CO LTD +1

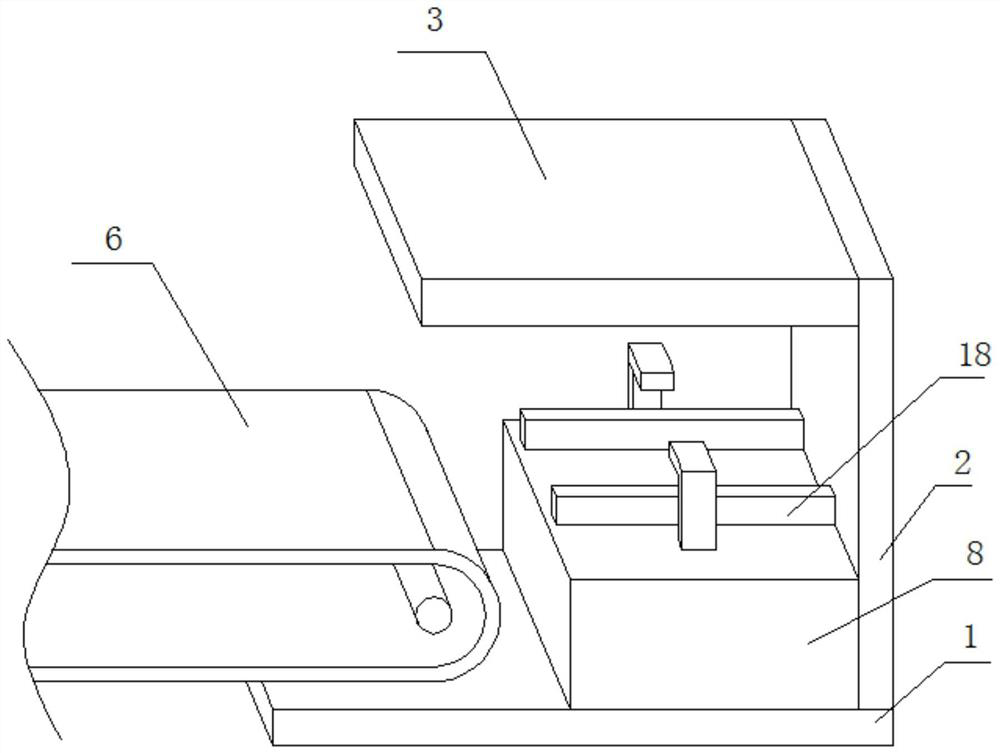

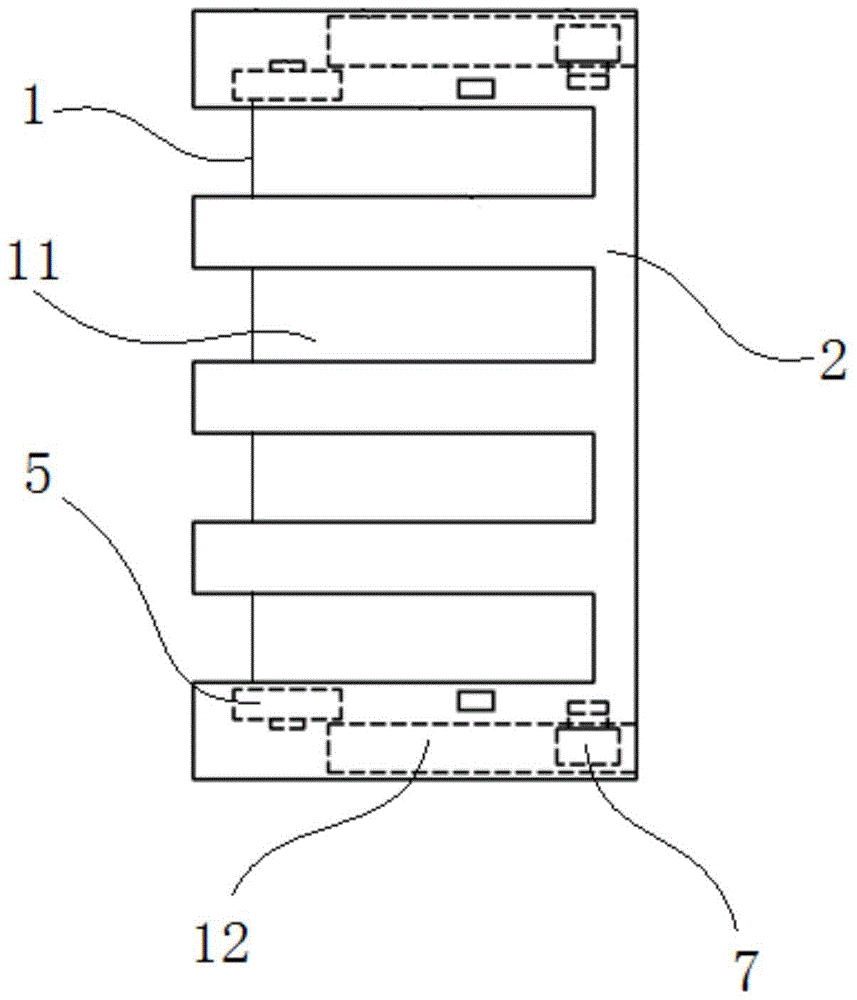

Automatic feeding and pressing device for communication circuit board chip

ActiveCN112478771ALocation pinpointingImprove feeding efficiencyConveyorsControl devices for conveyorsElectric machineryStructural engineering

The invention relates to an automatic feeding and pressing device for a communication circuit board chip. A mounting plate is fixedly mounted on one side of a vertical plate at the top of a base; a driving shaft at the top of the base is in transmission connection with a transmission assembly; the outer side of the driving shaft is in transmission connection with a material conveying belt; rotating shafts are rotationally mounted on the inner walls of the two sides of a clamping table fixedly mounted at the top of the base; L-shaped clamping plates are fixedly mounted at the tops of the two rotating shafts; the same circuit board is clamped at the tops of the two L-shaped clamping plates; a rotating rod is fixedly mounted on one side of a mounting shaft on one side of the vertical plate; an output shaft of a pressing cylinder at the bottom of the rotating rod is located right above a chip area; the mounting shaft is in transmission connection with a rotating assembly; a mounting disc is fixedly mounted at the bottom of an output shaft of a feeding motor at the bottom of the mounting plate; suction cups are fixedly mounted at the bottoms of output shafts of two cylinders at the bottom of the mounting disc; and a control assembly is fixed at the bottom of the mounting plate. The problems that the chip feeding process and the pressing process of a chip feeding and pressing deviceare too tedious and the chip feeding and pressing efficiency is low are solved.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

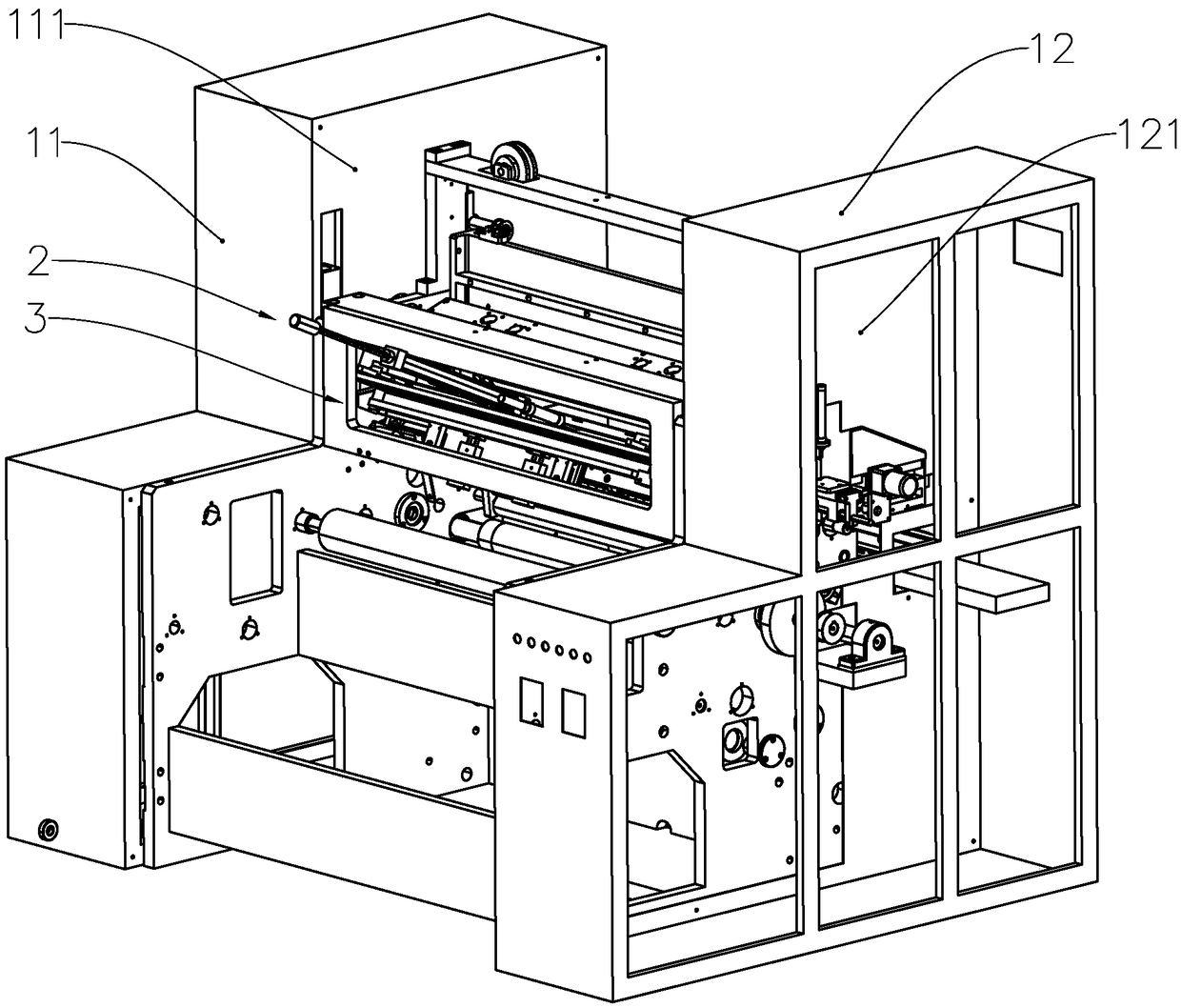

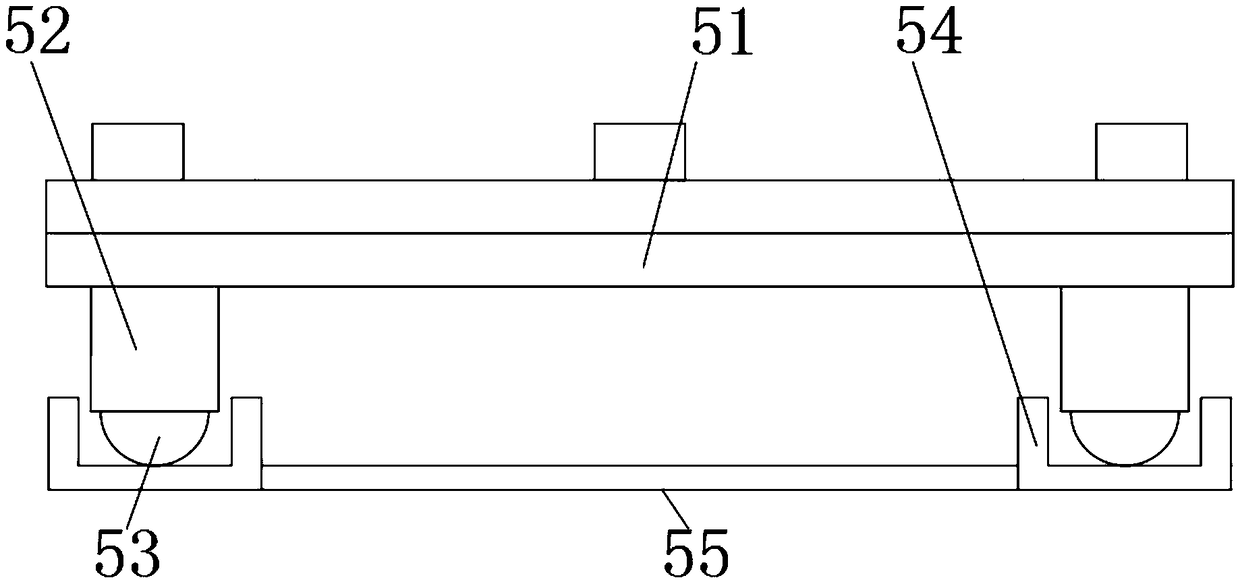

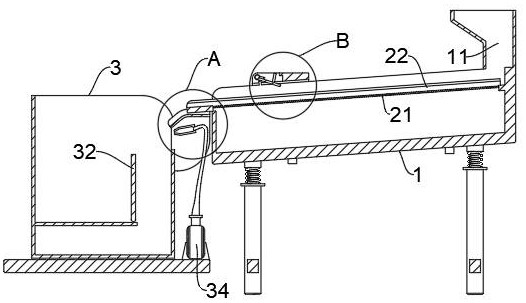

Reelpipe feeding device and paper reeling machine

PendingCN108840144AImprove stabilityAvoid misalignmentWebs handlingEngineeringMechanical engineering

The invention provides a reelpipe feeding device and a paper reeling machine. The reelpipe feeding device comprises a bracket, a bearing rack, a feeding rack and a bearing driving assembly. The bearing rack is movably arranged on the bracket for bearing reelpipes, the bearing rack is arranged in an extended manner along the reelpipe placing direction; the feeding rack is fixedly arranged on the bracket for bearing the reelpipes; the feeding rack is located on the end part of the bearing rack in the reelpipe placing direction; the bearing driving assembly is connected to the bearing rack; the bearing driving assembly drives the bearing rack to move along the reelpipe placing direction; and a separation gap exists between the bearing rack and the feeding rack. The reelpipes in row are pushedto the bearing rack from the feeding rack and after the reelpipes are pushed to a preset length, the bearing rack is driven by the bearing driving assembly to move along the reelpipe placing direction and the separation gap exists between the bearing rack and the feeding rack, that is, the reelpipes are separated by means of transverse movement, and fed pipes and to-be-fed pipe are separated further, so that dislocation or driven dislocation is avoided, and the reelpipe feeding stability is improved effectively.

