Continuous production equipment for organic silicon resin paint film and continuous production method

A technology for producing equipment and resin paint, applied in the field of continuous production equipment of silicone resin paint film, can solve problems such as low production efficiency of paint film, and achieve the effects of improving the uniformity of painting, broadening the scope of painting, and stabilizing the speed of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

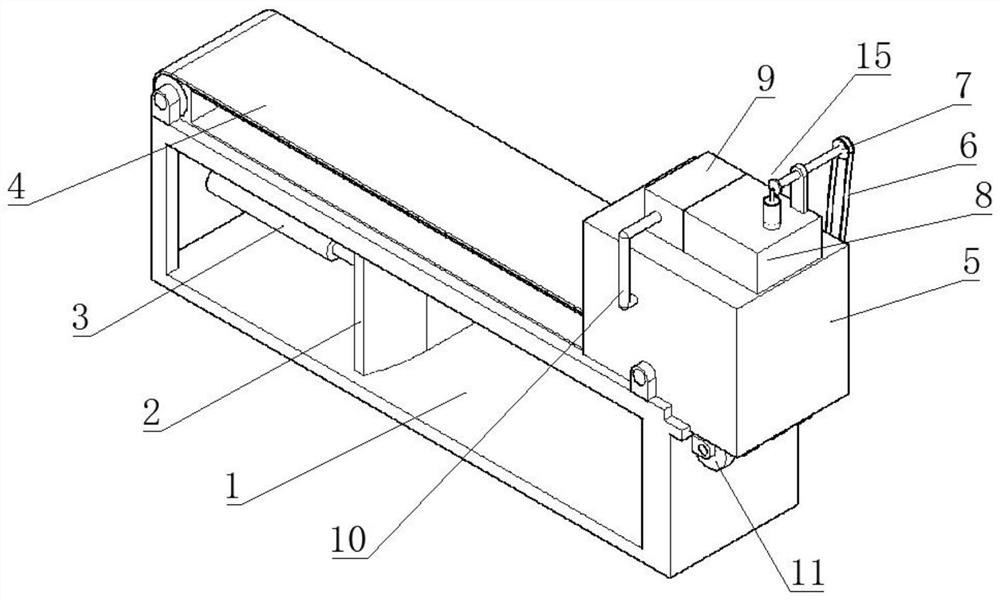

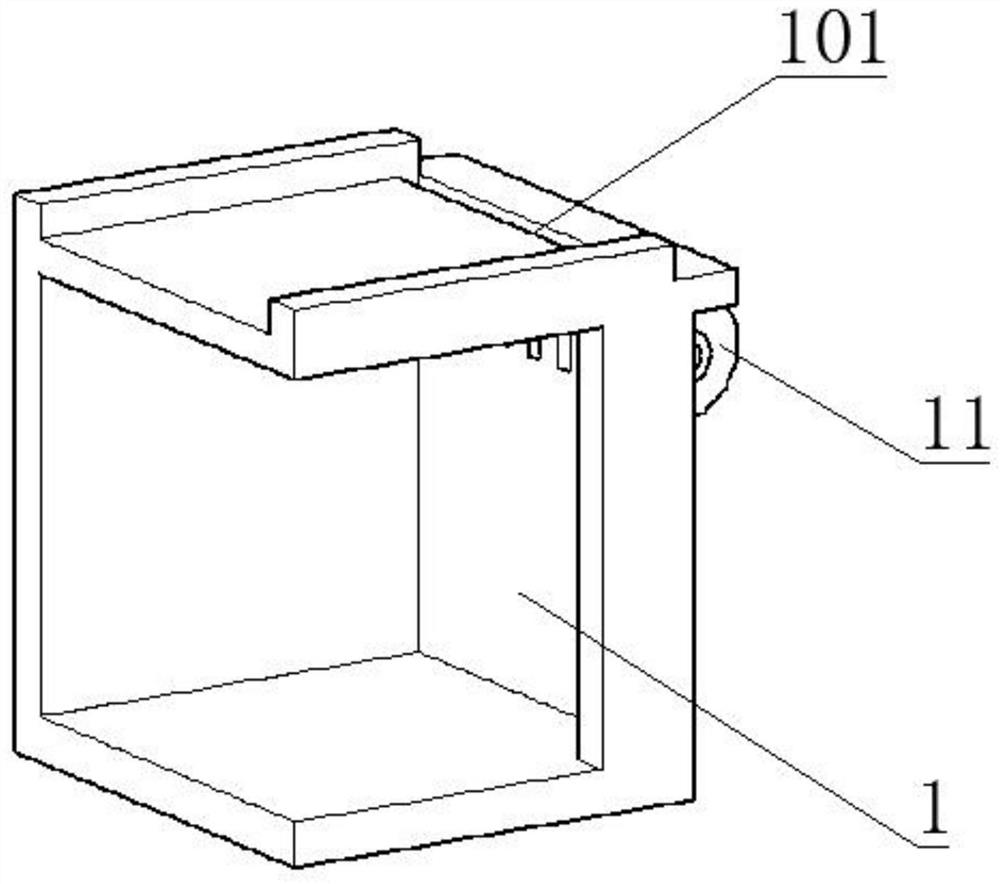

[0033] like Figure 1-6 As shown, a silicone resin paint film continuous production equipment includes a plate feeding mechanism, the side of the plate feeding mechanism is connected to a spraying mechanism, the spraying mechanism is connected to the material box 8, and the plate feeding mechanism includes a sheet material tank 1, which is located in the plate material tank 1 The side is provided with a plate delivery trough 101, the side of the plate trough 1 is rotated and connected with a plate delivery wheel 11, the top of the plate trough 1 is connected with a conveyor belt 4, and a pressing mechanism is arranged on the side of the plate trough 1, and the plate delivery wheel 11 is connected to the material box. 8. Pneumatic mechanism 15 transmission connection on the top;

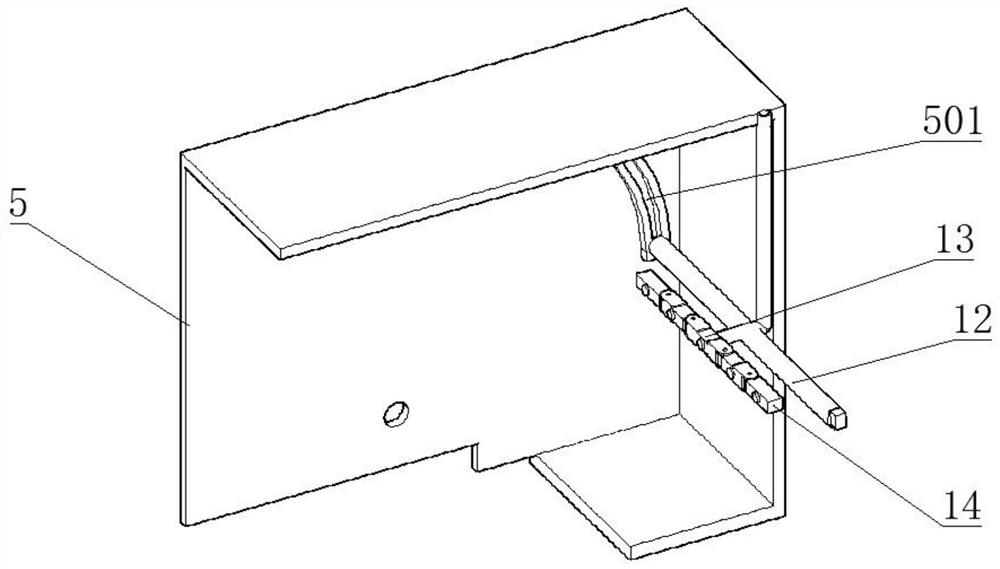

[0034] The spraying mechanism includes a connecting frame 12 that is rotatably connected to the plate tank 1, and the connecting frame 12 is fixedly connected with a nozzle, and the nozzle communicate...

Embodiment 2

