Construction method for horizontal moving beam of double-track trolley

A double-track, trolley technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of restricting the reverse transportation and loading of prefabricated beams, affecting the production capacity of prefabricated beam factories, and slow running speed, saving labor and T beams. The traverse process is safe and the effect of reducing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

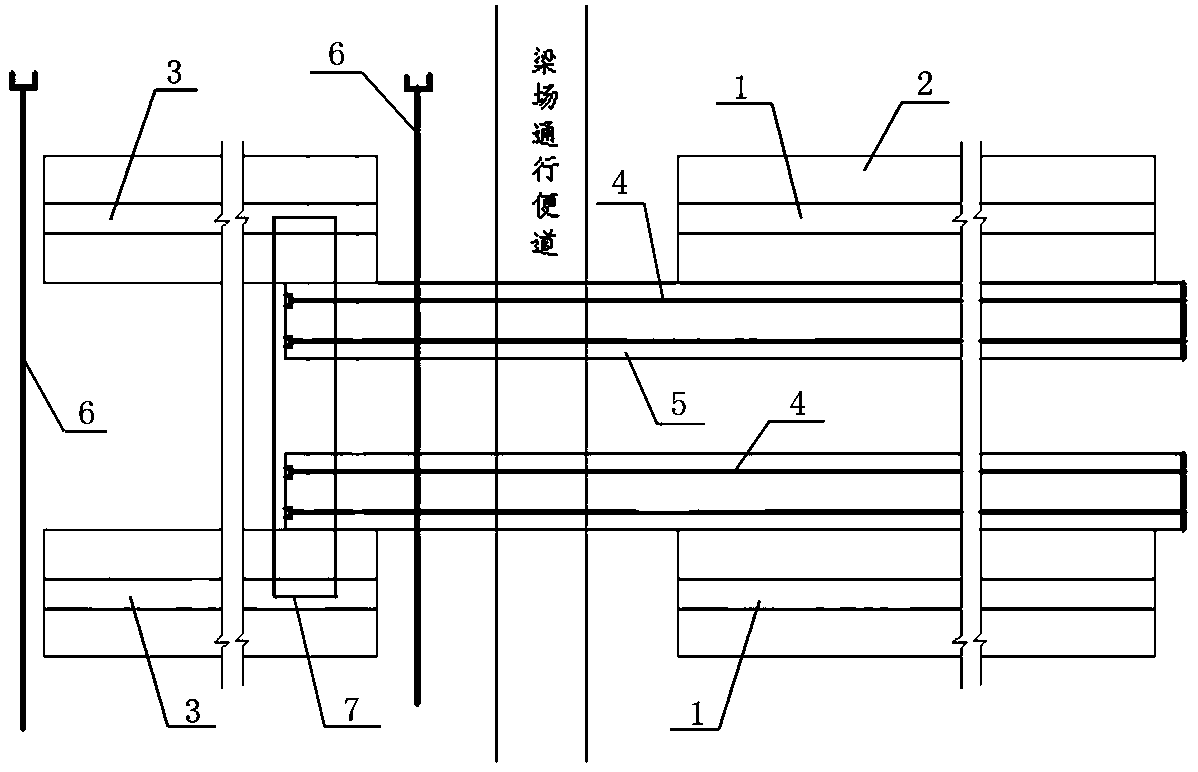

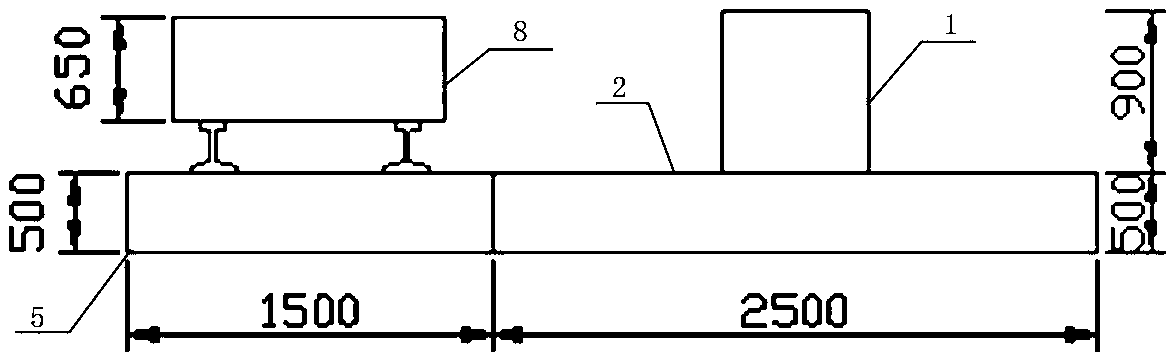

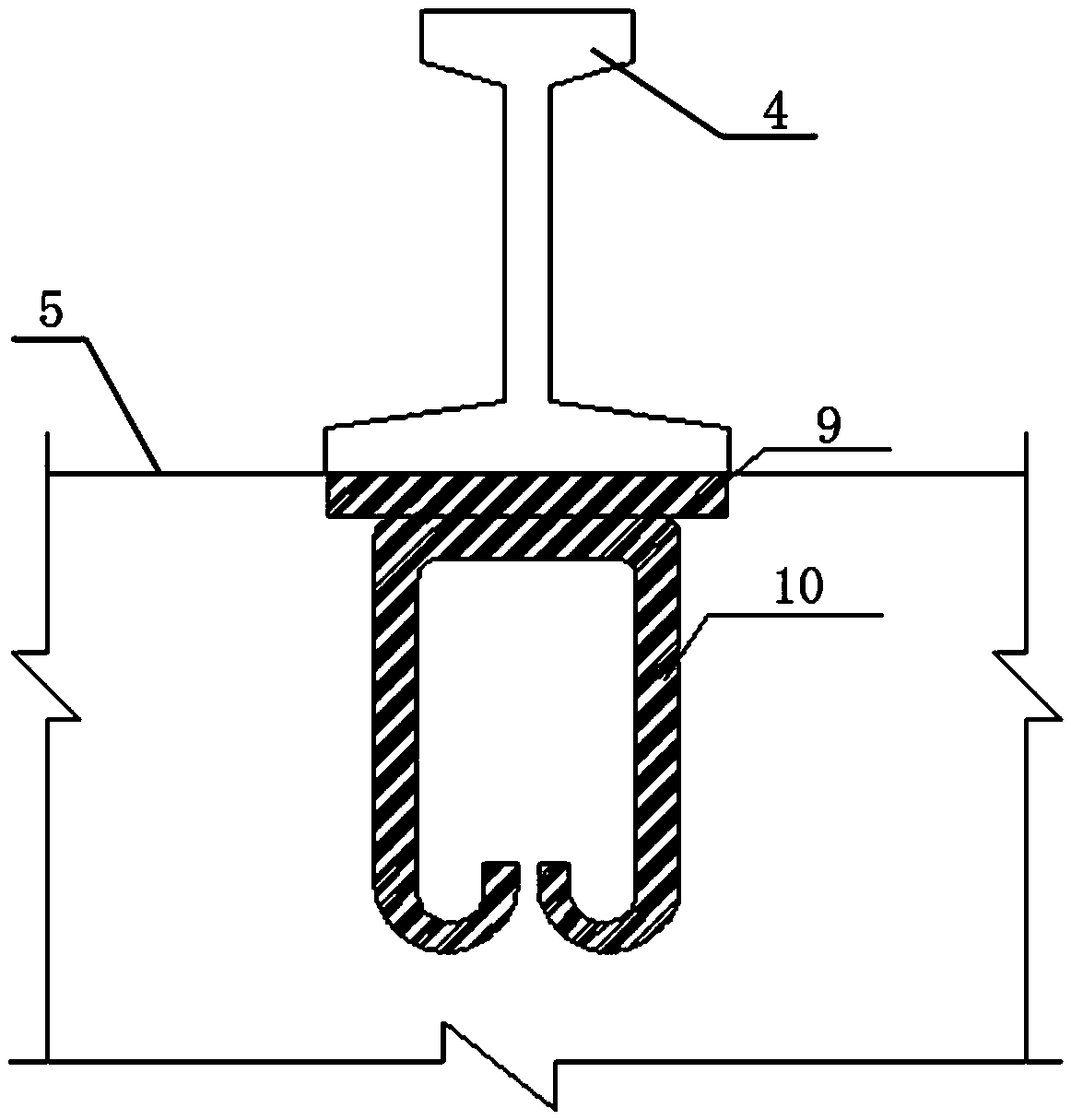

[0029] The process flow and key points of operation of the method of the present invention are described in detail.

[0030] Technological process: pedestal and track foundation construction → track installation → beam moving trolley installation → horizontal beam moving.

[0031] Platform and track foundation construction

[0032] 1. Construction process

[0033] Surveying and setting out→excavation of foundation pit→foundation bearing capacity inspection→installation of face protection reinforcement and embedded parts→mold clamping reinforcement→foundation concrete pouring→pedestal reinforcement frame binding→formwork reinforcement→pedestal concrete pouring→concrete curing.

[0034] 2. Measurement and setting out

[0035] 1) Positional relationship

[0036] The newly-built horizontal beam storage pedestal 1 is parallel to the existing longitudinal beam storage pedestal 3, and the transverse rail 4 is arranged on the inner side of the horizontal beam storage pedestal 1 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com