Connecting rod and plunger connecting mechanism of press

A technology of connecting mechanism and press, which is applied in the field of mechanical press to achieve the effect of solving the problem of easy breaking and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

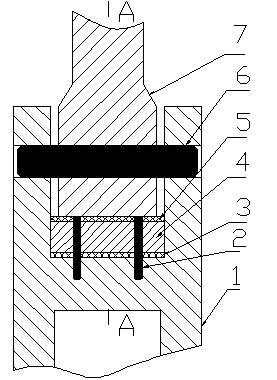

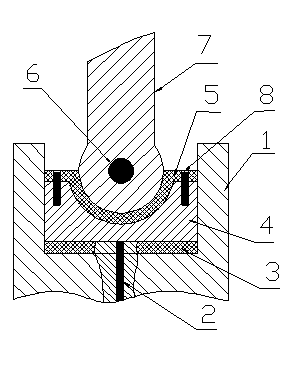

[0009] The connection mechanism between the connecting rod and the plunger of the press according to the present invention includes: a plunger 1, a fixed pin 2, an adjusting gasket 3, a support seat 4, a copper tile 5, a pin shaft 6, a connecting rod 7, and a pin 8. The bottom of the middle of the two lifting lugs of the plunger 1 is provided with an adjustment gasket 3, and the upper end of the adjustment gasket 3 is provided with a support seat 4, and the adjustment gasket 3 and the support seat 4 are fixed on the plunger 1 together with the fixing pin 2. The two lifting lugs open the middle bottom of the gear, and a copper tile 5 is arranged in the upper semicircular opening of the supporting seat 4. The copper tile 5 is fixed with the supporting seat 4 with a pin 8. The two lifting lugs of the plunger 1 In the middle of opening the gear, pin 6 is used to articulate connecting rod 7 movably, and the arc portion at the bottom of connecting rod 7 is in close contact with the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com