[0039] like Figure 1-6As shown, a silicone resin paint film continuous production equipment includes a plate feeding mechanism, the side of the plate feeding mechanism is connected to a spraying mechanism, the spraying mechanism is connected to the material box 8, and the plate feeding mechanism includes a sheet material tank 1, which is located in the plate material tank 1 The side is provided with a plate delivery trough 101, the side of the plate trough 1 is rotated and connected with a plate delivery wheel 11, the top of the plate trough 1 is connected with a conveyor belt 4, and a pressing mechanism is arranged on the side of the plate trough 1, and the plate delivery wheel 11 is connected to the material box. 8. Pneumatic mechanism 15 transmission connection on the top;

[0040] The pneumatic mechanism 15 includes a one-way valve fixed on the top of the material box 8, the top of the one-way valve communicates with the cylinder, the sliding plug rod in the cylinder is c...

Embodiment 3

[0044] like Figure 1-6 As shown, a silicone resin paint film continuous production equipment includes a plate feeding mechanism, the side of the plate feeding mechanism is connected to a spraying mechanism, the spraying mechanism is connected to the material box 8, and the plate feeding mechanism includes a sheet material tank 1, which is located in the plate material tank 1 The side is provided with a plate delivery trough 101, the side of the plate trough 1 is rotated and connected with a plate delivery wheel 11, the top of the plate trough 1 is connected with a conveyor belt 4, and a pressing mechanism is arranged on the side of the plate trough 1, and the plate delivery wheel 11 is connected to the material box. 8. Pneumatic mechanism 15 transmission connection on the top;

[0045] The pressing mechanism includes a push plate 2 that is slidably connected in the sheet material tank 1, the other side of the push plate 2 is connected to the end of the sheet material tank 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com