A Friction Welding Spindle Head Based on Support Rod Lateral Movement

A technology of lateral movement and spindle head, applied in the field of friction welding, can solve the problems of not being able to achieve a constant state, reducing the quality of friction welding, and vibration of the motor, and achieving the effects of reducing temperature, improving stability, and increasing load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

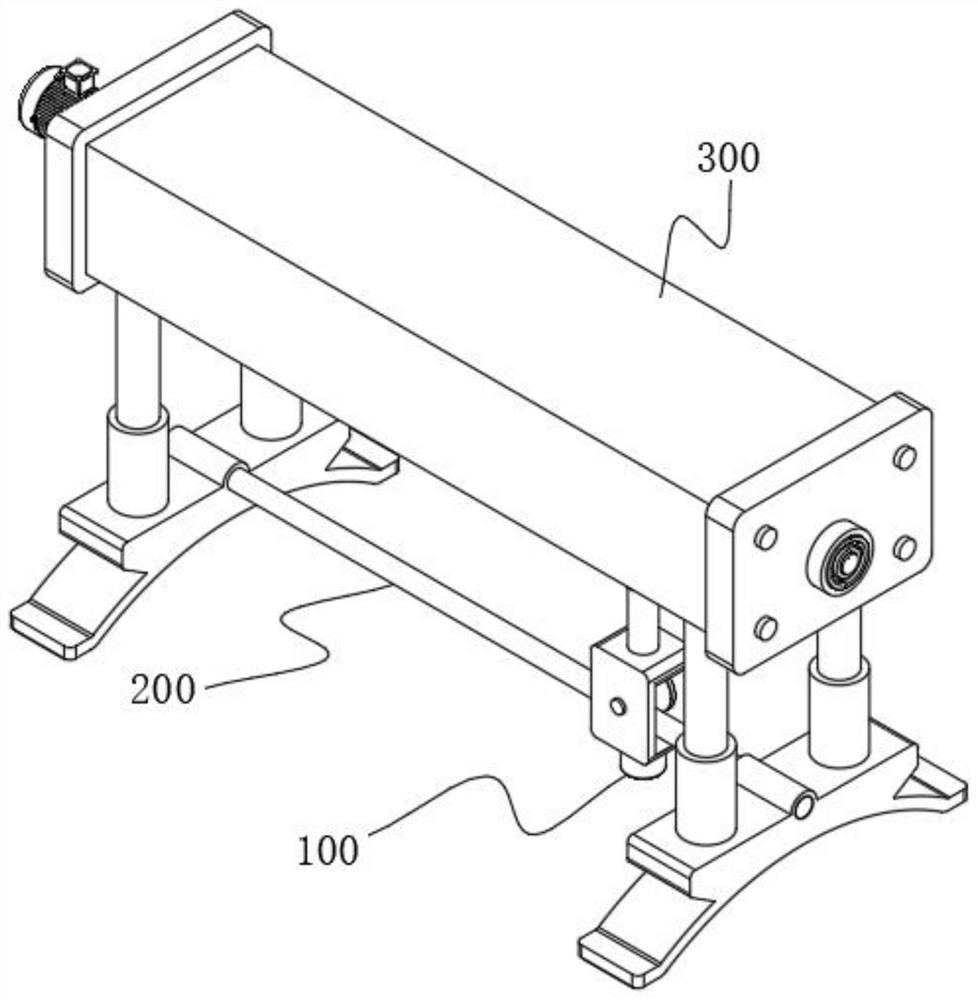

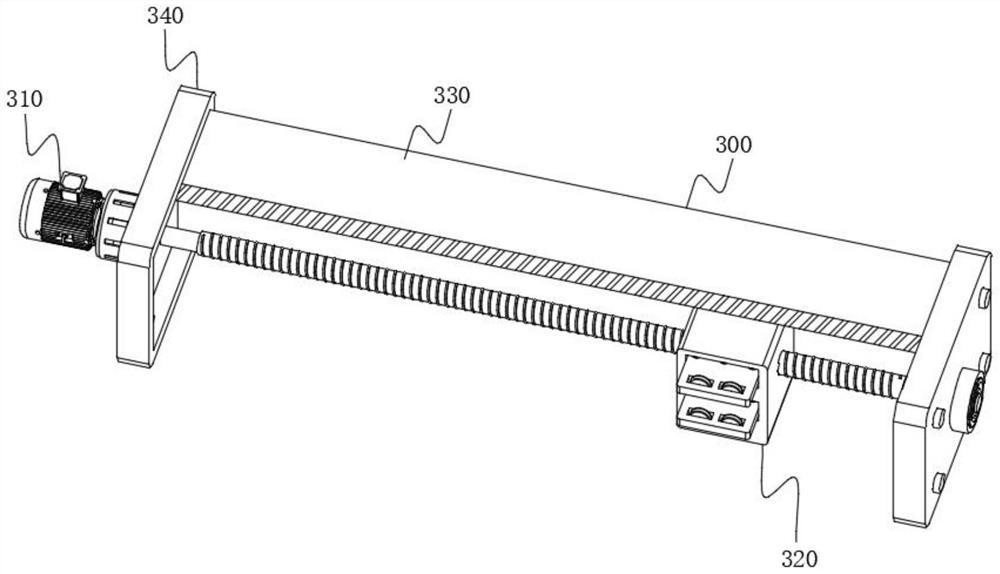

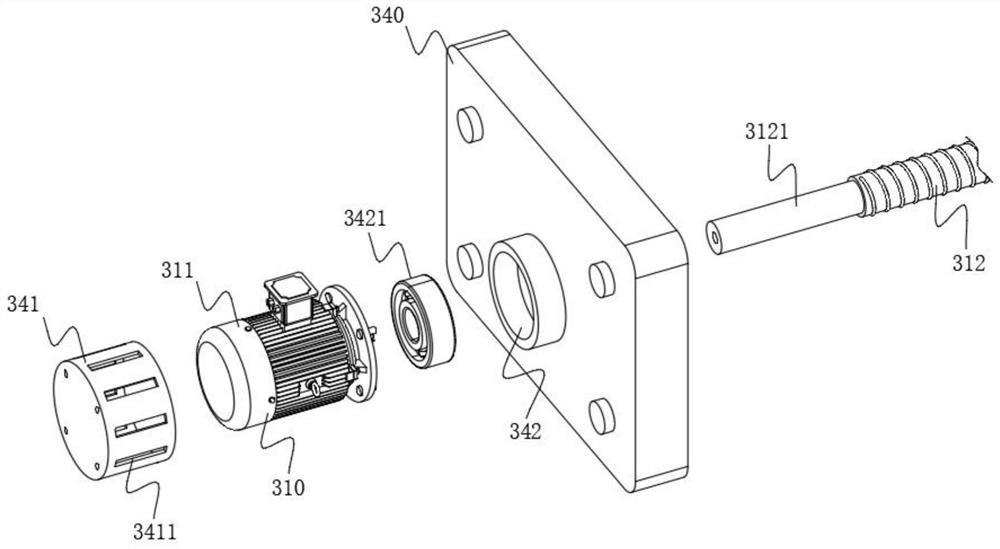

[0062] The present invention provides a friction welding spindle head based on support bar type lateral movement, please refer to Figure 1-Figure 10 , including a spindle head 100, a traverse mechanism 200 and a transmission mechanism 300 arranged on the top of the traverse mechanism 200, the traverse mechanism 200 includes a support rod 210, and support seats 220 are provided at both ends of the support rod 210, and the support seat 220 includes Support block 221, the middle position of the top of support block 221 is provided with insertion hole 2211, and support bar 210 is plugged with insertion hole 2211, thereby supports and fixes support bar 210 by support block 221, and the top of support block 221 is provided with Support rod 222, and support rod 222 is fixedly connected with transmission frame 330, and transmission frame 330 is supported by support rod 222, and transmission mechanism 300 comprises power unit 310 at least, and power unit 310 comprises motor 311, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com