Owner:ZHUHAI ZHONGYA PACKAGE EQUIP

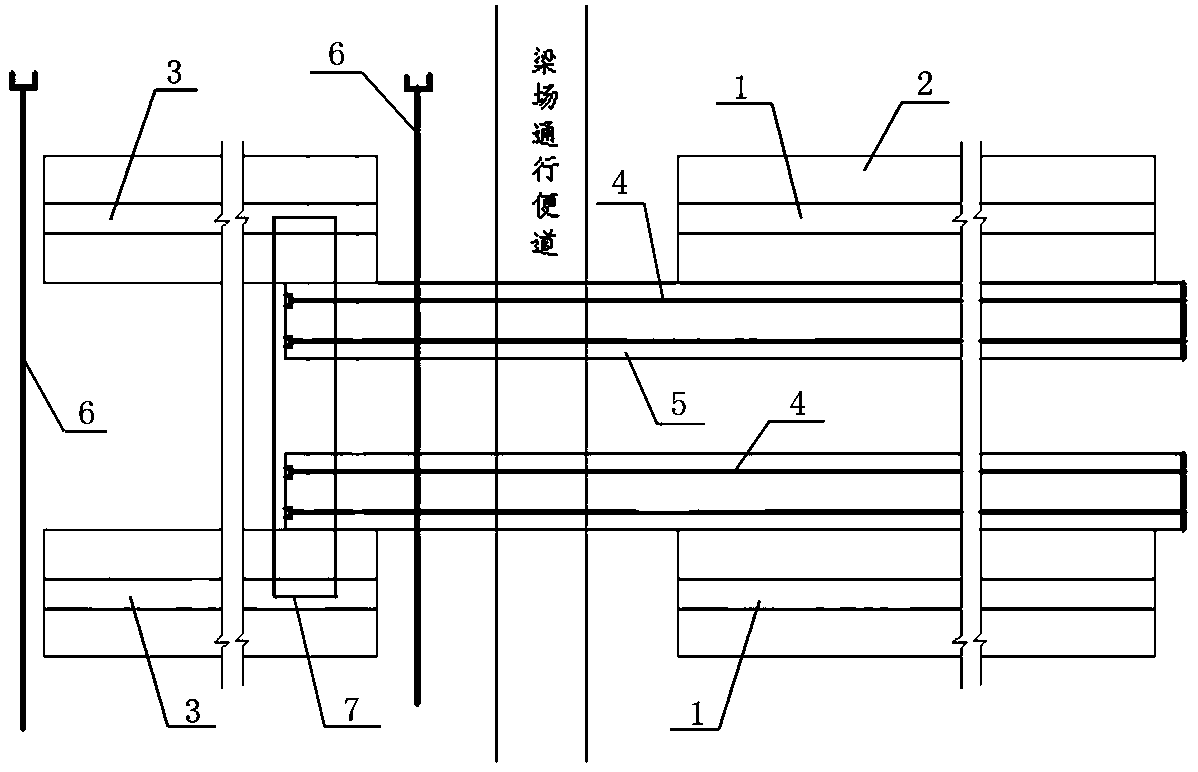

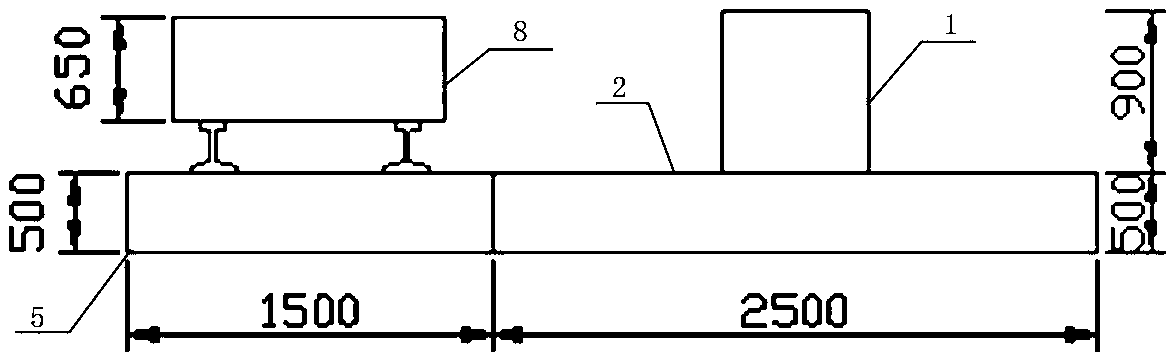

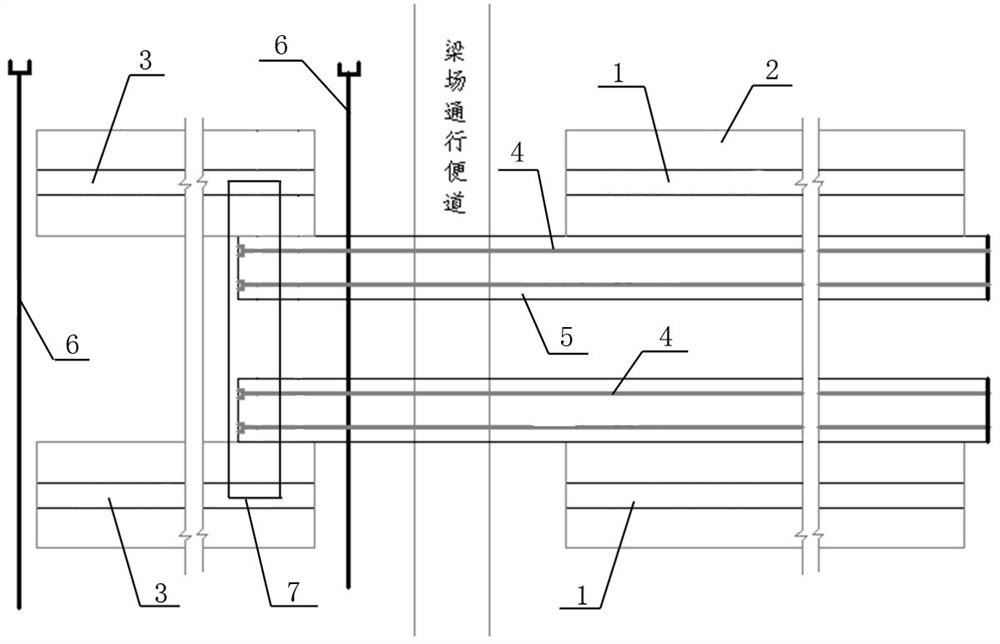

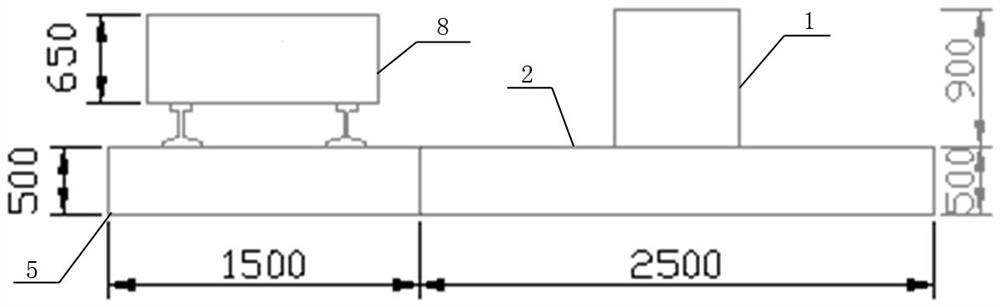

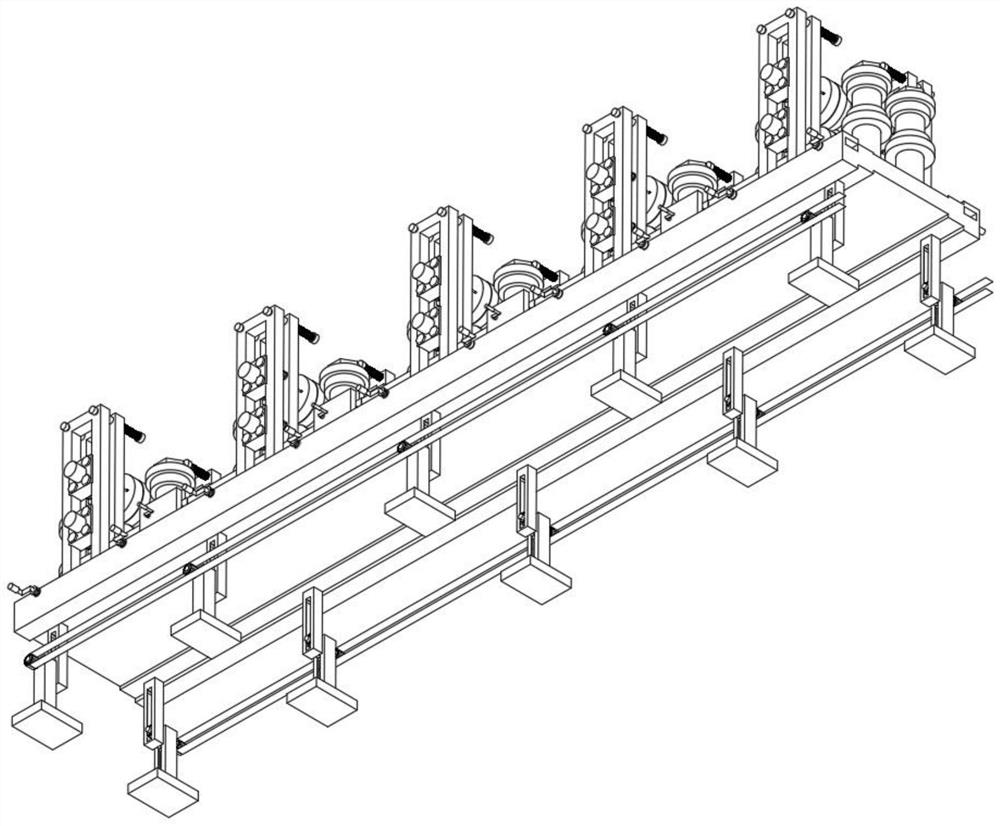

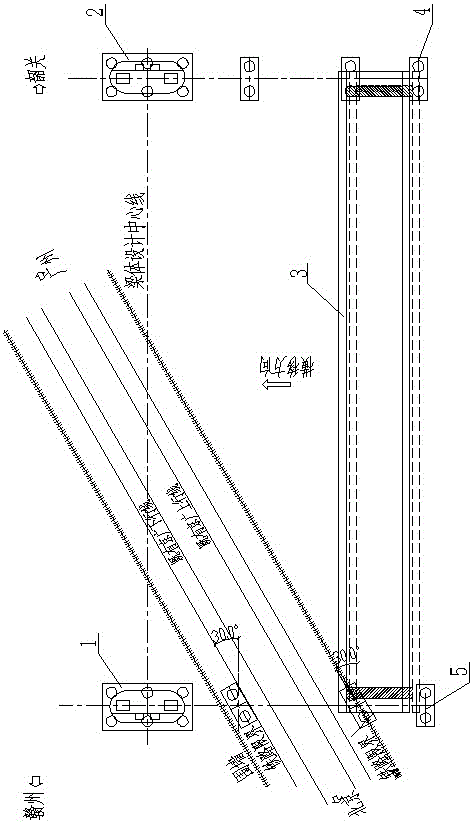

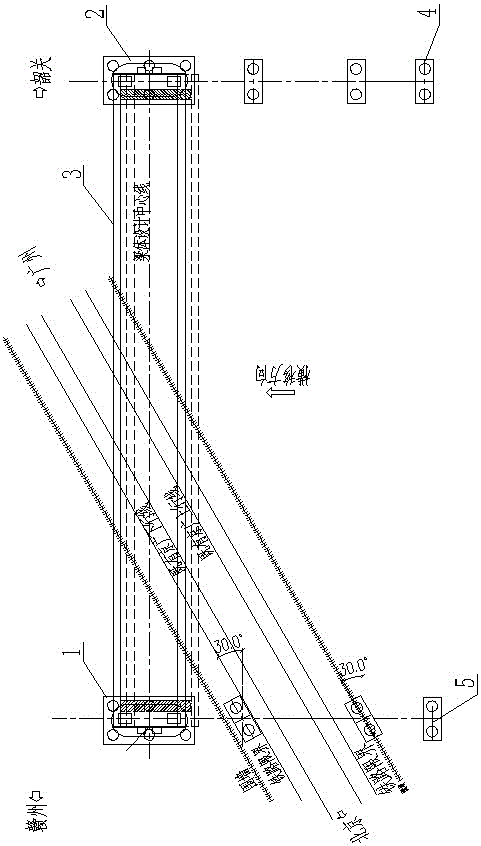

Construction method for horizontal moving beam of double-track trolley

ActiveCN110509424AExpand storage capacityImprove ergonomicsCeramic shaping apparatusT-beamEngineering

The invention relates to a moving method for a T beam of a prefabricated beam factory, in particular to a construction method for a horizontal moving beam of a double-track trolley. The invention adopts two beam-moving trolleys to move beams in a horizontal direction along the track. Jacks are arranged the beam-moving trolleys, the jacks have an automatic lifting function, firstly, the trolleys are moved directly below the T beam in a longitudinal beam storage area, the jacks are started to hold the T beam, so that the T beam breaks away from an original beam storage pedestal. After the reinforcement and stability, the trolleys pull the T beam to move along a horizontal track to a horizontal beam storage area. Then the jacks are depressurized, the T beam is in place, and the trolleys return empty. The construction method realizes the horizontal beam moving, overcomes the problems of the T-beam stability during the cross construction and the beam moving process of the longitudinal andhorizontal tracks, fully utilizes the site width of a precast beam factory, and improves the beam storage capacity of the precast beam factory.

