Servo drawer stereo garage

A three-dimensional garage and drawer-type technology, which is applied in the direction of buildings, building types, and buildings where cars are parked, can solve the problems of ineffective use of space, narrow applicable areas, and high construction costs of garages, achieving low construction and subsequent maintenance costs , Reduce the probability of damage, the effect of smooth traversing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

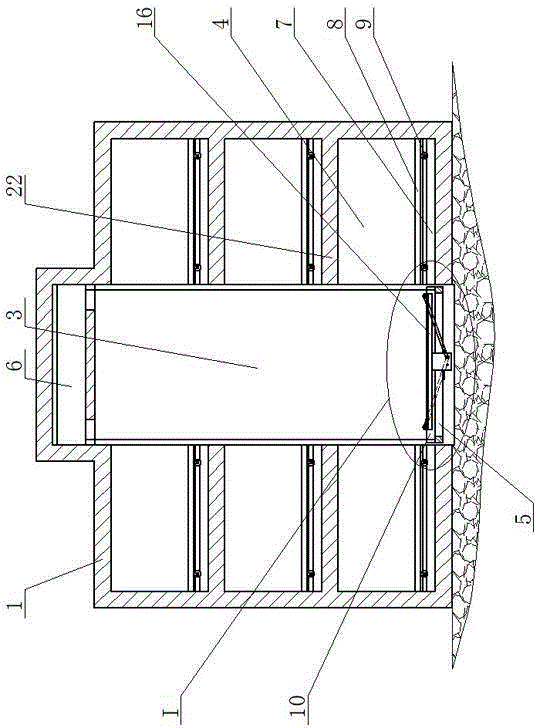

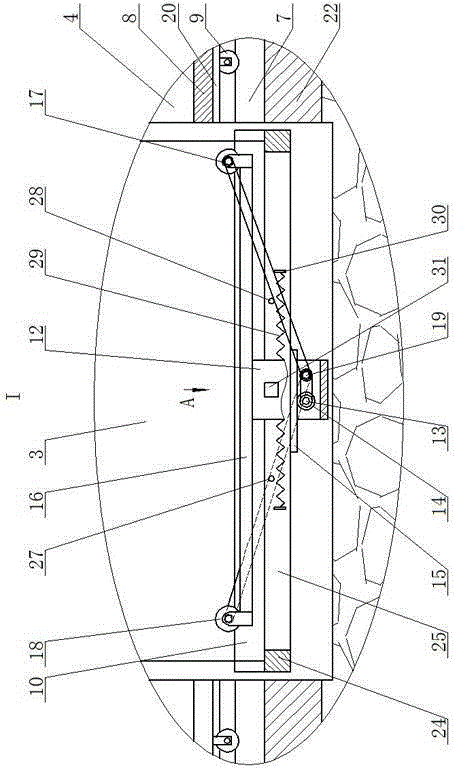

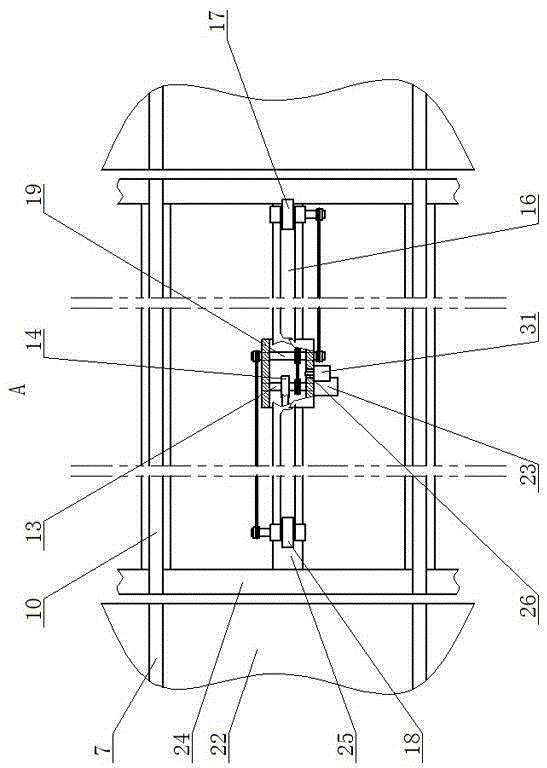

[0009] The servo drawer-type three-dimensional garage of the present invention comprises a garage main body 1, an elevator shaft 3 is arranged in the middle of the garage main body 1, and a lifting frame 5 is arranged in the elevator shaft 3, and the lifting frame 5 is connected with the hoist 6 through a sling, and each side of the elevator shaft 3 is There are at least 2 floors of floor boards 22, storehouses 4 are arranged on each floor board 22, the entrances of each storeroom 4 are all facing the elevator shaft 3, and a vehicle-carrying board 8 is arranged in each warehouse 4, and guide wheels are provided at the bottom of the car-carrying board 8 9. The bottom of the storehouse 4 is provided with a fixed guide rail 7, and the guide wheels 9 walk along the fixed guide rail 7. The lifting guide rail 10 is arranged on the top surface of the lifting frame 5, and the lifting guide rail 10 can be connected with the fixed guide rails 7 in the storeroom 4 on both sides during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com