A device for painting wooden panels for furniture

A technology for wood boards and furniture, applied in the direction of devices, coatings, etc. for applying liquid to the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

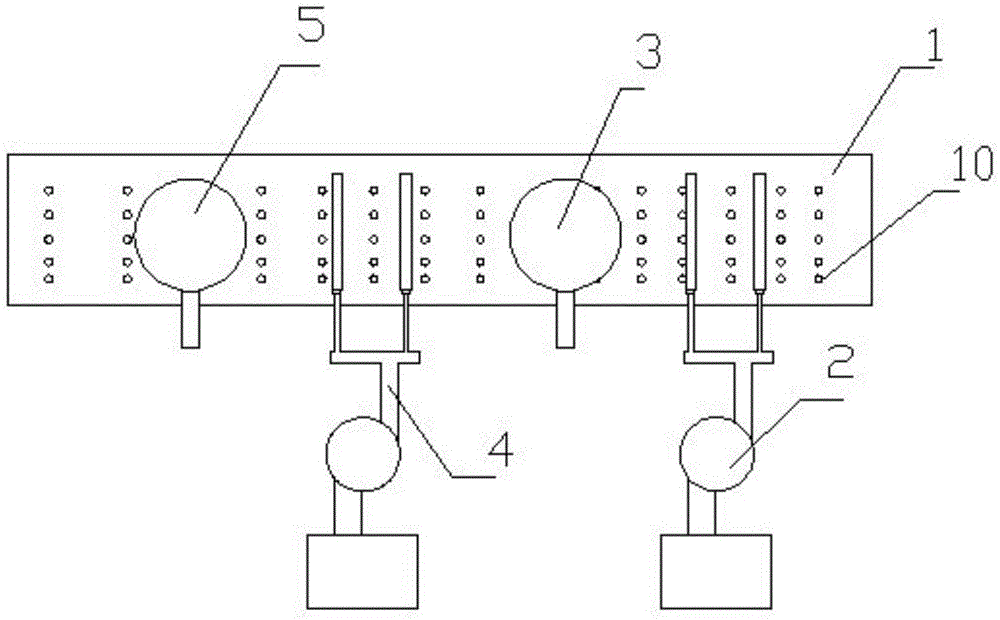

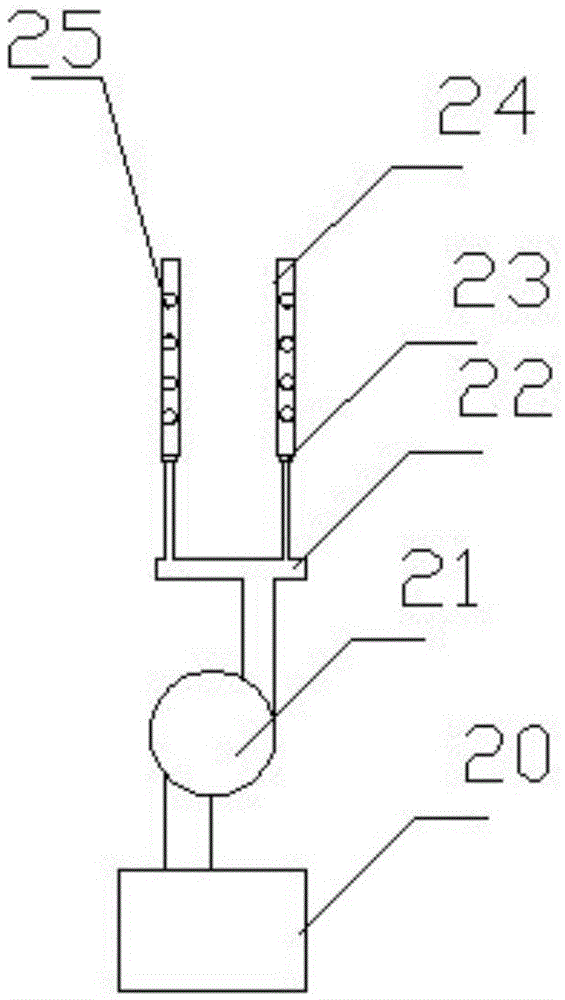

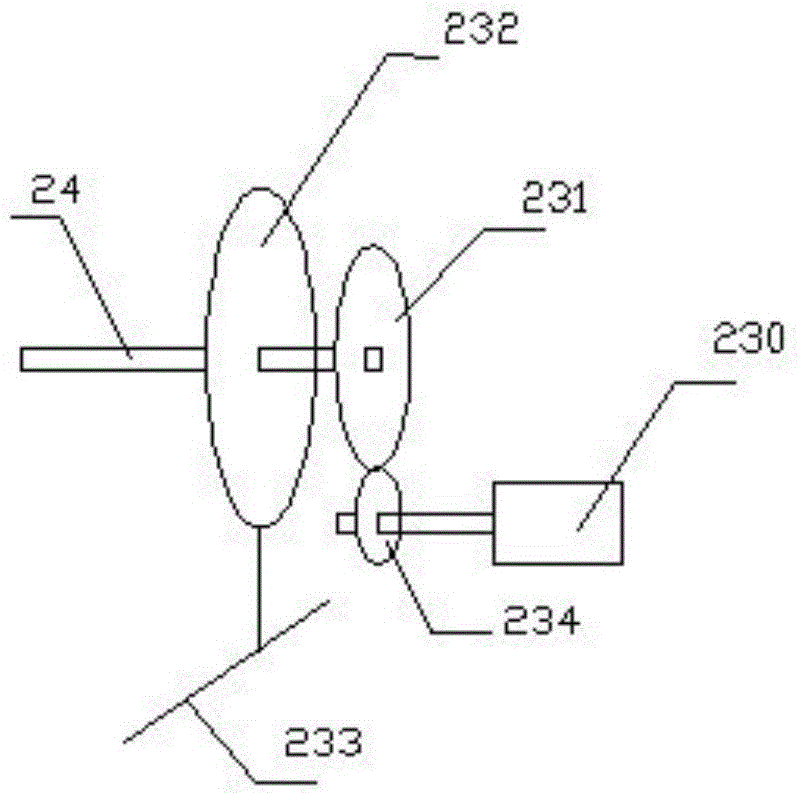

[0036] The present invention includes a conveyor belt 1, a washing mechanism 2, a first drying mechanism 3, a painting mechanism 4 and a second drying mechanism 5, and the water washing mechanism 2, the first drying mechanism 3, the painting mechanism 4 and the second drying mechanism The mechanism 5 is arranged on one side of the conveyor belt 1. According to the moving direction of the conveyor belt 1, the washing mechanism 2 is located in front of the first drying mechanism 3, the painting mechanism 4 is located behind the first drying mechanism 3, and the second drying mechanism 5 is located in the Paint spraying mechanism 4 rear. The conveyor belt of the present invention transports the wooden boards that need to be painted to the cleaning device. After cleaning by the cleaning device, impurities such as dust and solid particles on the surface of the wooden boards are washed away to prevent these impurities from affecting the painting effect, and then the conveyor belt tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com