Owner:CHINA RAILWAY SIXTH GROUP +1

Servo drawer stereo garage

Owner:李浩

The Construction Method of Transversely Moving the Beam by the Double Track Trolley

InactiveCN110509424BRealize horizontal beam shiftingIncrease storage capacityCeramic shaping apparatusT-beamClassical mechanics

The invention relates to a method for moving a T-beam in a prefabricated beam factory, in particular to a construction method for laterally moving a beam by a double-track trolley. The invention adopts two beam-moving trolleys to move the beam laterally along the track. A jack is installed inside the beam moving trolley, which has the function of automatic lifting. First, move the trolley to just below the T-beam in the longitudinal beam storage area, and start the jack to lift the T-beam away from the original storage beam pedestal. After reinforcement and stability, the trolley pulls the T beam and runs along the transverse track to the transverse beam storage area. Then the jack releases the pressure, the T beam is in place, and the trolley returns to the empty space. The invention realizes horizontal beam shifting, overcomes the problems of cross construction of vertical and horizontal rails and the stability of T beams in the process of beam shifting, makes full use of the field width of the prefabricated beam factory, and improves the beam storage capacity of the prefabricated beam factory.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

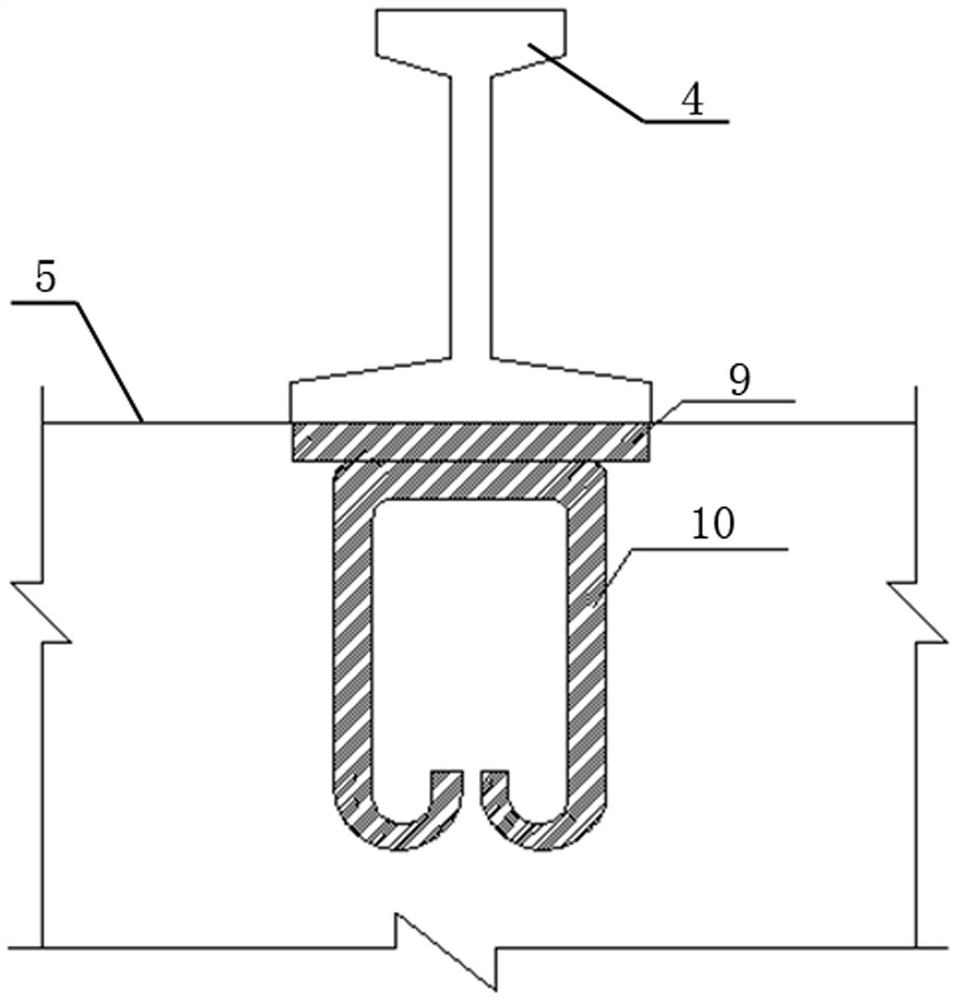

A track-gauge wheel set

ActiveCN110228494BImprove space utilizationCompact structureAxle unitsAxle-boxesClassical mechanicsEngineering

The invention relates to the field of rail vehicle gauge change, and discloses a gauge change wheel set, the wheels of which include a wheel body, the inner side of the wheel body is provided with an inner wheel hub extending inward, and the inner wheel hub is used for installation and locking Mechanism, the outer side of the wheel body is provided with an outer hub extending outward, and the outer hub is used for installing a transverse driving mechanism. The wheel of the invention has compact structure and high space utilization rate, and can adapt to the form of active gauge change, and the gauge change wheel set can improve the reliability of gauge change and the efficiency of track change.

Owner:CRRC QINGDAO SIFANG CO LTD +1

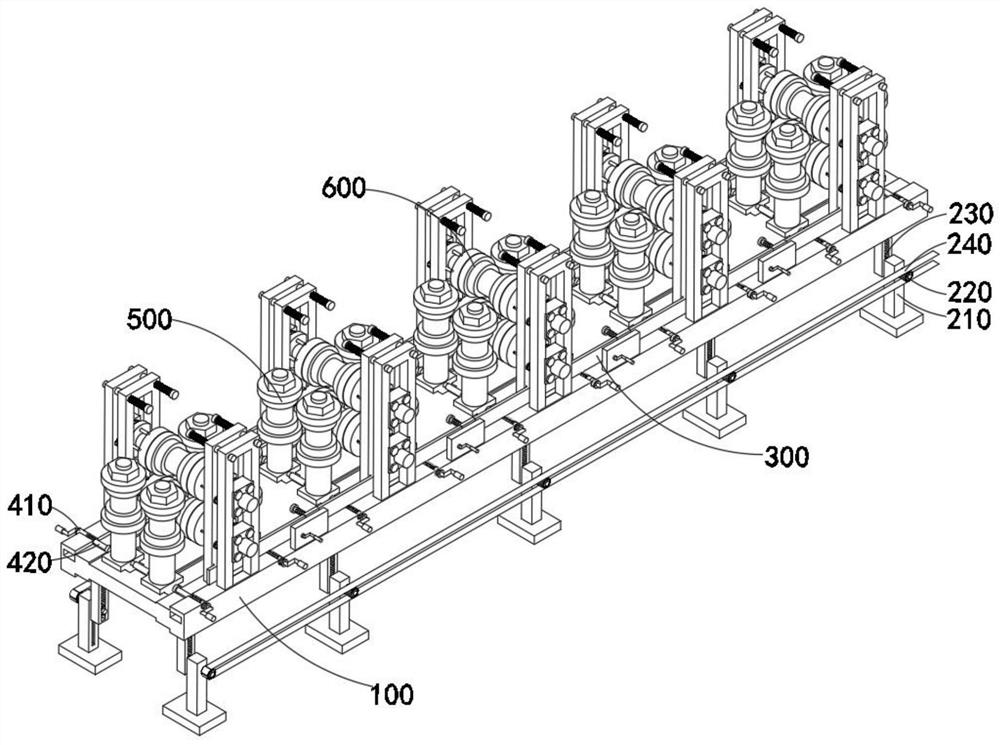

Auxiliary calibration mechanism for special-shaped steel processing

ActiveCN113500111BQuick changeReduce production efficiencyExtrusion diesMetal working apparatusControl engineeringStructural engineering

The invention discloses an auxiliary calibration mechanism for special-shaped steel processing, including a support mechanism, a lifting mechanism, a propulsion mechanism, a fine-tuning assembly, a vertical restraint mechanism, and a special-shaped steel calibration mechanism. The support mechanism includes a working table for providing a stable work flow, The lifting mechanism is installed on the bottom of the worktable, the propulsion mechanism includes a balance part and a driving part, and the balance part includes steel slats, inner pads installed at intervals outside the steel slats and welded on the inner pads Central screw. By setting the worktable, the groove and chute on the top of the worktable are used to fit and install the passive calibration combination. When the mold needs to be replaced, the operator only needs to rotate the deflection chainring counterclockwise, so that the pull rod on the deflection chainring comes The driving screw rotates, and at this time, the screw drives the screw sleeve, thereby prompting the steel slats to drive multiple sets of inner frames to shrink inward, which greatly facilitates the rapid replacement of the mold by the operator.

Owner:江苏华杰不锈钢制品有限公司

A mobile disc assembly for a variable gauge wheel set

ActiveCN110228499BSimple structureSave spaceRail-engaging wheelsAxle unitsClassical mechanicsControl theory

