Auxiliary calibration mechanism for special-shaped steel processing

A calibration mechanism and special-shaped steel technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as insufficient calibration, and achieve the effect of improving stability and convenient and rapid replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

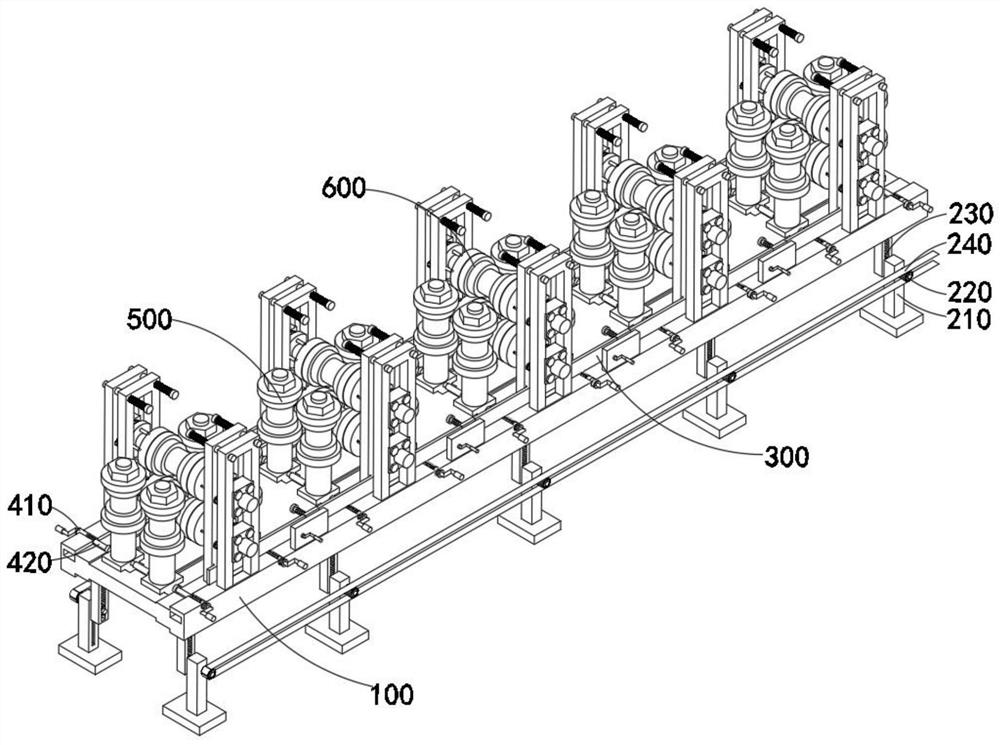

[0056] combine figure 1 , 4 , 6, 9, 10 and 12, the auxiliary calibration mechanism for special-shaped steel processing provided by the present invention includes a support mechanism 100, a lifting mechanism 200, a propulsion mechanism 300, a fine-tuning assembly 400, a vertical restraint mechanism 500 and a special-shaped steel calibration mechanism 600, wherein the lifting mechanism 200 is installed on the support mechanism 100, and the propulsion mechanism 300 is movably installed on the support mechanism 100, the fine-tuning assembly 400 is welded in the support mechanism 100, in addition, the vertical constraint mechanism 500 is movably installed in the support mechanism 100 In the chute, the special-shaped steel calibration mechanism 600 is fixedly installed on the support mechanism 100 .

[0057] The support mechanism 100 includes a working surface 110 and a riser 120, the lifting mechanism 200 includes a base 210, a shaft rod 220, a leg 230 and a chain 240, and the pro...

