Circuit board soldering device for controller production

A technology for controllers and circuit boards, applied in the direction of assembling printed circuits, printed circuits, auxiliary devices, etc. with electrical components, can solve problems such as damage to the surface of circuit boards, and achieve the effect of improving safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

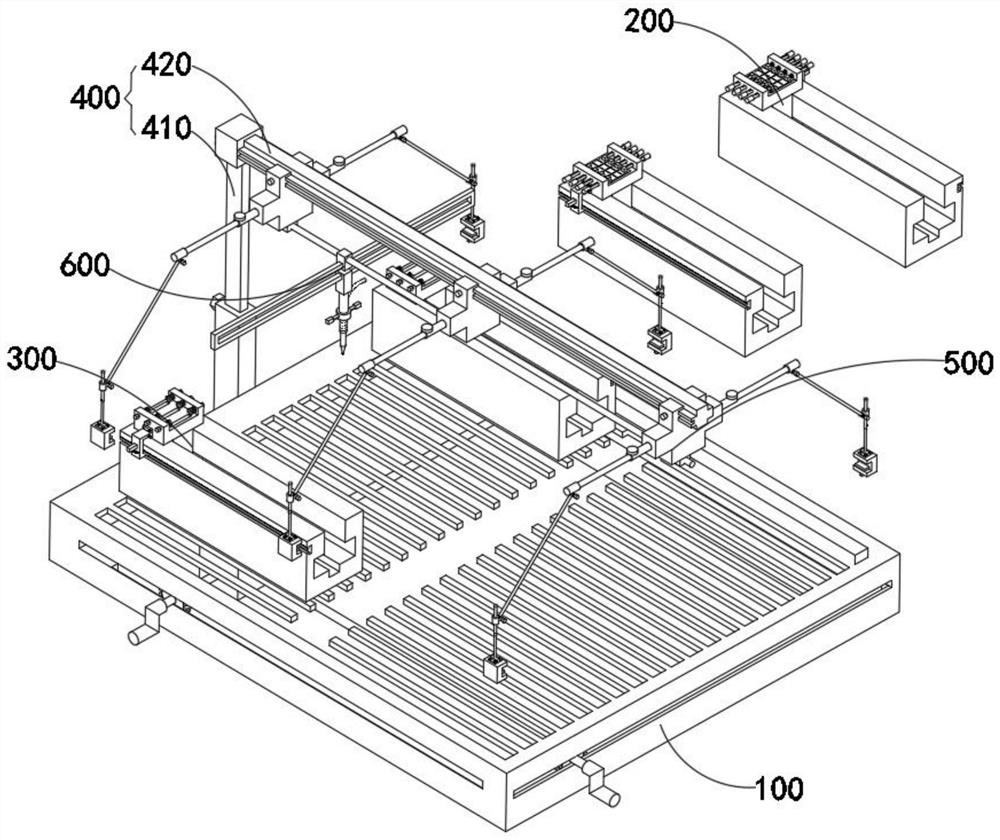

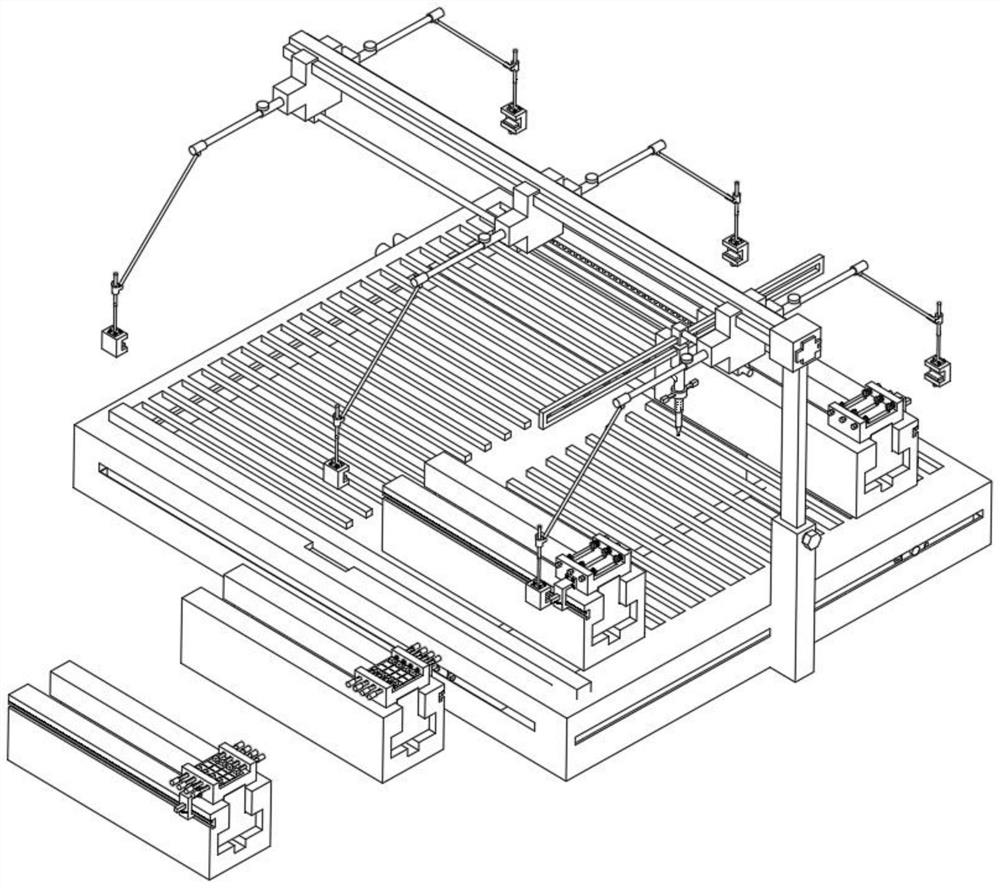

[0056] combine figure 1 , 4 , 7, 12 and 14, the circuit board soldering device for controller production provided by the present invention includes a control combination 100, a second accessory mechanism 200, a first accessory mechanism 300, a lifting combination 400, a fixing mechanism 500 and a spot welding assembly 600, wherein, the lifting assembly 400 is fixedly installed on the outside of the protective outer frame 110 inside the control assembly 100 through its internal lifting pile 410, and the second accessory mechanism 200 and the first accessory mechanism 300 can both pass through the forehead located in the control assembly 100 The T-shaped slider is inserted above the control combination 100, while the fixing mechanism 500 is movably installed on the lifting combination 400 through its internal fixing block 510. In addition, the spot welding assembly 600 is installed on the fixing mechanism 500 through its internal slide bar 610. superior.

[0057] The control a...

Embodiment 2

