Warp loom guide bar assembly

A warp knitting machine and bar technology, which is applied in the field of warp knitting machine bar devices, can solve the problems of limited number of bars and failure to meet weaving requirements, and achieve cost reduction, stable transverse movement of bars, and improved linearity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

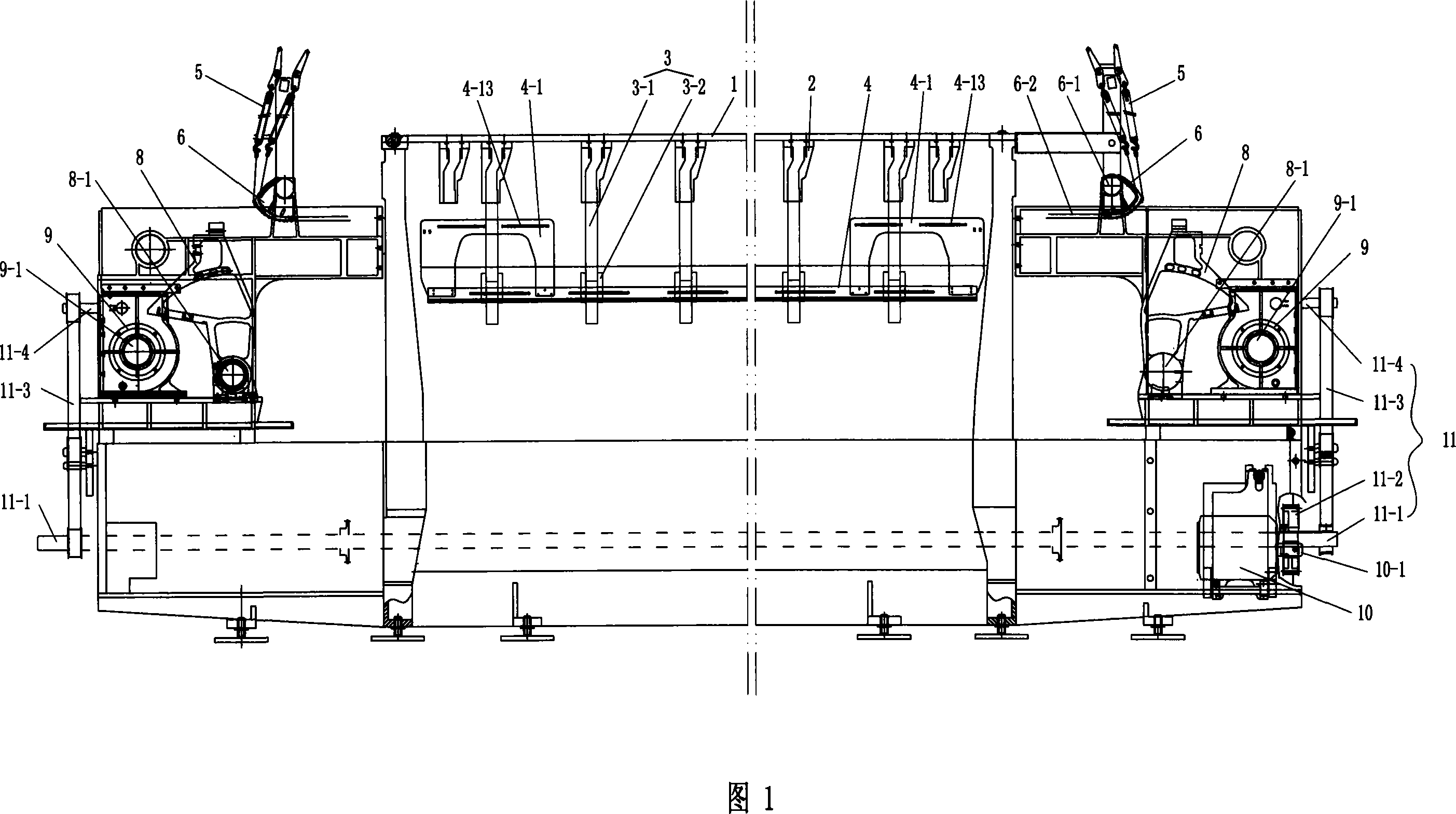

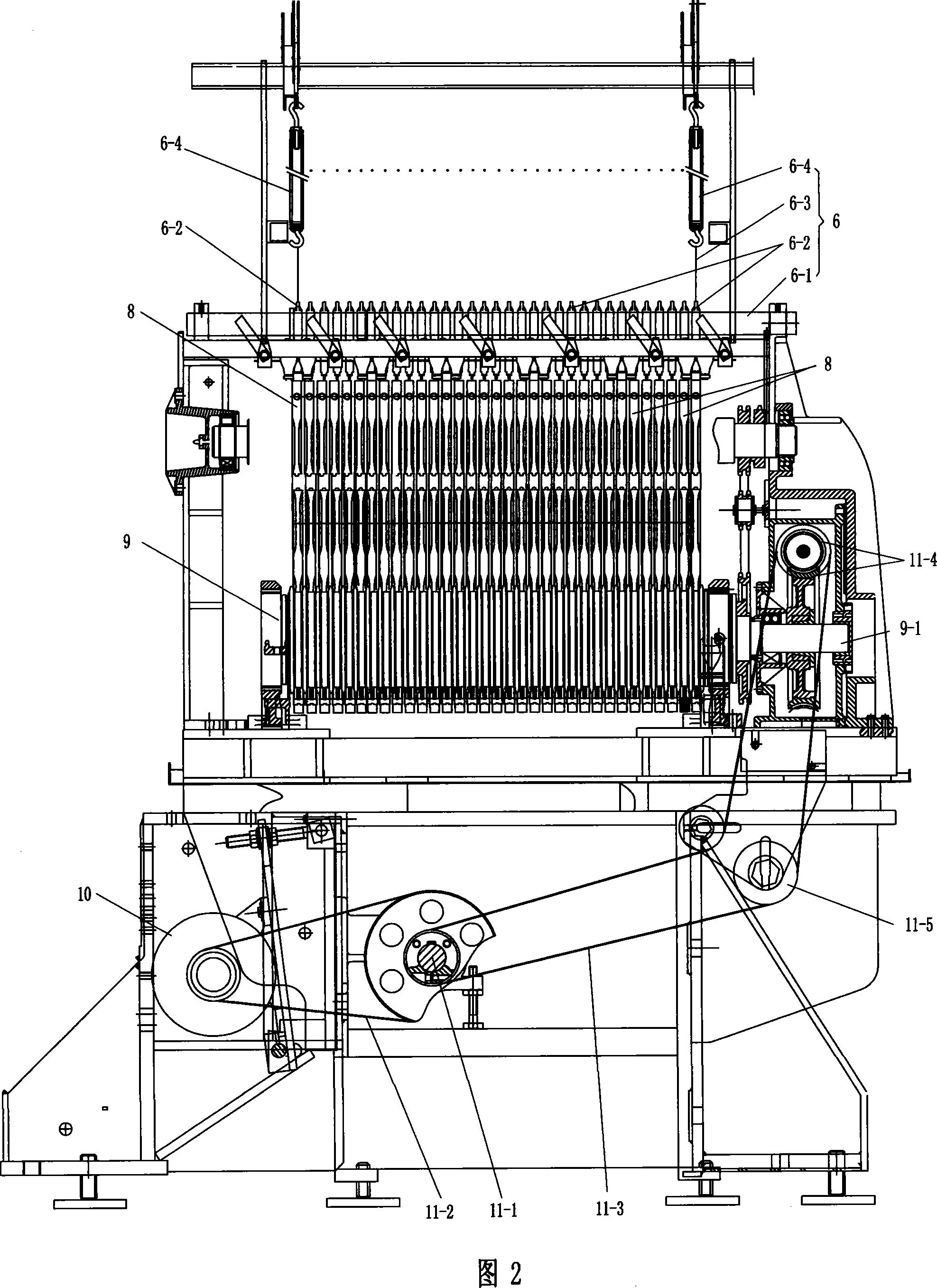

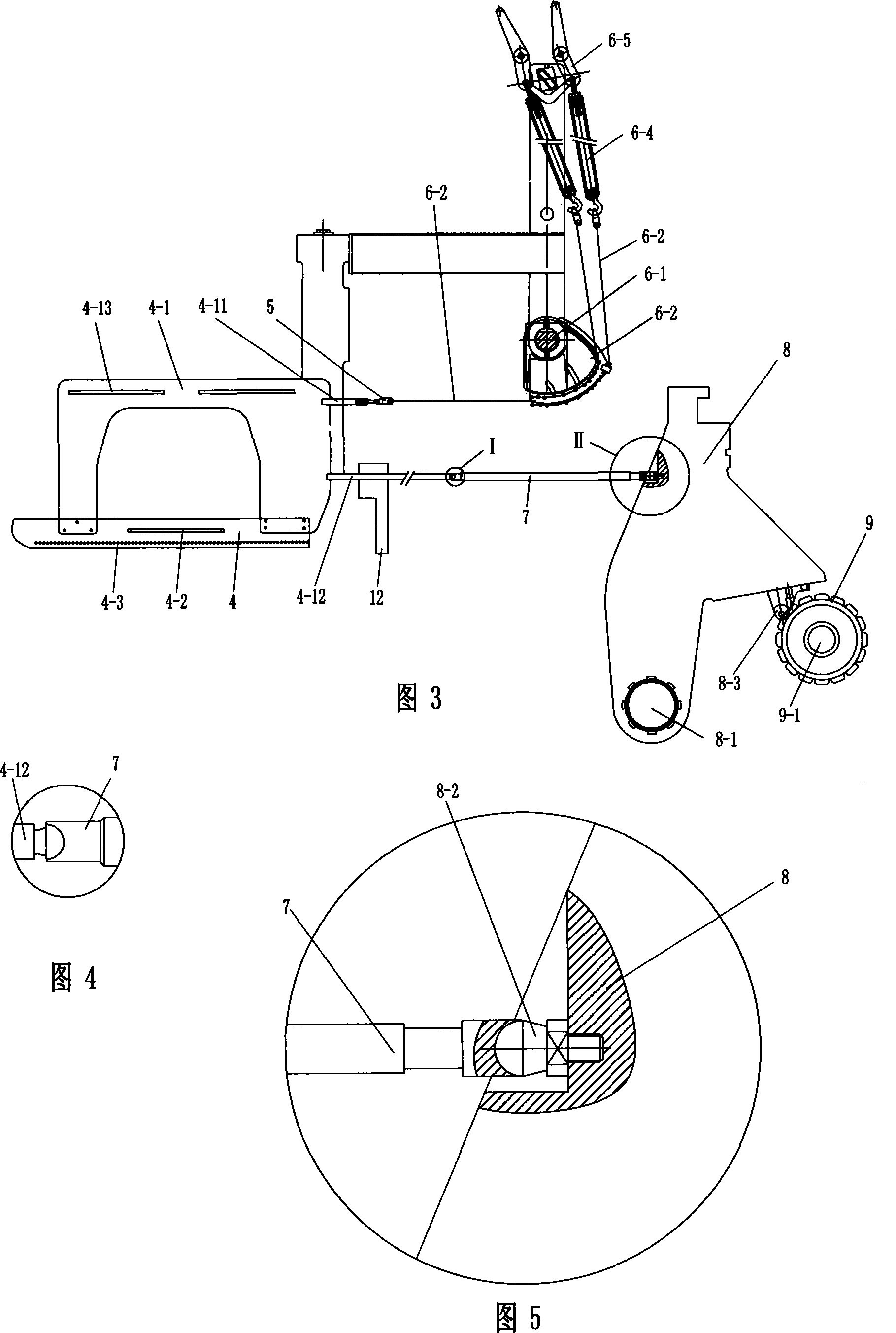

[0030] See Fig. 1 and Fig. 5, the present invention has the tension frame support 2 that is orderly fixed on the frame crossbeam 1, is connected to the bar fixing frame 3 at the bottom of each tension frame support 2, and each bar fixing frame 3 is Slidingly connected comb bar 4 and knitting pattern cylinder 9 and motor 10. Described knitting drum 9 is 2, and 2 knitting drums 9 are respectively arranged on the left and right sides of the frame, and knitting drum shaft 9-1 is supported by the frame, in addition, also respectively set on the left and right sides of the frame There is a swing arm shaft 8-1 supported by the frame.

[0031] The comb bar 4 is a steel sheet comb bar, and its thickness h is 1.8-2.5 mm, generally 2 mm. The comb 4 is divided into two groups according to a certain rule, and the single interval of the comb can be divided into two groups, that is, divided into two groups with odd and even positions, and the combs arranged at 1, 3, and 5 odd positions are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com