High-degree-of-freedom self-centering painting mold

A self-centering, degree-of-freedom technology, applied in electrical components, circuits, insulation of conductors/cables, etc., can solve the problems of reducing the self-positioning effect of enameled wires, aggravating bending or abrasion of enameled wires, poor automatic positioning effect, etc. Self-positioning effect, improving paint uniformity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

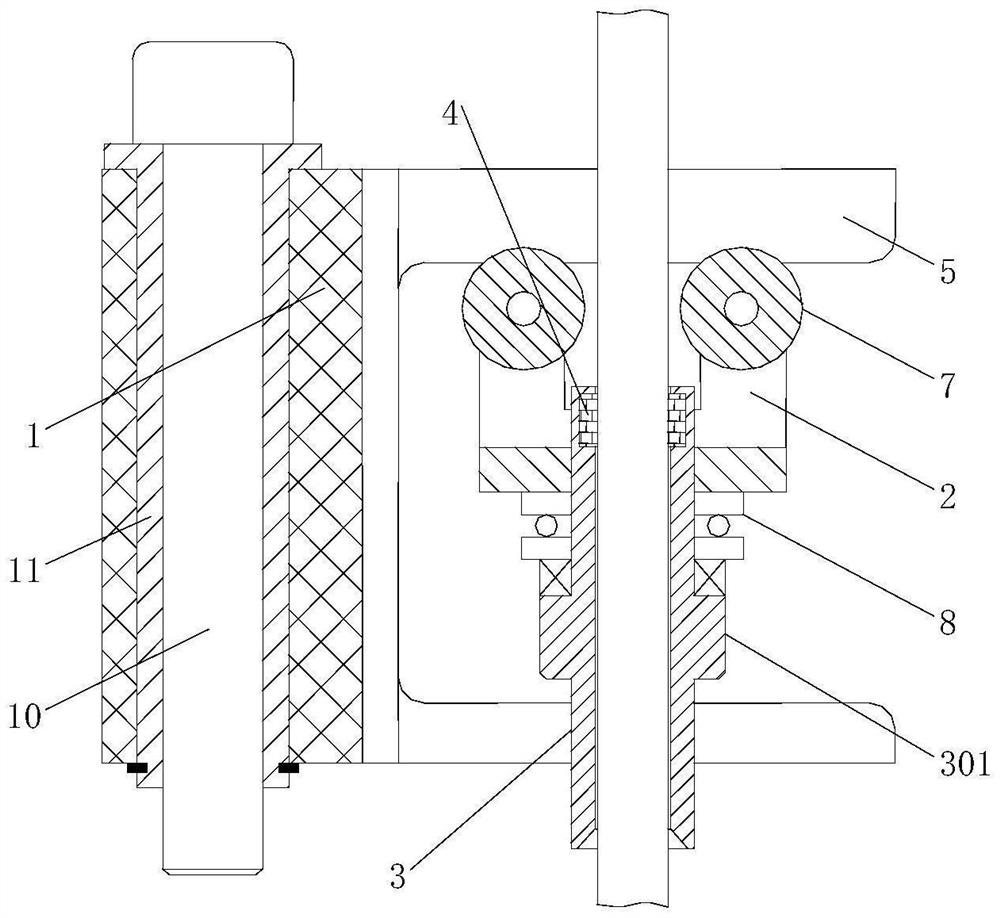

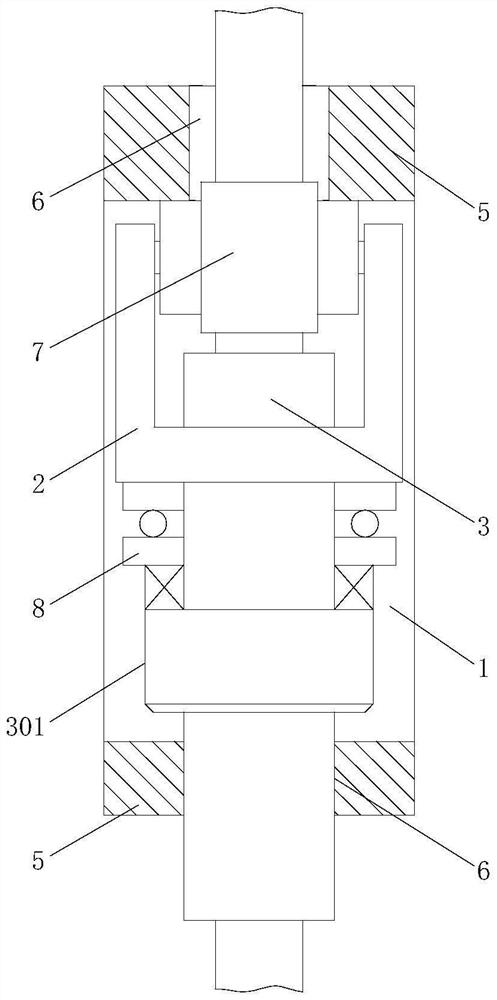

[0025] Example 1. A high degree of freedom self-centering paint mold, constituted as figure 1 with 2 As shown, it includes the positioning rod connected to the vertical painting machine. The positioning rod is located between the bottom guide rail and the upper guide roller of the vertical painting machine. The external rotation of the positioning rod is connected with the painting formwork 1, and the painting formwork 1 The upper rolling is connected with a painting mold base 2, and a mold cover 3 is arranged on the painting mold base 2. The upper end of the mold cover 3 is connected with a vertical mold core 4. Pass through the mold core 4 and enter the upper guide roller; the length of the mold sleeve 3 is 30mm, and the length of the mold core 4 is 3-5mm.