[0062] As shown in 9, in the above embodiment, slot holes are provided in the middle of the four edges of the protective outer frame 110, and two ends of the first rocker 130 and the second rocker 140 are installed at the same time. The gear of the bar 120 can make the base 210 and the base 310 carry out precise displacement and movement by utilizing the stable movement of the upper gears of the first rocker 130 and the second rocker 140 in the inner teeth of the rack 120. The control combination 100 also includes a The rack 120 in the slot on the inner edge of the protective frame 110 , the first rocker 130 connected in the protective frame 110 , and the second rocker 140 adapted to be installed in the inner cavity of the protective frame 110 .

Embodiment 3

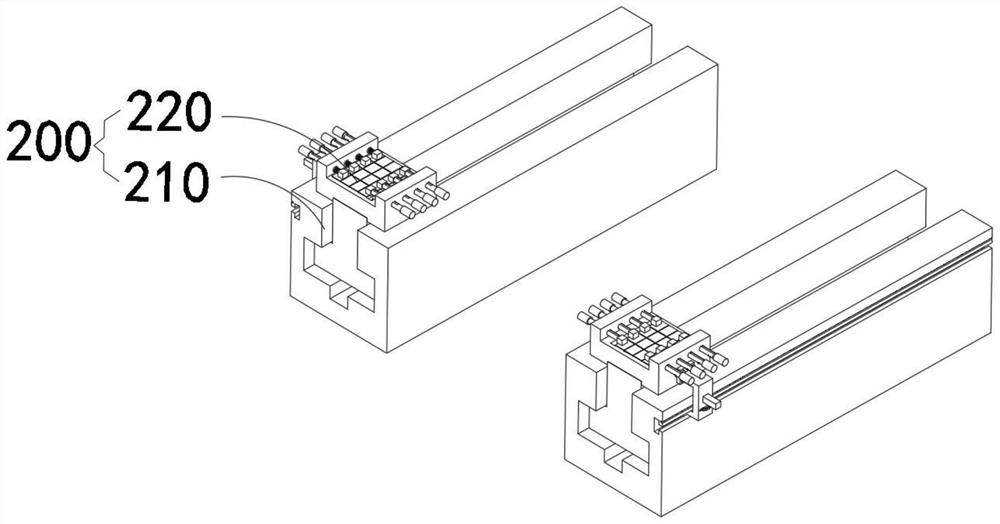

[0064] combine image 3 and 9 As shown, in the above embodiment, the base 210 and the rectangular hole at the bottom of the base 310 are connected to the chute on the top of the protective frame 110 through a T-shaped slider, and combined with the practical method of pressing the internal components of the assembly 220, the base is set 210 is inserted on the T-shaped slider, which can assist the internal parts of the compression combination 220 to quickly move different electronic components under the component surface at the bottom of the circuit board. By setting the base 310 and the coordination combination 320, the resistance in the electronic components The limit is fixed, which can make the silver corner of the bent resistor and its whole be fixed smoothly, and at the same time, under the action of the bar-shaped rack in the outer chute of the base 310, the fixed resistor can be accurately adapted to the position of the pad. At the same time, T-shaped sliders are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com