Owner:CRRC QINGDAO SIFANG CO LTD

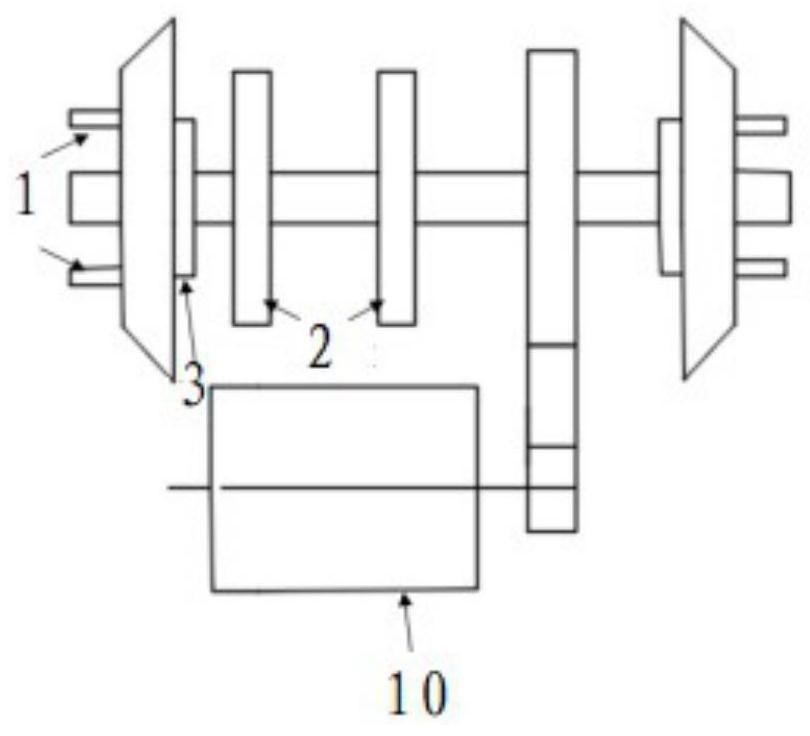

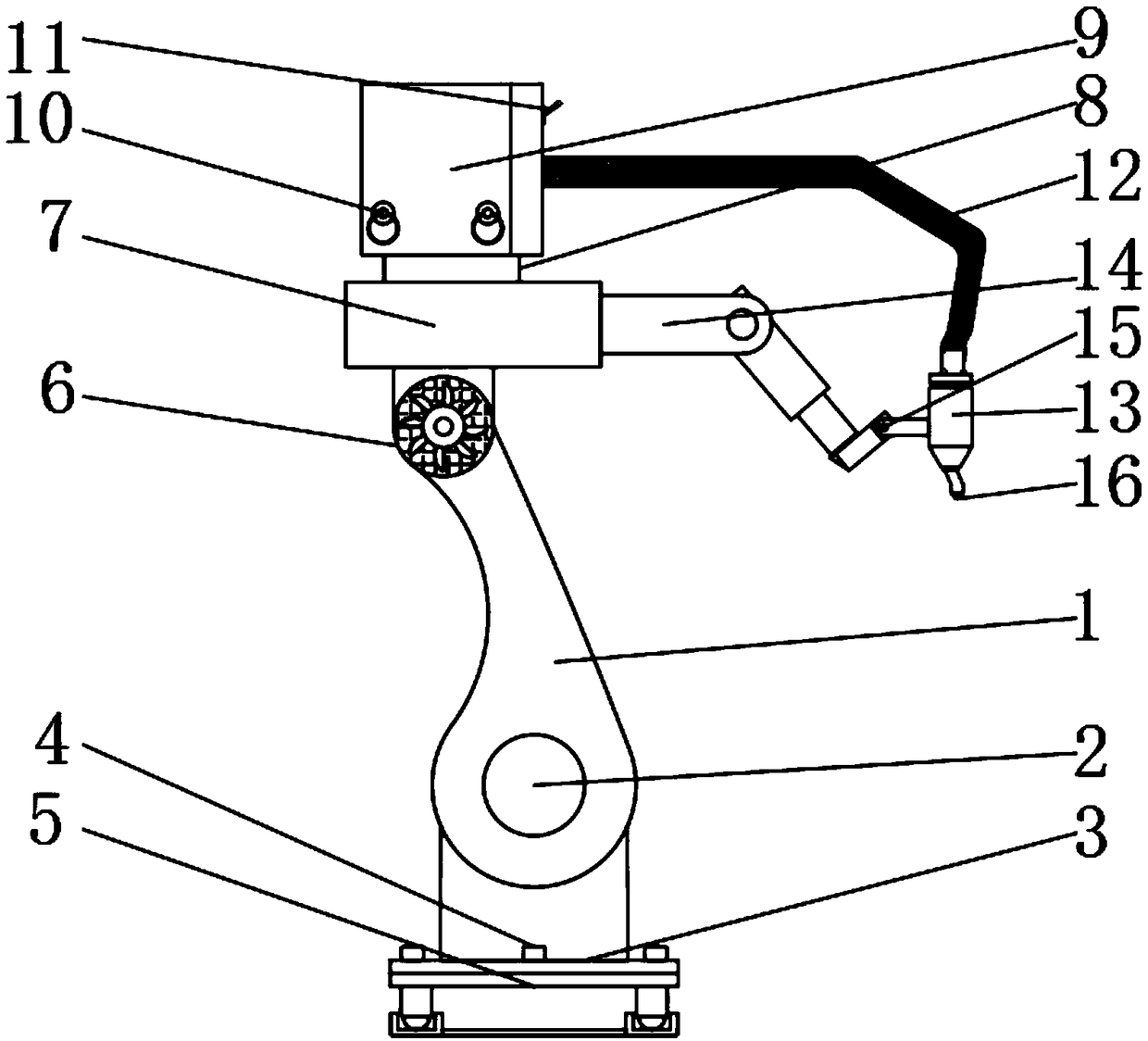

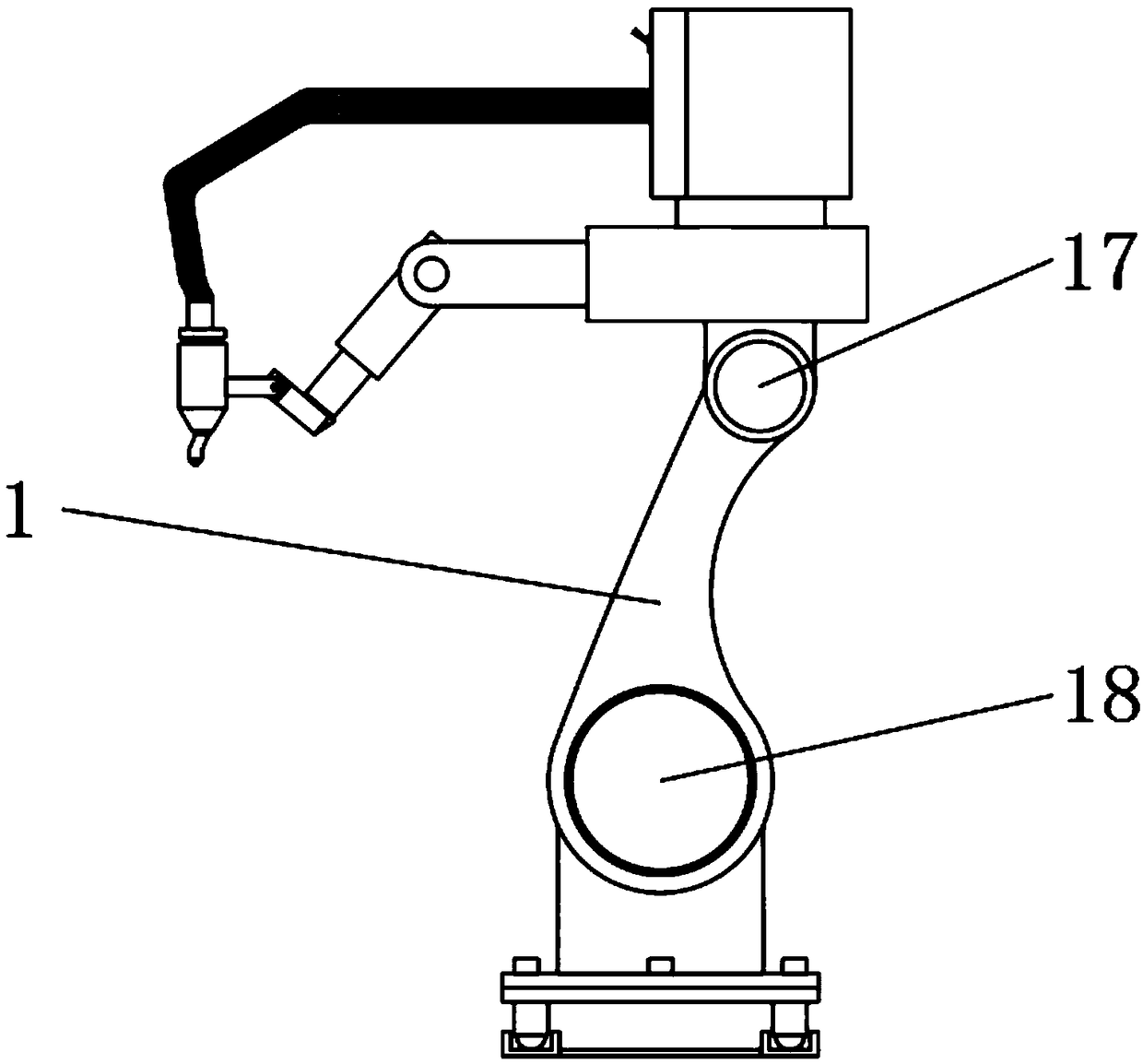

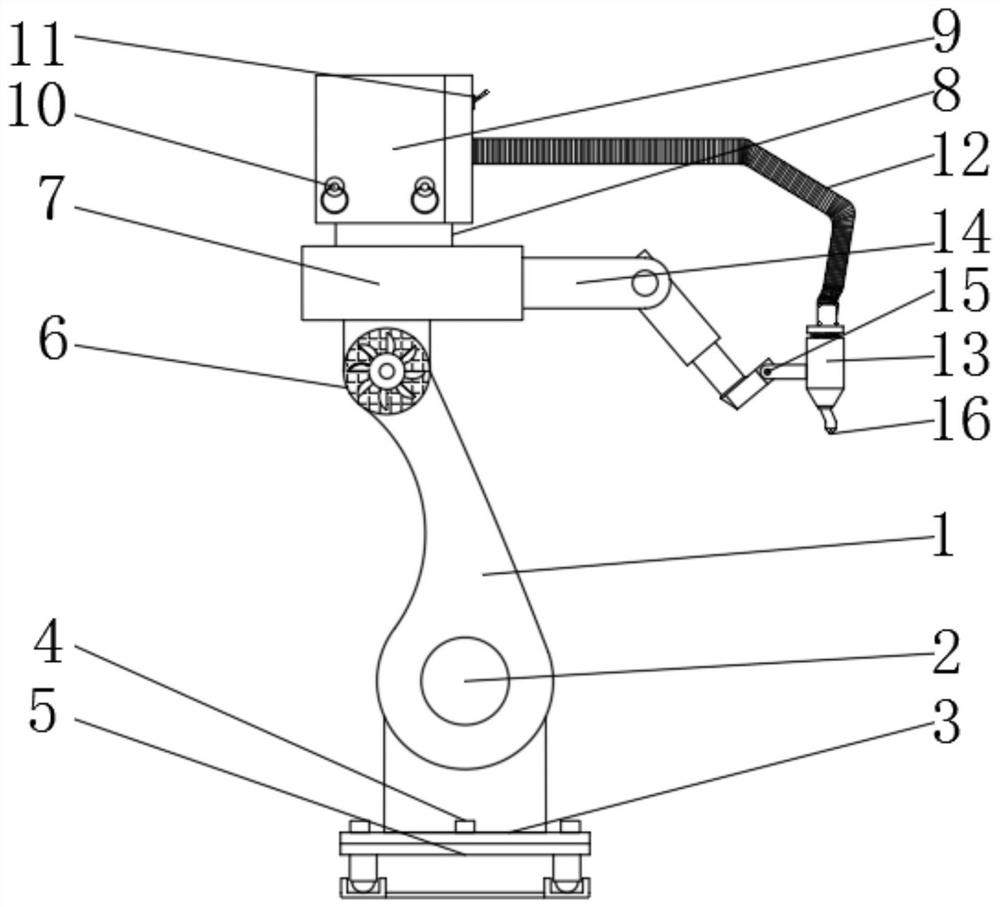

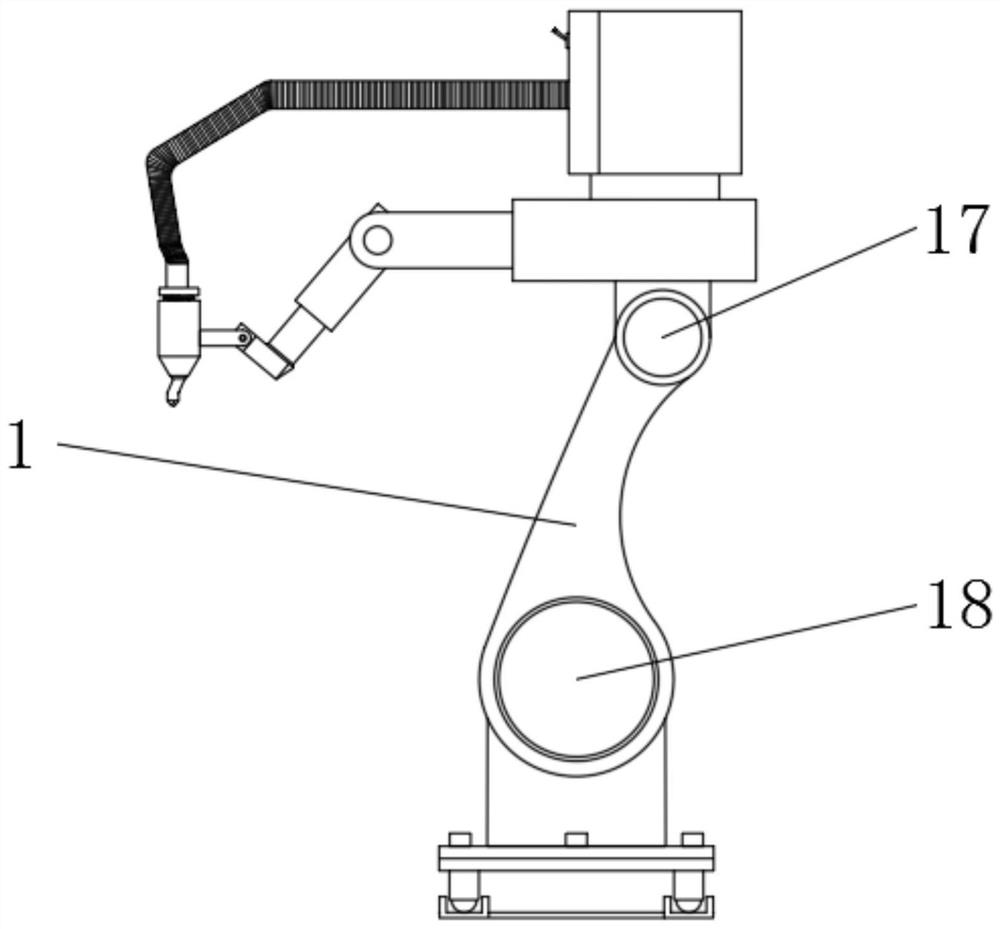

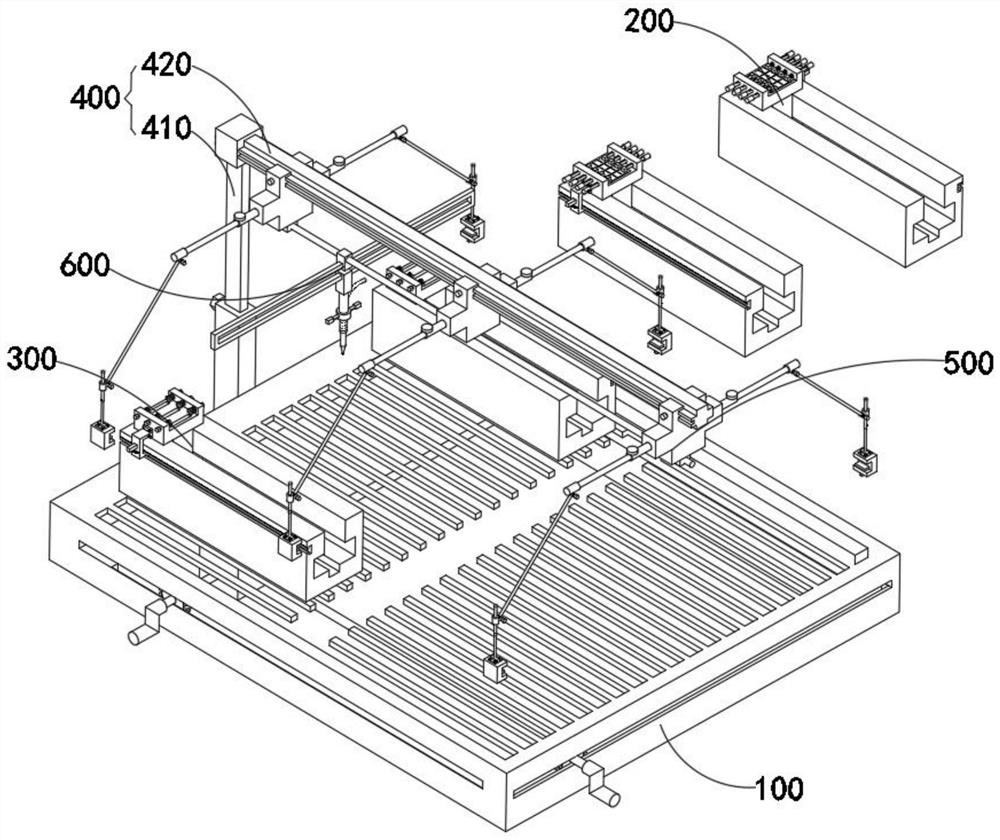

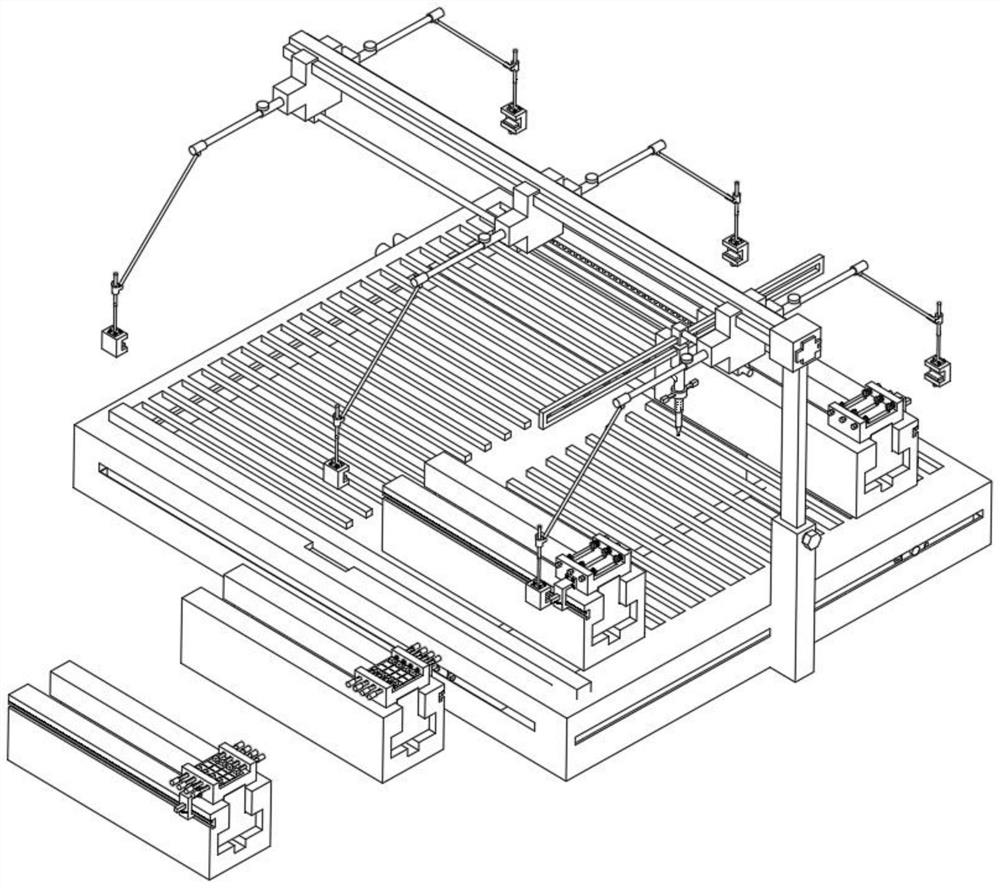

Paint spraying robot

ActiveCN108970869AExpand the scope of paintingSmooth traverseLiquid spraying apparatusPaint robotEngineering

The invention relates to the technical field of functional robots and discloses a paint spraying robot. The paint spraying robot comprises a supporting column. The lower end of the supporting column is provided with a first rotary shaft. A base is arranged under the first rotary shaft. Fixing bolts penetrate through the inner side of the base. A moving component is arranged on the outer surfaces of the lower ends of the fixing bolts. A heat dissipation device is arranged on the upper portion of the outer surface of the front end of the supporting column. The upper end of the heat dissipation device is provided with a telescopic outer rod. The outer surface of the upper end of the telescopic outer rod is provided with a fixed plate. The upper end of the fixed plate is provided with a paintbox. The lower portion of the outer surface of the front end of the paint box is provided with pull rings. The paint spraying robot drives a rotary disk and cooling fan blades to rotate to generate air flow through rotation of a power shaft of the heat dissipation device and guide out heat, protects the working state of components and protects movable components against damage, and the paint spraying range of the robot can be expanded through the moving component.

