Traverse moving type hydraulic rerailer

A rerailing device and traversing technology, which is applied to the equipment fixed to the track, railway car body parts, transportation and packaging, etc. problems, to achieve the effect of improving safety and stability, reducing strength requirements, and overcoming local stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

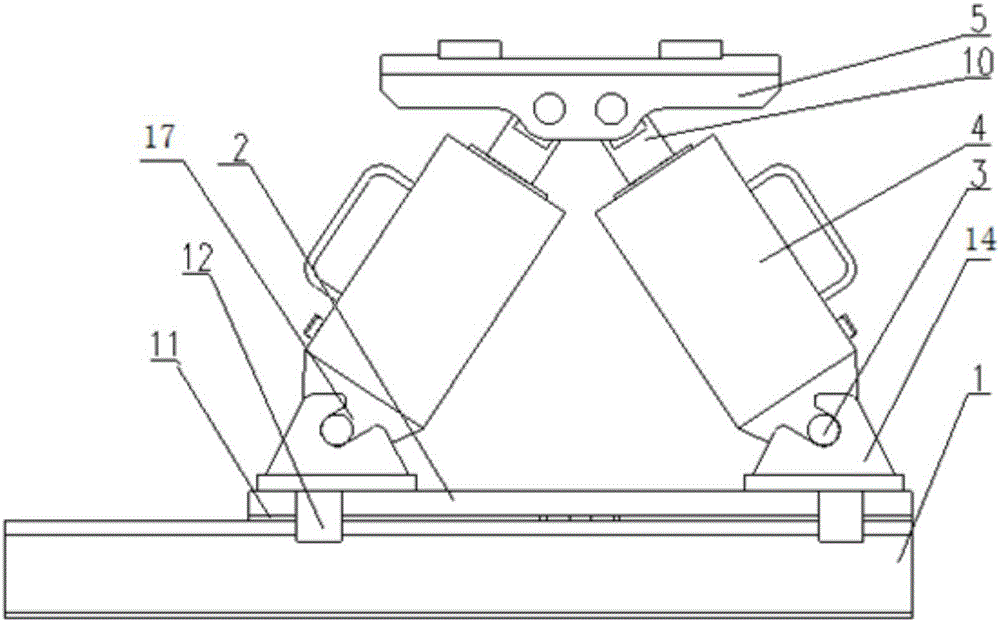

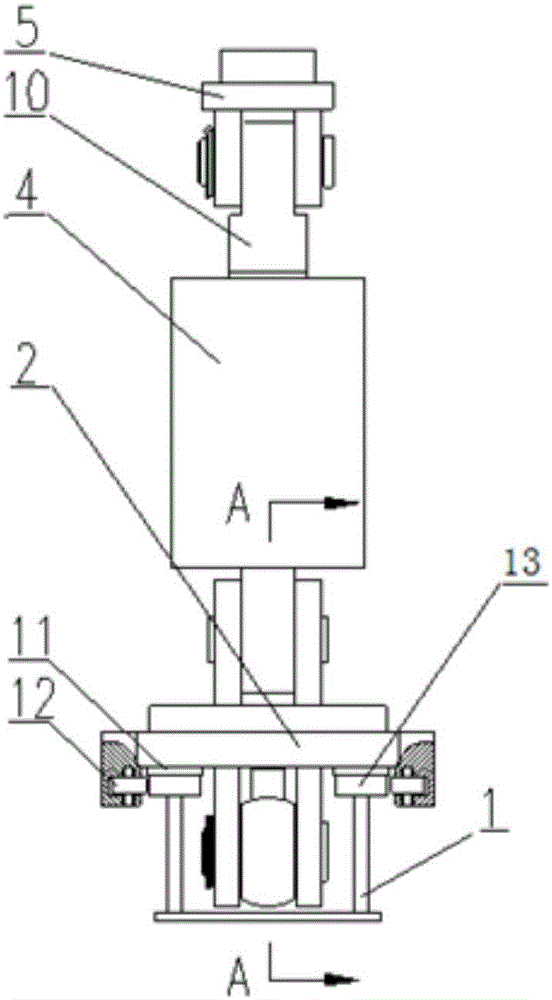

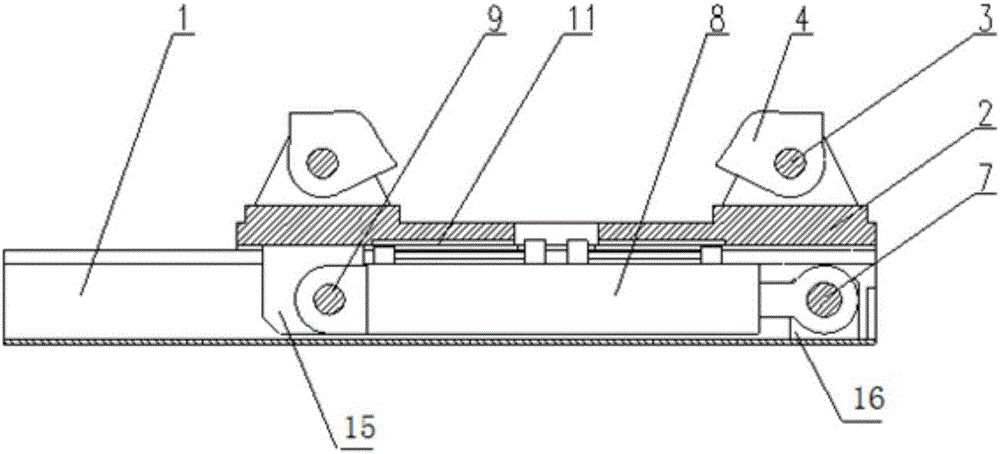

[0016] Attached below Figure 1-4 Describes an embodiment of the invention

[0017] A traverse type hydraulic rerailing device, comprising a rerailing beam 1, the rerailing beam 1 is a trough-shaped structure with an opening facing upwards, and two slide rails 13 are fixed on the top of both side plates. The rail 13 is provided with a mobile platform 2 that can slide left and right; the traversing oil cylinder 8 is housed in the groove structure, and the first connecting plate 15 is fixed at the middle position of the left end of the lower end surface of the mobile platform 2, and the first connecting plate 15 Extending downward into the groove structure of the rerailing beam 1, the second connecting plate 16 is fixed in the groove structure at the right end of the rerailing beam 1, and the right end of the traverse cylinder 8 passes through the first pin shaft 7 and the second connecting plate 16 Hinged, the left end of the traverse oil cylinder 8 is hinged with the first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com