Embodiment 2

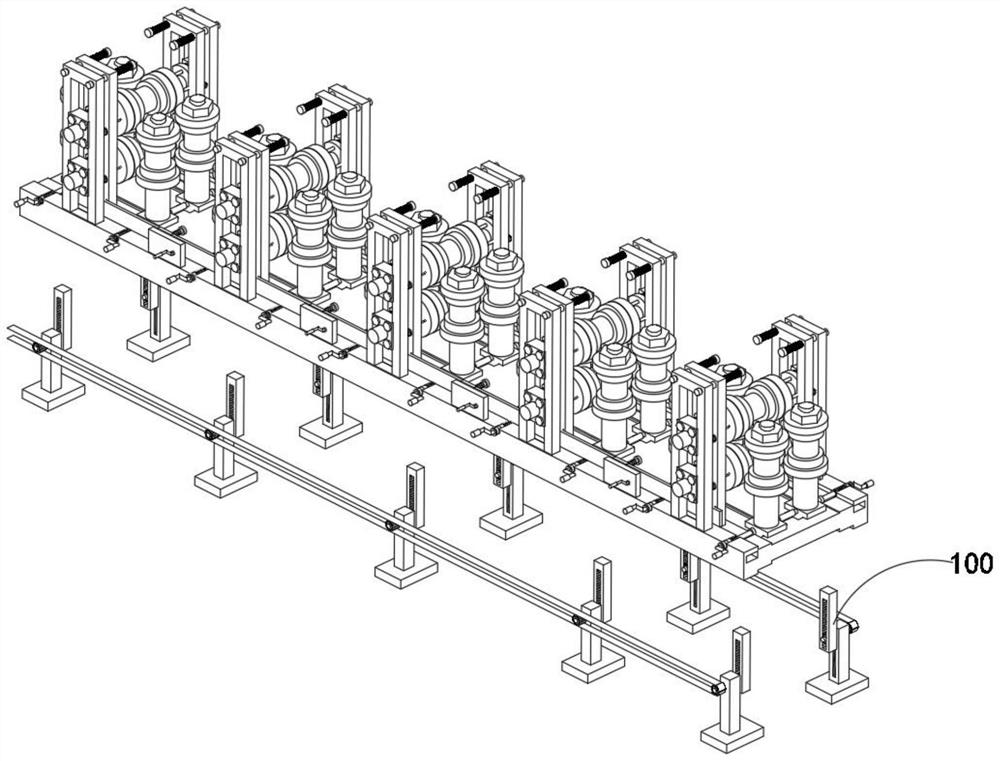

[0060] combine figure 1 As shown, in the above-mentioned embodiment, by fixing the riser 120 on both sides of the top of the worktable surface 110, when the rocker on the deflection toothed plate 360 penetrates to the outside of the riser 120, it is constrained by the support of the riser 120, At this time, the deflection toothed plate 360 can stably drive the external pull rod and promote the rotation of the screw rod 340. The support mechanism 100 also includes vertical plates 120 evenly installed on both sides of the top of the worktable 110, and the vertical plates 120 have built-in through holes.

Embodiment 3

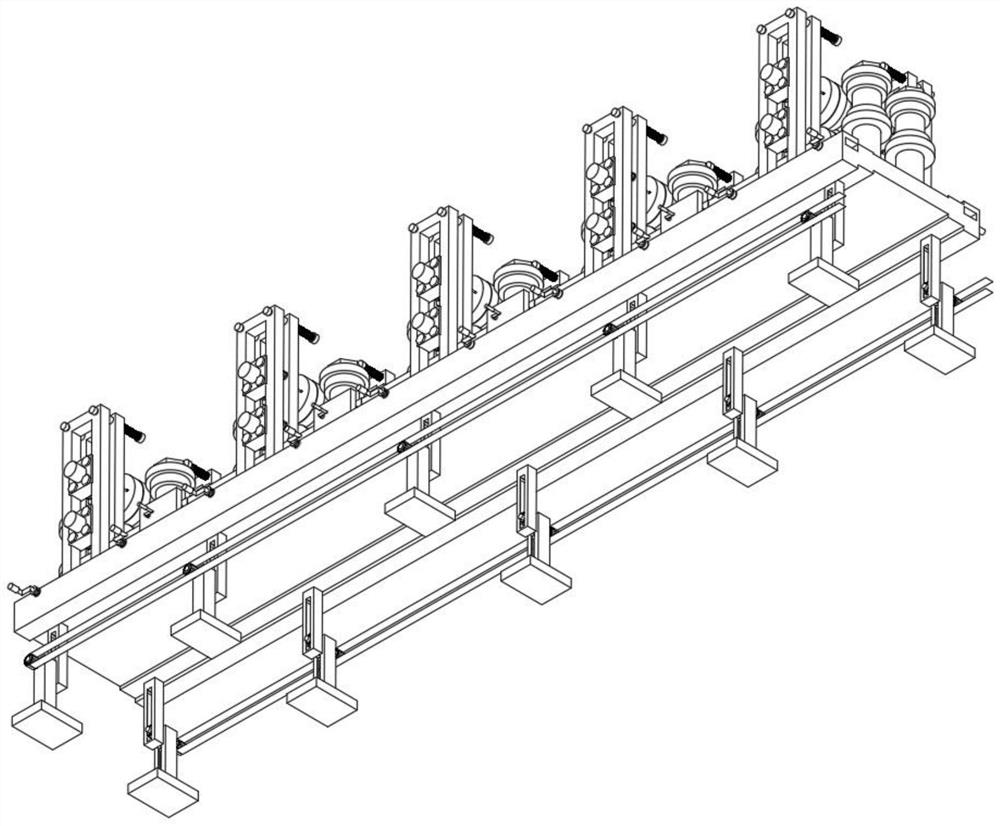

[0062] combine Figure 4 As shown, in the above-mentioned embodiment, the evenly distributed legs 230 are installed on the bottom of the work surface 110, and the base 210 is movably installed on the sliders outside the legs 230, and the shaft rod located in the inner notch of the legs 230 is used to The rotation of 220 drives the lifting and lowering of the supporting leg 230. At this time, the working table 110 of the device can quickly be in a horizontal parallel state with the existing machine tool. The lifting mechanism 200 includes the supporting leg 230 installed at the bottom of the working table The base 210 outside the legs 230 and the shaft 220 inside the base 210 and the chain 240 engaged at the outer end of the shaft 220 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com