Owner:蒋世豪

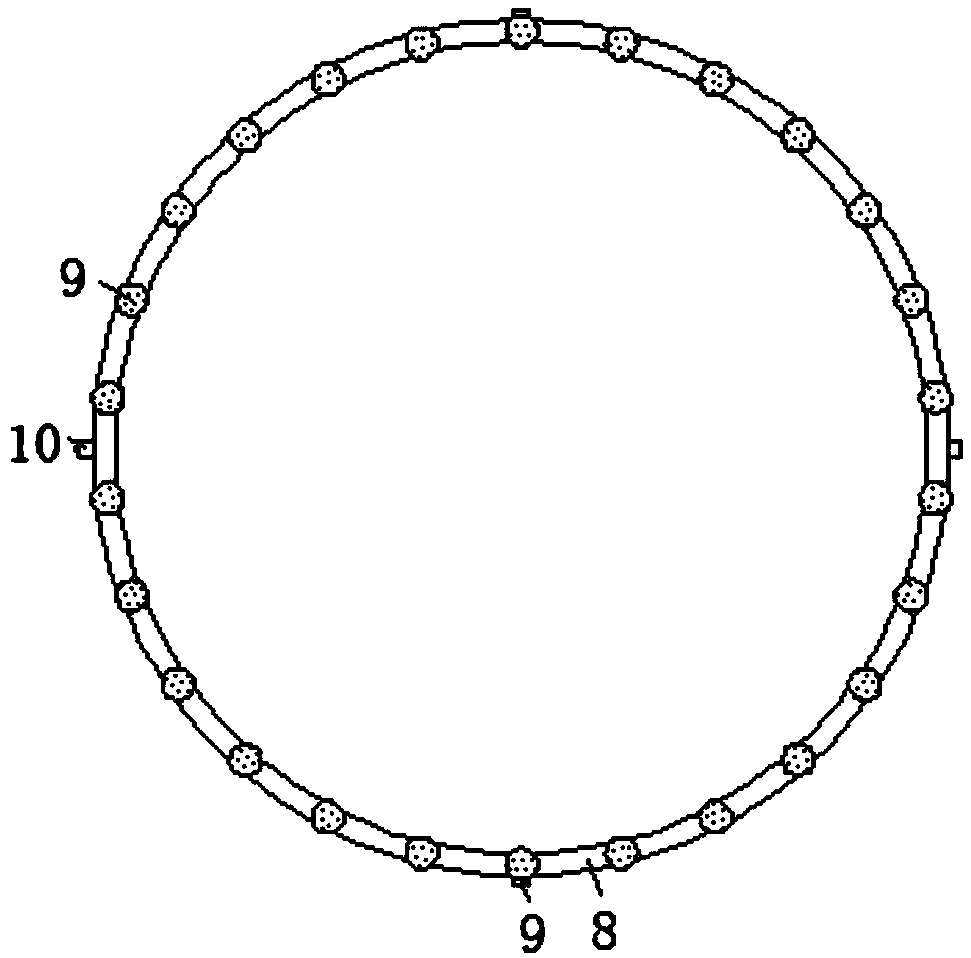

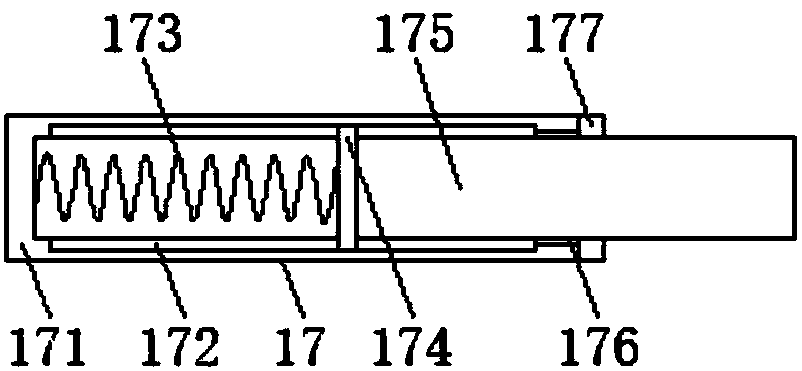

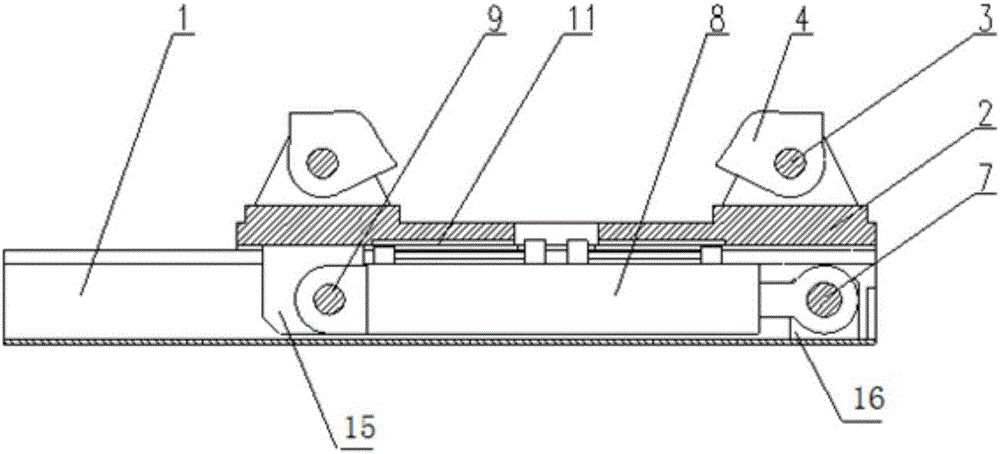

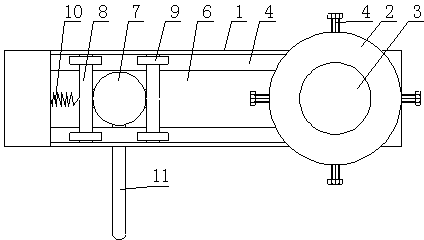

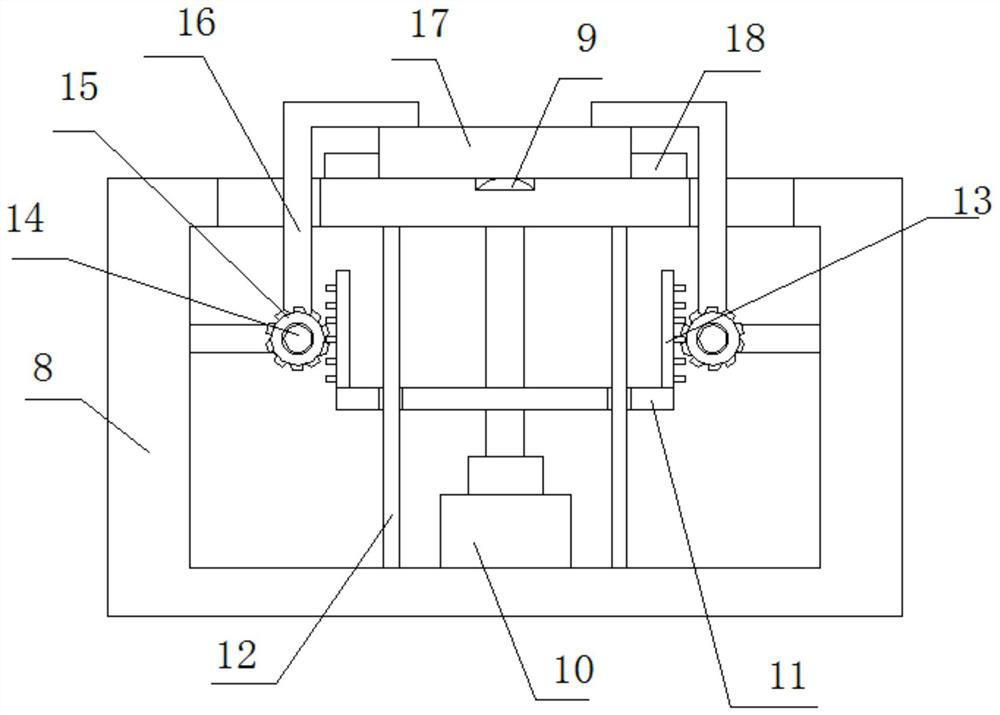

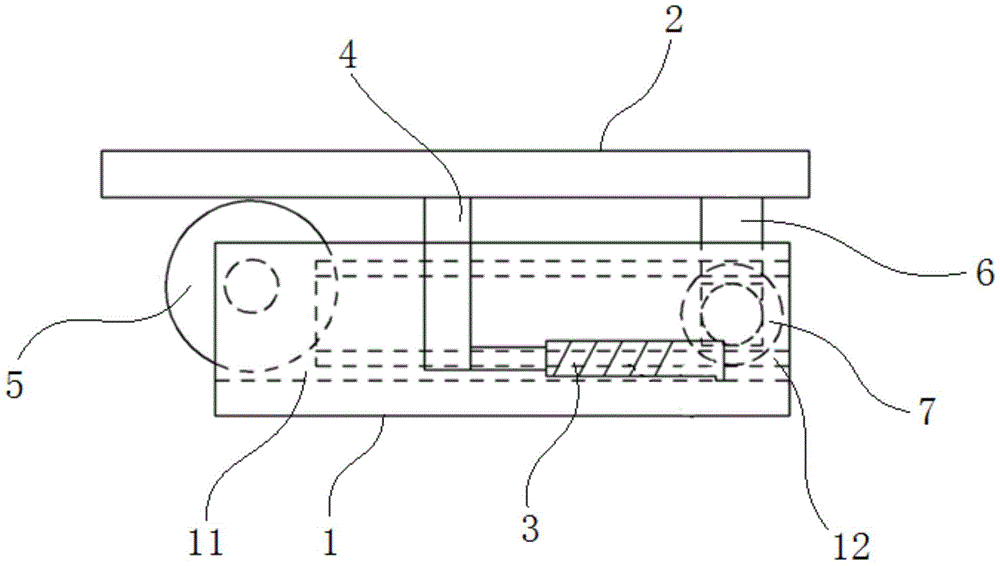

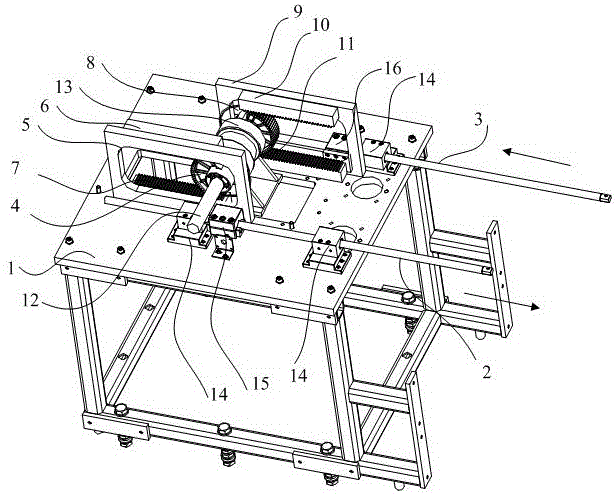

A two-for-one twister traverse device

ActiveCN105821533BSimple structureReduce running noiseContinuous wound-up machinesReciprocating motionWork Performances

The invention relates to a traversing gear of a two-for-one twister. The traversing gear comprises a mounting frame, a motor mounted on the mounting frame and a pair of traversing rods. The traversing gear of the two-for-one twister further comprises a pair of traversing frames, a rotary shaft driven by a motor, and a pair of half gears fixed to two ends of the rotary shaft respectively in a sleeving mode. Each traversing frame and the corresponding traversing rod are detachably fixed together and do reciprocating motion on the mounting frame. Each pair of racks sequentially engaged with the corresponding half gear are arranged in a vertically opposite mode and fixed to the corresponding traversing frame. The traversing gear of the two-for-one twister is simple and light in structure, low in running noise, low in energy consumption, low in cost and stable in traversing, the traversing stroke and traversing speed can be adjusted, the production efficiency and work performance of the two-for-one twister can be improved, and the product application range can be widened.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

The Construction Method of Long-span Reinforced Concrete Composite Truss Girder Lateral Movement and Beam Falling

The invention discloses a large-span steel concrete combined truss girder side position transverse movement and girder dropping construction method. The construction method comprises the following steps of (1) measuring whether two slide way girder axels to be parallel, (2) installing a pulling transverse-moving system, (3) conducting main point pilot transverse movement outside railway clearance, (4) locking the main point to conduct formal transverse movement construction according to the pilot transverse movement data, (5) installing a girder-dropping steel support pier, a temporary protection pier and a girder-dropping jack on a pier top cap after the girder body is transversely moved to a designed position, then detaching a slide boat, a spherical steel bearer and a slide way beam. In the second step, the pulling transverse-moving system comprises an upper slide way, a lower slide way and a traction device, wherein the upper slide way is formed by the spherical steel bearer and the slide boat; the lower slide way is formed by two slide way beams; the slide boat of the upper slide way is buckled on the lower slide way; the traction device is connected with the slide boat on the transverse-movement front end via a steel strand; in the fifth step, two ends of the beam body conduct alternative girder-dropping; the spherical steel bearer is mounted on the lower part of the beam body; the spherical steel bearer falls on a supporting pinner; and the girder-dropping is in place.

Owner:RAILWAY NO 10 ENG GRP CO LTD +1

A painting robot

ActiveCN108970869BExpand the scope of paintingSmooth traverseLiquid spraying apparatusPaint robotEngineering

The invention relates to the technical field of functional robots and discloses a paint spraying robot. The paint spraying robot comprises a supporting column. The lower end of the supporting column is provided with a first rotary shaft. A base is arranged under the first rotary shaft. Fixing bolts penetrate through the inner side of the base. A moving component is arranged on the outer surfaces of the lower ends of the fixing bolts. A heat dissipation device is arranged on the upper portion of the outer surface of the front end of the supporting column. The upper end of the heat dissipation device is provided with a telescopic outer rod. The outer surface of the upper end of the telescopic outer rod is provided with a fixed plate. The upper end of the fixed plate is provided with a paintbox. The lower portion of the outer surface of the front end of the paint box is provided with pull rings. The paint spraying robot drives a rotary disk and cooling fan blades to rotate to generate air flow through rotation of a power shaft of the heat dissipation device and guide out heat, protects the working state of components and protects movable components against damage, and the paint spraying range of the robot can be expanded through the moving component.

Owner:蒋世豪

Traversing type hydraulic rerailer

ActiveCN106428105BReduce local pressureOvercome the disadvantages of local stress concentrationDevices secured to trackStructural engineeringPiston

The invention discloses a transverse moving type hydraulic rerailer. A rerailing beam is in a groove-shaped structure with an upward opening, and two sliding rails are fixed to the top ends of two side plates of the rerailing beam in the full length; a moving table capable of sliding left and right is arranged on the sliding rails; a transverse moving cylinder is mounted in the groove-shaped structure, the right end of the transverse moving cylinder is hinged to the right end of the rerailing beam through a first pin shaft, and the left end of the transverse moving cylinder is hinged to the left end of the moving table through a second pin shaft; the bottom ends of two jacking cylinders arranged in a herringbone form are respectively hinged to the moving table through supporting pin shafts; and the piston ends of the two jacking cylinders are symmetrically hinged to positions under a jacking head, so that a triangular stable structure is formed by the moving table, the two jacking cylinder and the jacking head through mutual connection. According to the traverse moving type hydraulic rerailer disclosed by the invention, a jacking part adopts the triangular stable structure, and a traverse moving part adopts a sliding structure, so that not only is the stability of the rerailer during rerailing improved, but also the cost is reduced.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Traversing device for vehicle loading plate

The invention discloses an automobile carrying plate transverse shifting device which comprises a base, a sliding rack, at least one support wheel and a hydraulic cylinder, wherein an automobile carrying plate sliding groove is formed in the base in a concave manner; the upper end of the sliding rack is fixedly arranged at the rear end of the automobile carrying plate; a roller which can walk inside the automobile carrying plate sliding groove is arranged at the lower end of the sliding rack; the at least one support wheel is arranged at the front end of the automobile carrying plate sliding groove in a rotational manner; the support wheel is supported at the bottom of the automobile carrying plate; the hydraulic cylinder is connected with the automobile carrying plate so as to drive the automobile carrying plate to move. Preferably, two guide grooves are respectively formed in two side walls of the automobile carrying plate sliding groove in a concave manner, and two rollers which are respectively moveably clamped inside the two guide grooves are respectively arranged at the lower end of the sliding rack; the one support wheel which is barrel-shaped is arranged or the two support wheels are respectively arranged at the front ends of the two side walls of the automobile carrying plate sliding groove. The automobile carrying plate transverse shifting device is capable of driving the automobile carrying plate to move stably, and is simple in structure, convenient to maintain and long in service life.