[0026] Both sides of described painting formwork 1 are all provided with slideway 5, and the middle part of slideway 5 is provided with chute 6, and one end of described painting mold base 2 is connected with rolling w...

Embodiment 2

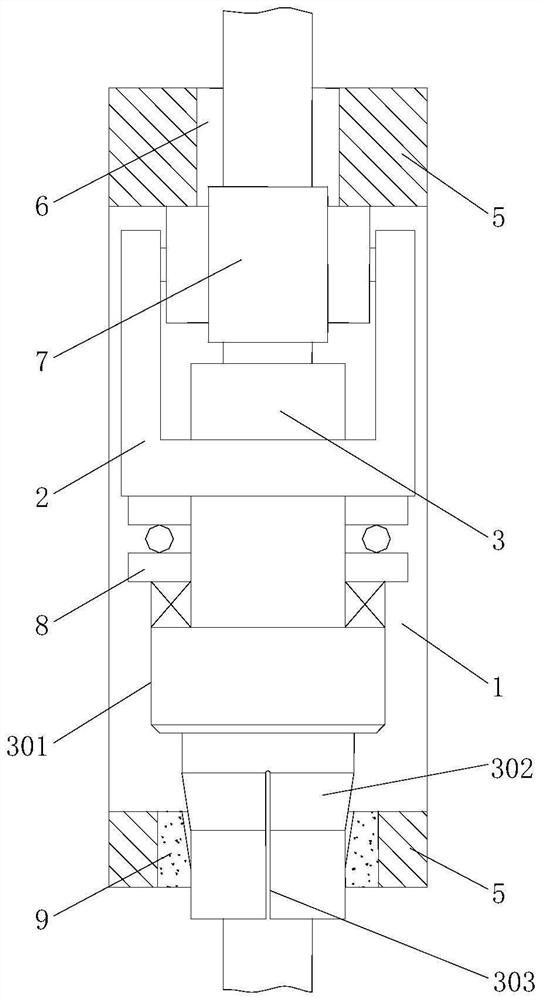

[0031] Example 2. A high degree of freedom self-centering paint mold, constituted as figure 1 with 3As shown, it includes the positioning rod connected to the vertical painting machine. The positioning rod is located between the bottom guide rail and the upper guide roller of the vertical painting machine. The external rotation of the positioning rod is connected with the painting formwork 1, and the painting formwork 1 The upper rolling is connected with the painting mold base 2, and the coating mold base 2 is provided with a mold cover 3, and the upper end of the mold cover 3 is connected with a vertical mold core 4, and the enameled wire is stretched out from the bottom guide rail when routing. Pass through the mold core 4 and enter the upper guide roller; the length of the mold sleeve 3 is 30mm, and the length of the mold core 4 is 3-5mm.

[0032] Both sides of described painting formwork 1 are all provided with slideway 5, and the middle part of slideway 5 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com