Reelpipe feeding device and paper reeling machine

A technology of rolling paper and driving device, which is applied in the direction of winding strips, transportation and packaging, thin material handling, etc. performance, avoid dislocation or drive dislocation, and improve the stability of the top tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

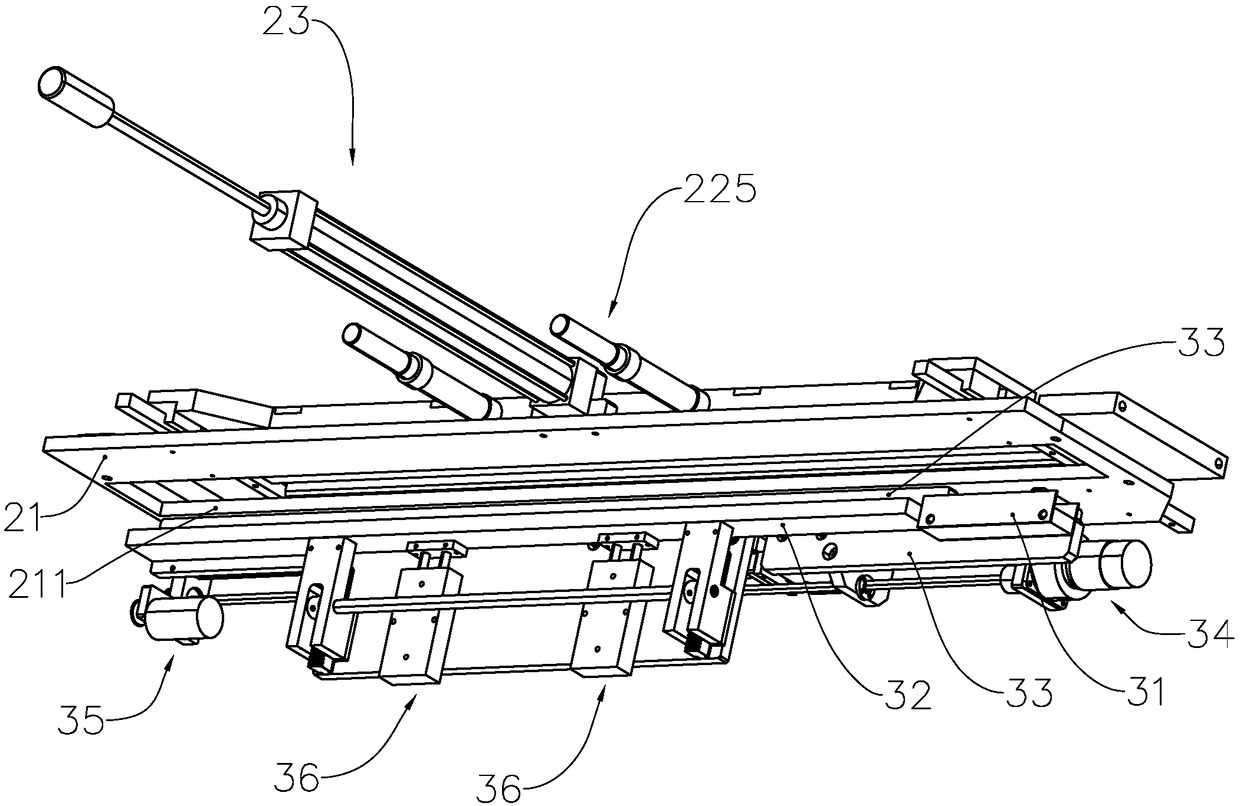

[0052] refer to Figure 14 , in the case of the above-mentioned embodiment, the present embodiment adds a sleeve 65, and the ejector rod of the ejector rod assembly 6 is sequentially sleeved with a first bearing 62, a sleeve 65, a plurality of second bearings 63 and end rods from the inside to the outside. Cover 64. The pipe sleeve 65 is sleeved on the end of the rod body 61, the pipe sleeve 65 is located between the first bearing 62 and the second bearing 63, the outer diameter of the pipe sleeve 65 is smaller than the outer diameter of the second bearing 63, and the axial length of the pipe sleeve 65 greater than the axial length of the second bearing 63 .

[0053] It can be seen from the above that the coiled tubes are pushed from the feeding rack to the carrier in a row, and after being pushed to a preset length, the carrier is driven to move along the direction of the coiled tube through the load-bearing drive assembly, and the distance between the carrier frame and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com