Owner:GUANGXI UNIV

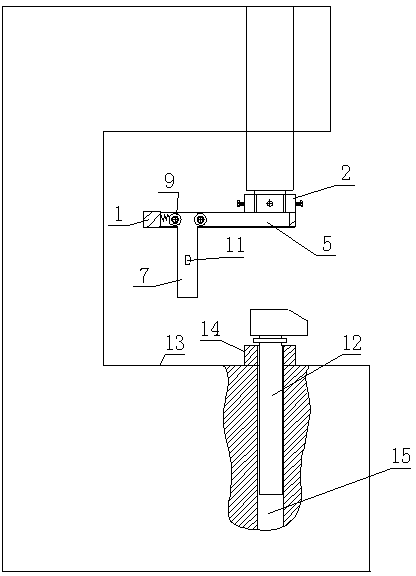

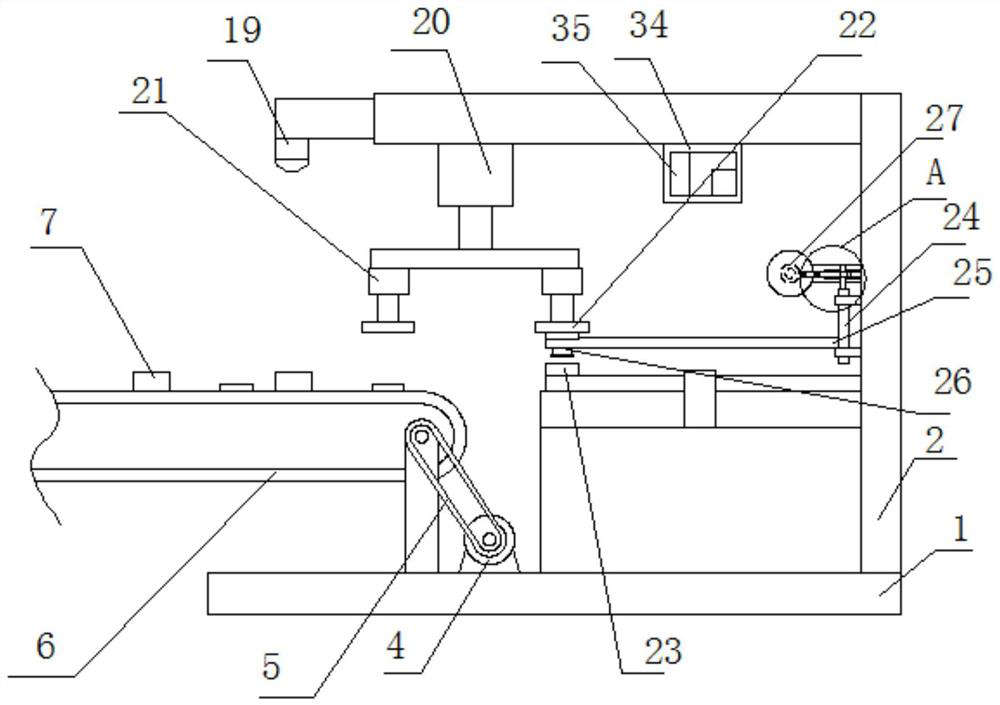

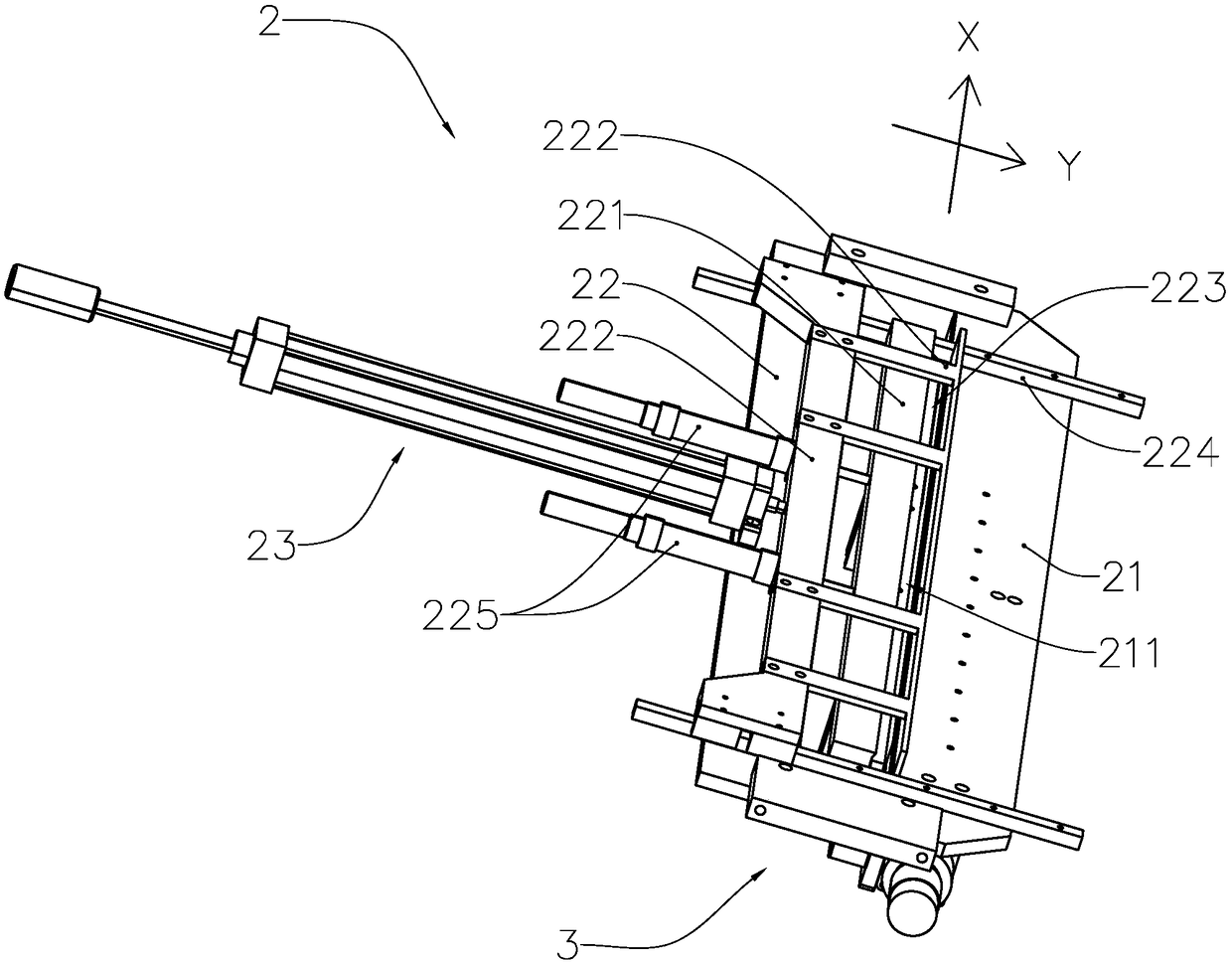

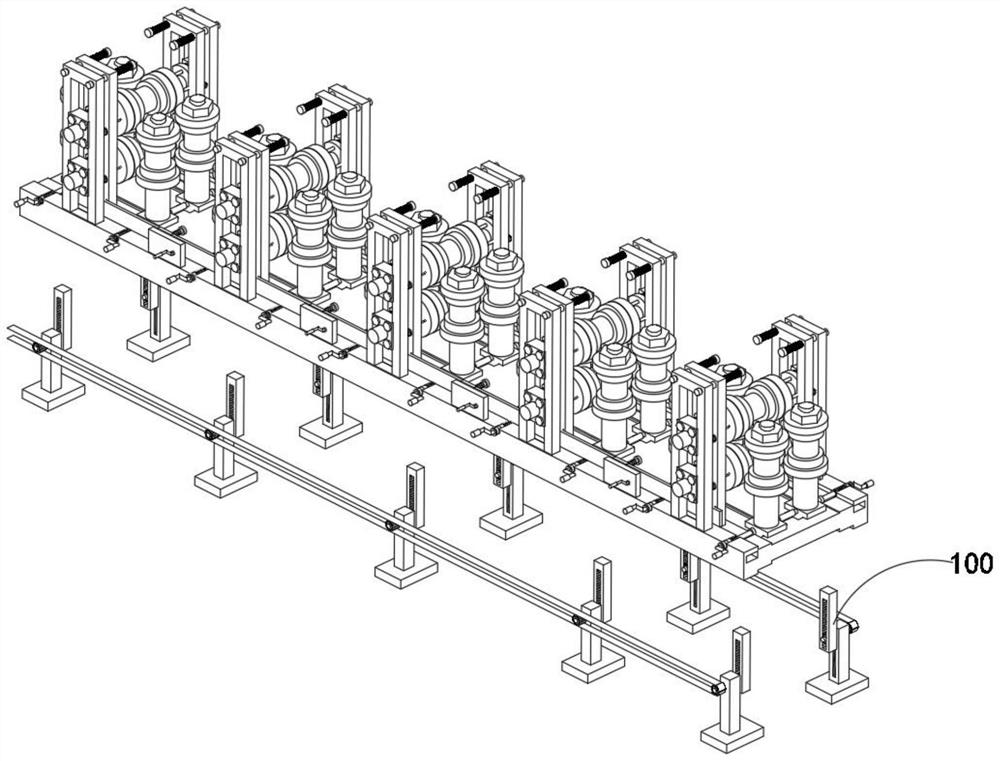

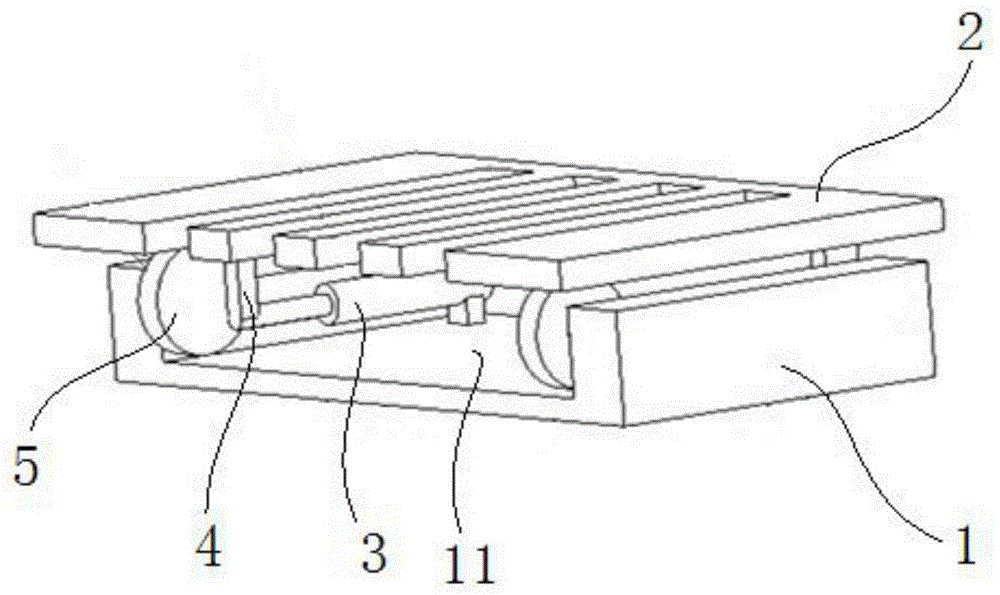

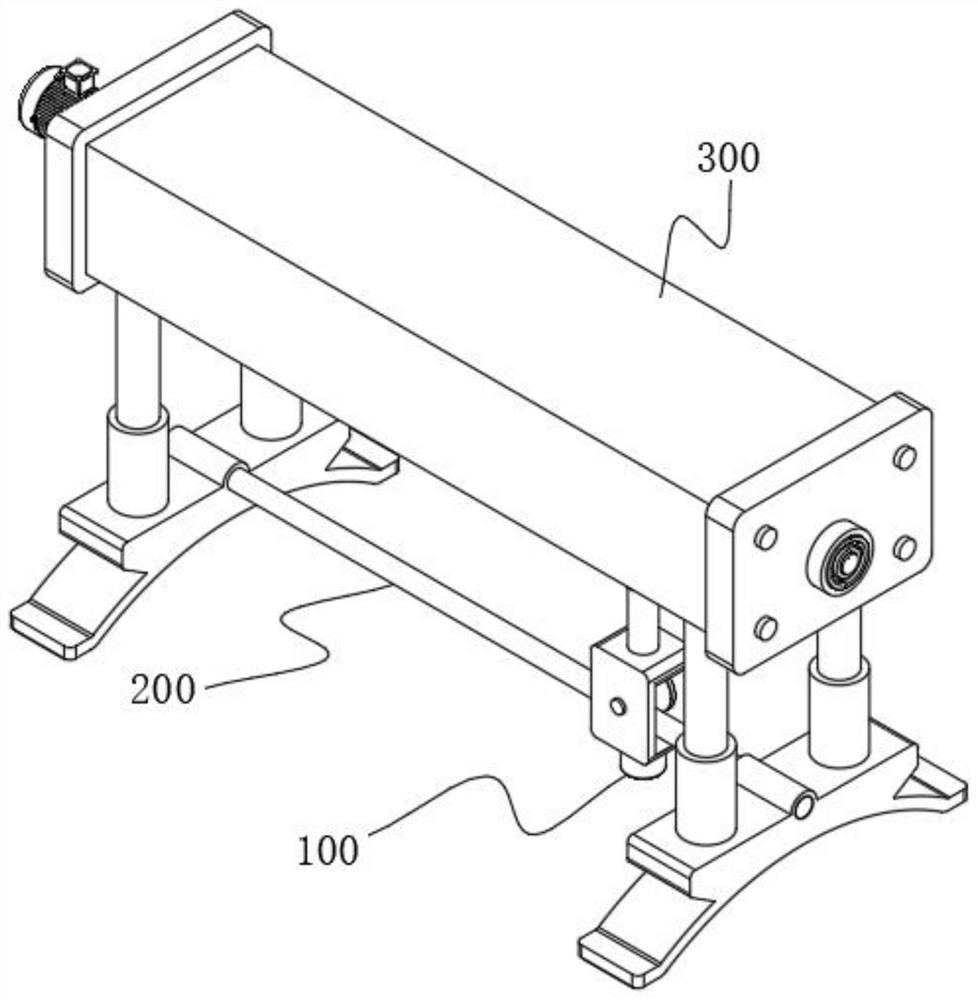

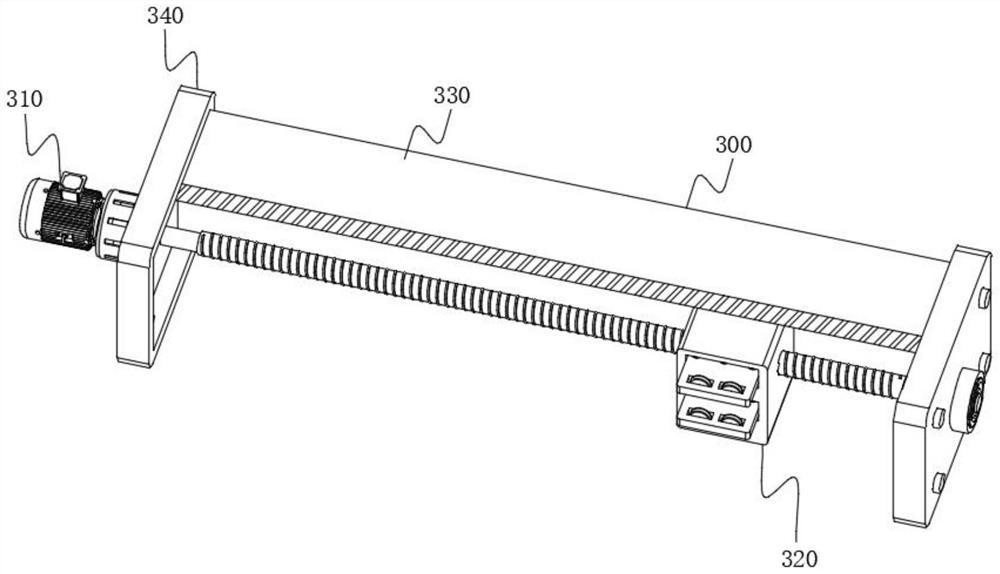

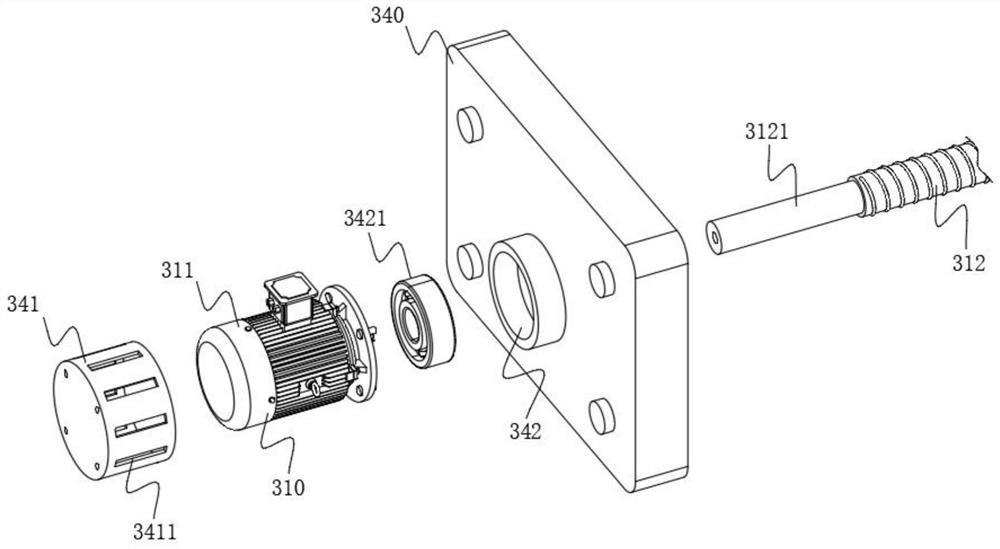

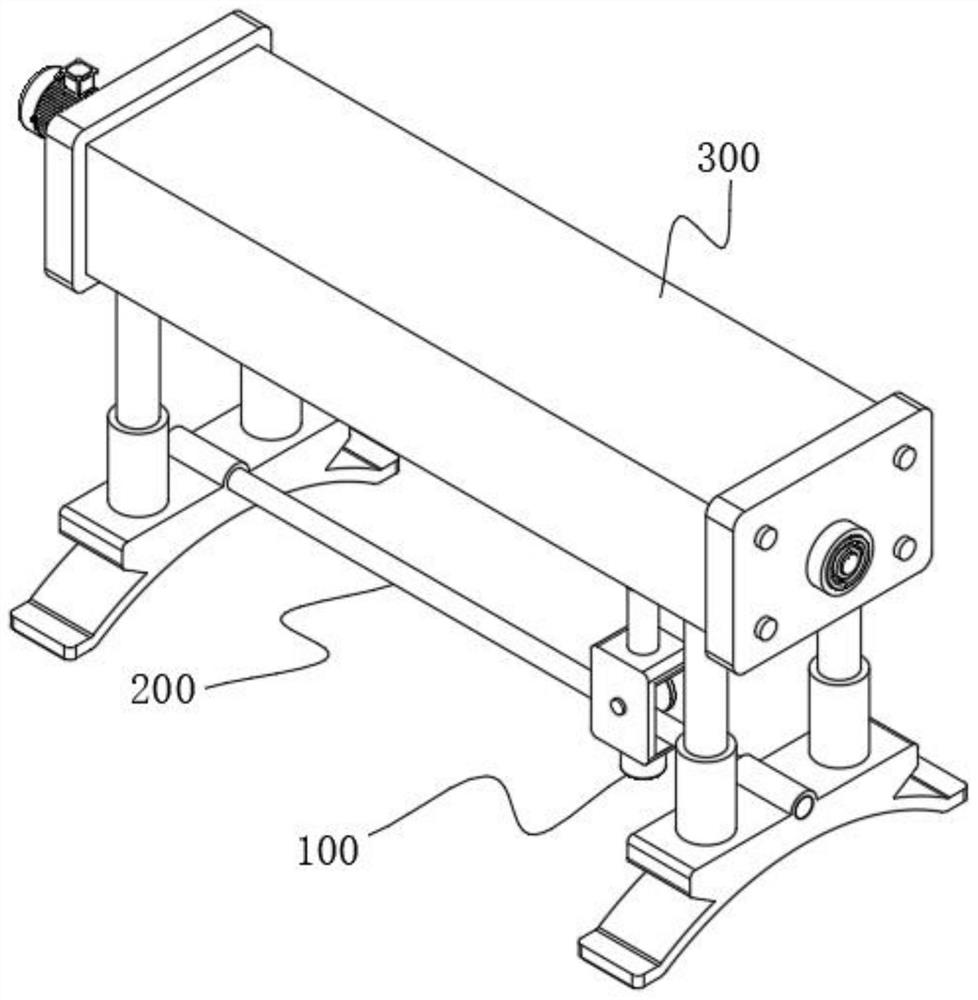

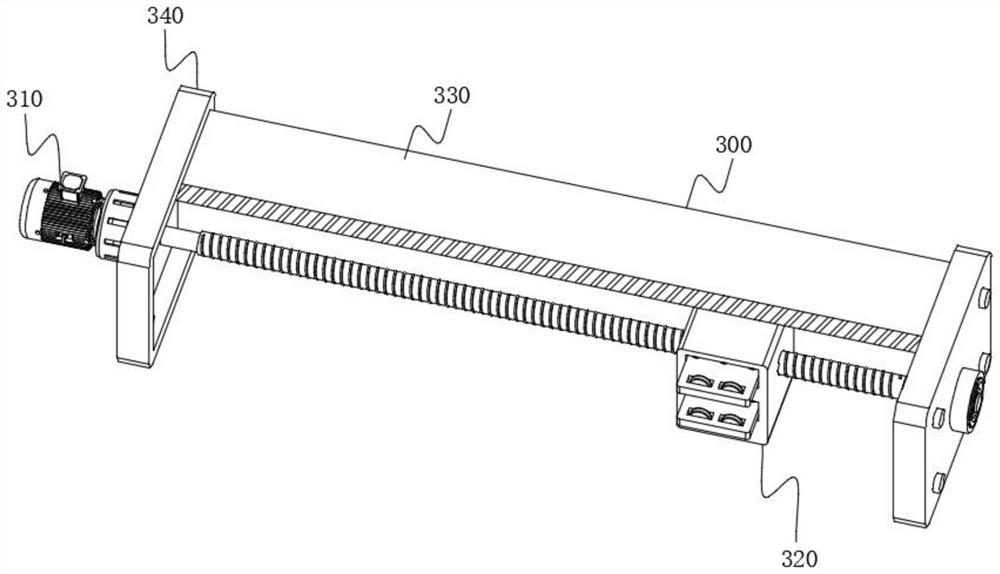

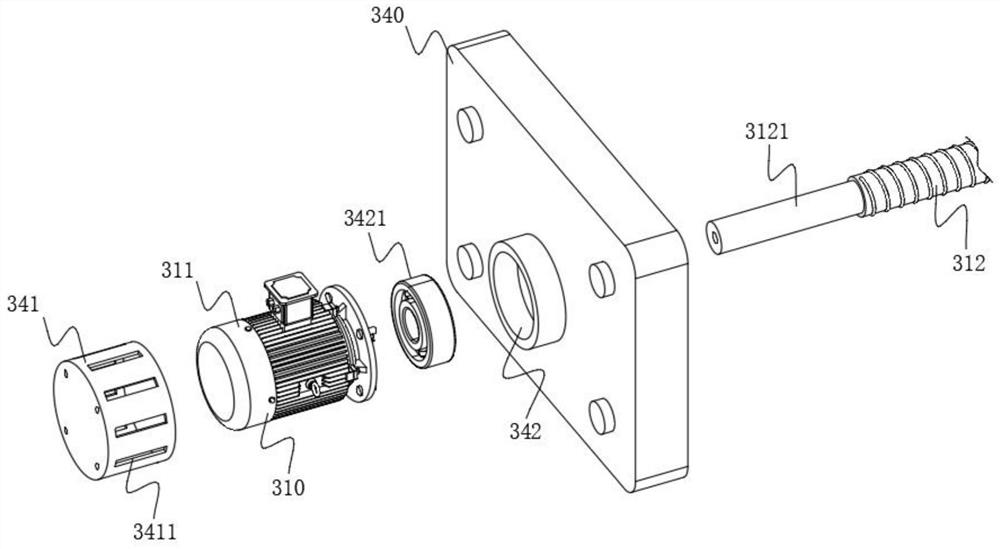

A Friction Welding Spindle Head Based on Support Rod Lateral Movement

ActiveCN112276334BSmooth traverseAchieve separationNon-electric welding apparatusFriction weldingElectric machinery

The invention relates to the technical field of friction welding, in particular to a friction welding spindle head based on a support bar type lateral movement. It includes a spindle head, a traversing mechanism and a transmission mechanism arranged on the top of the traversing mechanism. The traversing mechanism includes a support rod, and both ends of the support rod are provided with support seats, and the support seats include support blocks. The middle position of the top of the support block is provided with an insertion hole, and the support rod is plugged and matched with the insertion hole. The top of the support block is provided with a support rod. The transmission mechanism includes a power device, and the power The device includes a motor, and a screw rod is arranged on the left side of the motor. In the present invention, the set motor drives the screw to rotate, and drives the transmission block and the traverse block to move, and the traverse block moves to drive the spindle head at the bottom to move, thereby realizing the separation of the spindle head and the motor, and then reducing the vibration of the motor to the spindle head. Impact.

Owner:湖南坤鼎数控科技有限公司

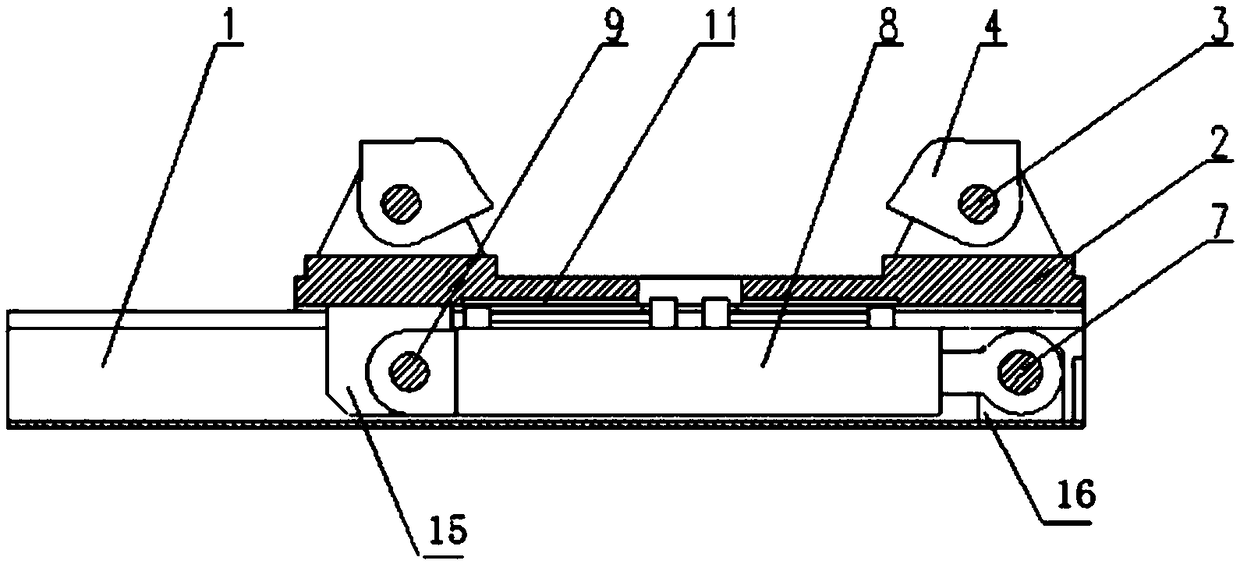

Friction welding spindle head based on support rod type transverse movement

ActiveCN112276334ASmooth traverseAchieve separationNon-electric welding apparatusFriction weldingMotor vibration

The invention relates to the technical field of friction welding, in particular to a friction welding spindle head based on support rod type transverse movement. The friction welding spindle head comprises a spindle head, a transverse moving mechanism and a transmission mechanism arranged on the top of the transverse moving mechanism, wherein the transverse moving mechanism comprises a support rod; the two ends of the support rod are equipped with supporting bases; each supporting base comprises a supporting block, a splicing hole is formed in the middle position of the top of the supporting block, and the support rod is in splicing fit to the splicing hole; a supporting rod is arranged on the top of each supporting block; the transmission mechanism comprises a power device which comprisesa motor; and the left side of the motor is equipped with a lead screw. The motor drives the lead screw to rotate, and drives a transmission block and a transverse moving block to move, and the transverse moving block drives a spindle head on the bottom to move, so that separation of the spindle head and the motor is realized, and influences, on the spindle head, of motor vibration are reduced.

Owner:湖南坤鼎数控科技有限公司

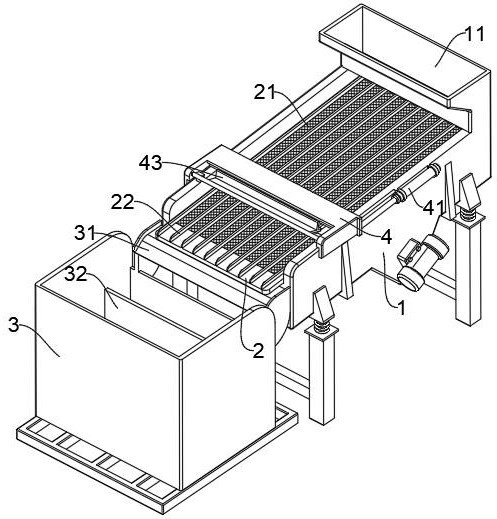

A blow-selection type flaky bamboo wood shavings sorting device

The invention discloses a blowing type flaky bamboo shavings sorting device, which comprises a linear vibrating screen, an inclined vibrating plate is arranged on the linear vibrating screen, the vibrating plate comprises a screen mesh, and the vibrating plate is provided with an inclined vibrating plate. Several orientation strips extending along the discharge direction, the orientation strips are located on the upper side of the screen. The present invention performs preliminary screening through a linear vibrating screen to screen out impurities such as debris, sand and gravel in the shavings to ensure quality. At the same time of screening, directional strips are set up, and through the vibration of the vibrating screen and the limiting effect of the directional strips, the long strips are oriented and arranged so that the shavings can be discharged neatly. The contact surface of the oriented shavings and the airflow is more uniform, and the impelling force of the airflow is more stable, so that the shavings of different thicknesses or different thicknesses have different degrees of stable lateral movement under the action of the airflow, and then pass through different air flow. Storage chamber for collection for precise sorting.

Owner:TREEZO NEW MATERIAL TECH GRP CO LTD

Circuit board soldering device for controller production

ActiveCN113365437BMove preciselySmooth traversePrinted circuit assemblingWelding/cutting auxillary devicesGear wheelEngineering

The invention discloses a circuit board soldering device for controller production, comprising a control combination, a second fitting mechanism, a first fitting mechanism, a lifting combination, a fixing mechanism and a spot welding assembly. The control combination comprises a protective outer frame, and the second The accessory mechanism includes a pressing combination, and the pressing combination comprises a second sliding block and a spring buckle mounted on the top of the second sliding block. The limit slots of the first rocker and the second rocker on the base and the T-shaped slider at the bottom of the base can ensure that the electronic components fixed on the pressing combination and the coordination combination can be accurately aligned with the bottom surface of the printed circuit board At the same time, the electronic components are pressed by the electromagnet piece, the permanent magnet piece, the first sliding piece and the pressing piece. When the tooth slot on one side moves, it ensures that the electronic components used for spot welding will not be subject to the problem of partial rollover caused by the shaking of the artificial hand.

Owner:徐州科悦电子科技有限公司

Traversing gear of two-for-one twister

ActiveCN105821533ASimple structureReduce running noiseContinuous wound-up machinesWork performanceReciprocating motion

The invention relates to a traversing gear of a two-for-one twister. The traversing gear comprises a mounting frame, a motor mounted on the mounting frame and a pair of traversing rods. The traversing gear of the two-for-one twister further comprises a pair of traversing frames, a rotary shaft driven by a motor, and a pair of half gears fixed to two ends of the rotary shaft respectively in a sleeving mode. Each traversing frame and the corresponding traversing rod are detachably fixed together and do reciprocating motion on the mounting frame. Each pair of racks sequentially engaged with the corresponding half gear are arranged in a vertically opposite mode and fixed to the corresponding traversing frame. The traversing gear of the two-for-one twister is simple and light in structure, low in running noise, low in energy consumption, low in cost and stable in traversing, the traversing stroke and traversing speed can be adjusted, the production efficiency and work performance of the two-for-one twister can be improved, and the product application range can be widened.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com